Производитель HENGLV новое профессиональное модифицированное биоразлагаемое сырье биоразлагаемые

- Категории: Plastic Raw Materials >>>

- Поставщик: Danyang,Henglv,New,Material,Packing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

PLA/PBAT Material Overall Solution Provider

100% Biodegradable & Compostable

Product Name:

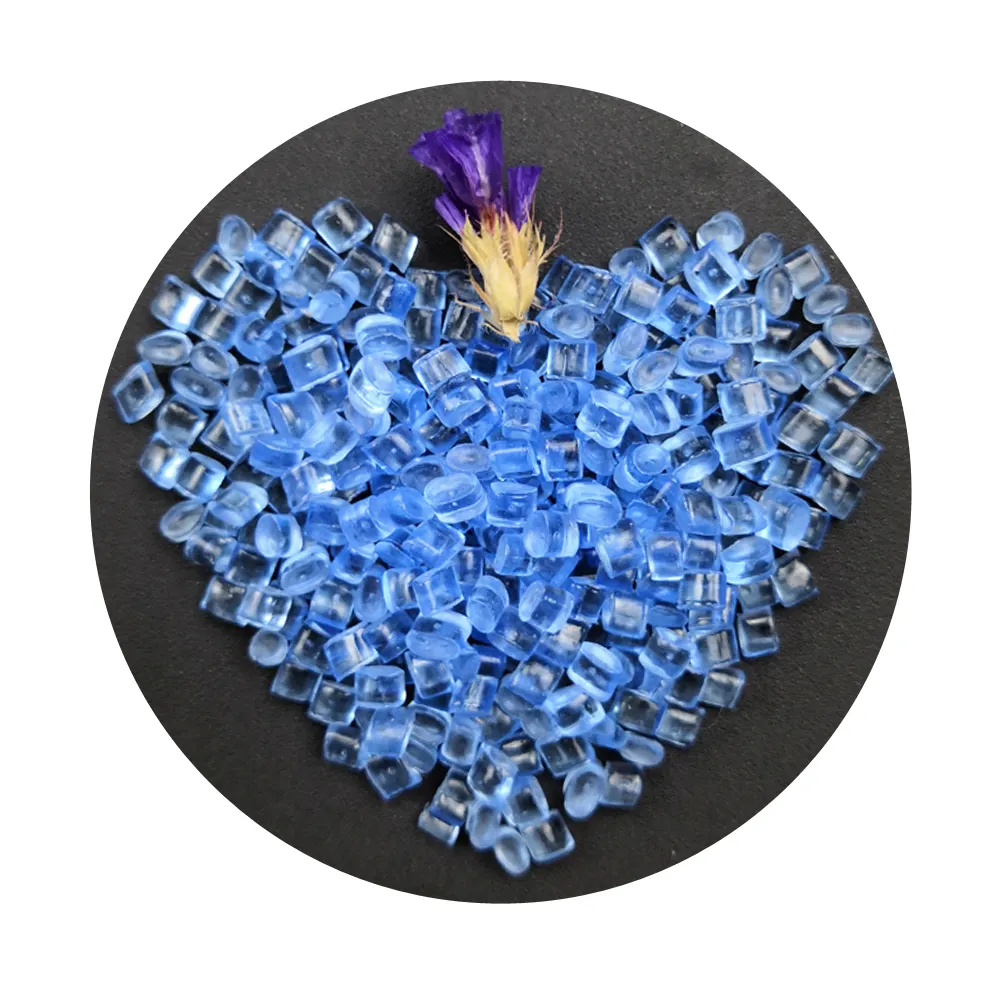

PLA Biodegradable Granules

Place of Origin: Jiangsu, China

Product Features: biodegradable, healthy and environmentally friendly, the plastic products produced have strong toughness

Processing method: blow molding with ordinary LDPE self-sealing bag film blowing machine

Product Usage:Takeaway lunch boxes, plastic wrap, garbage bags, plastic bags and other plastic products

Performance | Test Conditions | Unit | Numerical Value |

Density | ISO 1138 | g/cm³ | 1.26-1.3 |

Hardness | ASTM-D2240 | D | 50-60 |

Melt index (2.16kg-190℃) | ISO 1133 | g/min | 2.0-4.0 |

Rongcheng | ASTM-D3428 | ℃ | 95-150 |

Melting per unit mass | ASTM-D3417 | J/g | 5.0-6.0 |

Thermal decomposition temperature | ASTM-D6370 | ℃ | 260 |

Tensile strength (horizontal) | ASTM-D882 | Map | ≥25 |

Tensile strength (longitudinal) | ASTM-D882 | Map | ≥25 |

Elongation at break (horizontal) | ASTM-D882 | % | ≥500 |

Elongation at break (horizontal) | ASTM-D882 | % | ≥250 |

Tear strength (horizontal) | ASTM-D1004 | N/mm | ≥150 |

Tear strength (horizontal) | ASTM-D1004 | N/mm | ≥100 |

Usage scenario

Courier bag

Vest bag

Trash bag

Disposable tableware

Biodegradable bag with zipper

Coffee cup lids and straws

Injection molding application: PLA mixed modified degradable material can not only be molded quickly, but also is an ideal material for disposable tableware, quilts and flower pots in terms of heat resistance and safety.

