Полипропиленовое синтетическое макроволокно армированное

- Категории: Masonry Materials >>>

- Поставщик: Shandong,Luke,Composite,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

Synthetic Polypropylene Macro Fiber for Concrete Reinforcement

conservation.

PP macro fiber can be used instead of steel fiber to enhance the crack resistance of cement concrete and significantly improve the toughness and flexural of concrete. Because of special shape, PP macro fiber has good combination with concrete and strong bond.

Quality Compliance EN14889-2

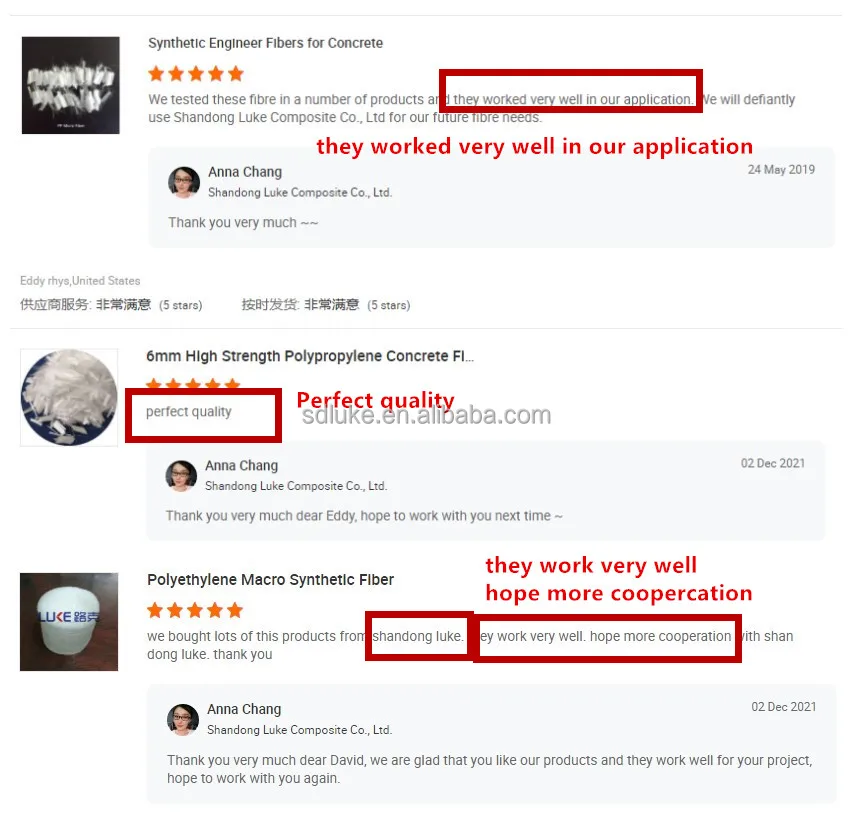

Customer Feedback

Specification

item | Polypropylene Macro Fiber |

Warranty | 1 Year |

After-sale Service | Online technical support, Onsite Inspection, Free spare parts, Return and Replacement |

Project Solution Capability | total solution for projects |

Application | Mall, Hotel, all construction |

Design Style | Modern or as your request |

Place of Origin | China |

Shandong | |

Brand Name | LUKE |

Model Number | PP Macro Fiber |

Application | Concrete Usage |

Usage | Concrete Strength Reinforcement |

Appearance | White, black, grey |

Keywords | Polypropylene Fiber Concrete Fibers |

Advantage | High Stability |

Certificate | ISO 9001, we pass SGS, TUV |

PACKAGE | plastic / water soluble packing |

DENSITY | 0.91+/-0.01g/cm3 |

Feature | good dispersion |

Length | 20-60mm |

Feature

Increased flexural toughness concrete

Enhanced impact resistance

Extended service life

Increased ductility

Potential for increased joint spacing Easy to transport, store and handle Chemically inert and stable

Maximum design freedom

CO2 emission savings

No wear-out of equipment

Increased speed of construction combined with improved safety on site

Application

3. To reduce the leakage of concrete

4. To protect steel from corrosion5. To improve the durability of concrete structures

6. Increase the wear resistance of concrete

7. Increasing the concrete crack

resistance, flexural strength, increased toughness of concrete, to extend the life of concrete binder

Manufacturing Technique

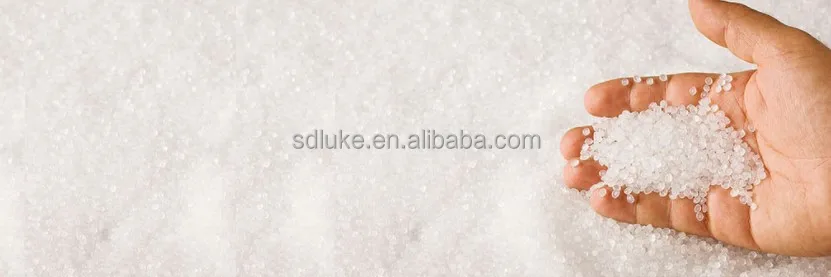

100% new Polypropylene + Professional Manufacturing + Strict Inspection = Quality Product

We have two packing, plastic or water soluble bag.

Plastic packing : 1kg/plastic bag, 10kgs/PP woven bag

Please see the pictures :

This is our water soluble packing.

This packing save space, load more tons in one container, and very simple to use, just put into concrete, save labor cost and sea freight cost.

Company Profile

Shandong LUKE Composite Co., Ltd is with more than ten years working in the field of Synthetic Concrete Fibers, also has a prefessional team for export business, located in Taian, Shandong China which is the plastic production base in China, our concrete fibers have been exported to more than 30 nations and regions, such as Southeast Asia, Australia, North America, Europe, Middle East and Africa–

- Polypropylene micro fiber

- Polypropylene macro fiber

- Polypropylene mesh fiber

- Polypropylene twist fiber

Alibaba Gold Plus supplier, Member of Alibaba Trade Assurance (amount USD579,000 for now)

Passed SGS TÜV SÜD CE Certification, ISO9001, ISO14001 and OHSAS18001 approved.

LUKE purpose : supply qualified products, competitive price and efficient service, expecting toachieve the goal of long term cooperation and mutual benefits.

Quality is our culture, Welcome to visit our company !

- Polypropylene micro fiber

- Polypropylene macro fiber

- Polypropylene mesh fiber

- Polypropylene twist fiber

Alibaba Gold Plus supplier, Member of Alibaba Trade Assurance (amount USD579,000 for now)

Passed SGS TÜV SÜD CE Certification, ISO9001, ISO14001 and OHSAS18001 approved.

LUKE purpose : supply qualified products, competitive price and efficient service, expecting toachieve the goal of long term cooperation and mutual benefits.

Quality is our culture, Welcome to visit our company !

Thank you for visiting, welcome to inquire !

Anna Chang /Export Manager

Mob : +86-18263808154 (Wechat/WhatsApp)

Email : sdluke(at)hotmail.com