Extrusion processing application: PLA mixed modified degradable material is suitable for processing on common extrusion molding machines, and can be made into transparent, heat-resistant color and other extrusion products, which can be directly degraded into carbon dioxide and water after disposal.

Film processing: There are many plastic film forming methods, among which casting, extrusion and calendering are more common. PLA mixed modified and degraded raw materials can be adapted to most traditional equipment and processed into films through various processes, such as agricultural mulching films for garbage bags and shopping bags.

Extrusion processing application: PLA mixed modified degradable material is suitable for processing on common extrusion molding machines, and can be made into transparent, heat-resistant color and other extrusion products, which can be directly degraded into carbon dioxide and water after disposal.

Film processing: There are many plastic film forming methods, among which casting, extrusion and calendering are more common. PLA mixed modified and degraded raw materials can be adapted to most traditional equipment and processed into films through various processes, such as agricultural mulching films for garbage bags and shopping bags.

Our Advantages

The Different Between Different Mateerials

raw materials | renewable resource | durable | lightweight | malleable | recycclable | biodedradable | compostable |

plastic petrolumoil | no | yes | yes | yes | yes | no | no |

biodegradable vegetable based comstarch biodegradable proprietary components | yes | yes | yes | yes | no | yes | yes |

paper&trees (are newable resource) | yes | yes | no | yes | yes | yes | yes |

Bioplastics are hope for the future of the environment

1. Different from traditional petroleum-based plastics, bio-based fully degradable materials from corn, cassava, sucrose and other renewable plant resources can replace most synthetic plastics after being mixed and modified.2. Traditional petroleum-based plastics have caused serious white pollution to the earth's ecology. Use safer and more environmentally friendly biodegradable materials to make better products, and the environment becomes better.

3. Products made of biodegradable materials are then discarded and then composted. Under the action of microorganisms, they can be degraded 100%, and the final products are carbon dioxide and water.

Company Profile

Hot Sale

Chat Us

FAQ

Q: Are you trading company or manufacturer ?

A: We are a professional manufacturer with more than 10 years production experience,our factory is in jiangsu.which have advantage in production cost,in order to offer you a better service.

Q: Do you accept small orders?

A: Yes,please feel free to contact us.In order to get more orders and give our clients more convener,we accept small order.

Q: Can you send products to my country?

A: Sure,we can.If you do not have your own ship forwarder,we can help you.

Q: How long is your production lead time?

A: It depends on product and order qty.Normally,it takes us 15 days for an order with MOQ qty.

Q: Can you do OEM for me?

A: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q: How long is your delivery time?

A: Generally it is 1-5 days if the goods are in stock.or it is 20-30 days if the goods are not in stock,it is according to your order quantity and requirements.

Q: When can we get the prices?

A: We usually quote within 8 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your Email so that we will regard your inquiry priority.

A: We are a professional manufacturer with more than 10 years production experience,our factory is in jiangsu.which have advantage in production cost,in order to offer you a better service.

Q: Do you accept small orders?

A: Yes,please feel free to contact us.In order to get more orders and give our clients more convener,we accept small order.

Q: Can you send products to my country?

A: Sure,we can.If you do not have your own ship forwarder,we can help you.

Q: How long is your production lead time?

A: It depends on product and order qty.Normally,it takes us 15 days for an order with MOQ qty.

Q: Can you do OEM for me?

A: We accept all OEM orders,just contact us and give me your design.we will offer you a reasonable price and make samples for you ASAP.

Q: How long is your delivery time?

A: Generally it is 1-5 days if the goods are in stock.or it is 20-30 days if the goods are not in stock,it is according to your order quantity and requirements.

Q: When can we get the prices?

A: We usually quote within 8 hours after we get your inquiry.If you are very urgent to get the price,please call us or tell us in your Email so that we will regard your inquiry priority.

Похожие товары

Шарики из пенопласта, шарики из пенопласта для рукоделия

US $0.25-$0.32

Шарики из пенопласта, шарики из пенопласта для рукоделия

US $0.25-$0.32