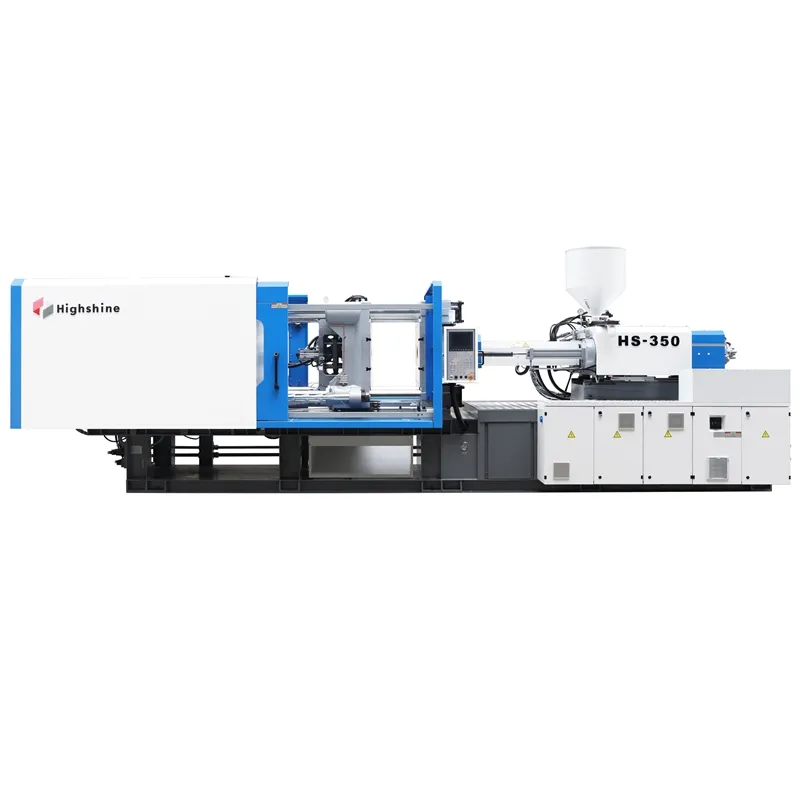

Автоматическая ЧПУ металлическая Вертикальная резиновая пресс-машина для литья под давлением от производителя пластиковых искусственных

- Категории: Injection Molding Machines >>>

- Поставщик: Aman,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Details

The overall structure is compact, the layout is reasonable,

the workshop space is saved - 20% faster than the traditional machine,

the machine movement cycle brings more product competitiveness for customers.

High stability and high precision, mold accuracy up to + 0.1mm,

injection and rotation holding position accuracy up to + 0.1mm,

product weight accuracy up to 0.2%-0.3%

injection force and adhesive resistance increased by 10%-20% compared with the traditional machine.

Using high response KEBA computer control system, so that the action in 40ms response time size pipeline design, so that the system no function to minimize consumption, for customers to bring a stronger product competitive advantage

the workshop space is saved - 20% faster than the traditional machine,

the machine movement cycle brings more product competitiveness for customers.

High stability and high precision, mold accuracy up to + 0.1mm,

injection and rotation holding position accuracy up to + 0.1mm,

product weight accuracy up to 0.2%-0.3%

injection force and adhesive resistance increased by 10%-20% compared with the traditional machine.

Using high response KEBA computer control system, so that the action in 40ms response time size pipeline design, so that the system no function to minimize consumption, for customers to bring a stronger product competitive advantage

A. Clamping unit

1.Using professional machine hinge analysis software to optimize the original BJ series machine hinges After optimization, the machine hinge opening and closing molds are smoother, which completely solves the problem that the machine hinge molds stay for a long time to open the mold.

2.The template is optimized by finite element analysis to make the deformation and strength of the template more reasonable, ensure more stable operation of the machine, and improve the accuracy of customer products

1.Using professional machine hinge analysis software to optimize the original BJ series machine hinges After optimization, the machine hinge opening and closing molds are smoother, which completely solves the problem that the machine hinge molds stay for a long time to open the mold.

2.The template is optimized by finite element analysis to make the deformation and strength of the template more reasonable, ensure more stable operation of the machine, and improve the accuracy of customer products

3.The guide of the Colin column is changed from the traditional copper sleeve guide to the high-performance, low-resistance and high-speed composite guide sleeve, and the friction coefficient is reduced from the original 0.2 to 0.02; the energy consumption of the system is greatly reduced, and the collin column is more effectively protected from heat and heat. The previous 0.2 is reduced to 0.02; the energy consumption of the system is greatly reduced, and at the same time, it is more effective to protect the colin column and heat.

4.The friction pair of the sliding foot is made of low-resistance manganese alloy steel belt, which can effectively ensure the smooth movement of the mold

B. The injection unit

1.Compared with the original BJ series and mainstream brand machines on the market, the cross-sectional area of the injection cylinder is increased by 20% to ensure that lower injection pressure is used when injecting products, which is conducive to ensuring injection accuracy and stability; at the same time, it maintains lower pipeline energy loss . For example, when a certain set of molds is produced on the original BJ machine, the actual injection pressure of the system is 100bar, and the injection pressure required for the production of the same tonnage BM machine is: 100X (1-20%) = 80bar.

2.Compared with the mainstream brand machine oil motors on the market, the oil motor is increased by one to two stages to ensure that customers always maintain a low melt pressure when producing melt glue, ensure the melt stability and the life of the oil motor.

1.Compared with the original BJ series and mainstream brand machines on the market, the cross-sectional area of the injection cylinder is increased by 20% to ensure that lower injection pressure is used when injecting products, which is conducive to ensuring injection accuracy and stability; at the same time, it maintains lower pipeline energy loss . For example, when a certain set of molds is produced on the original BJ machine, the actual injection pressure of the system is 100bar, and the injection pressure required for the production of the same tonnage BM machine is: 100X (1-20%) = 80bar.

2.Compared with the mainstream brand machine oil motors on the market, the oil motor is increased by one to two stages to ensure that customers always maintain a low melt pressure when producing melt glue, ensure the melt stability and the life of the oil motor.

3.Symmetrical distribution of double-shot transfer cylinders is used to effectively balance the injection reaction force, so that the glue injection mechanism can be injected smoothly, avoiding the defects of the single-shot transfer cylinder’s unsteady glue injection mechanism and the easy leakage of glue from the nozzle. The defect that the nozzle is easy to leak rubber

4.The dual linear guide rails are used for injection movement and injection guide structure to make the injection resistance smaller, which is beneficial to improve the injection accuracy and machine stability.

5.The optimized structural design of plasticizing components is more suitable for thermoforming of engineering plastics, color mixing and precision plastic products with glass fiber reinforced materials.

Oil System

1.Super power to improve customer productivity and profit. Compared with rival manufacturers, the size of the standard oil pump of the BM machine will exceed one to two stages

2.Optimized oil circuit design minimizes pipeline loss, resistance and vibration. Smooth machine operation and increased precision

3.The back pressure component adopts CNC back pressure to ensure more stable plasticization

4.Double hydraulic protection + electrical protection, to create a super safe machine in the industry, to ensure safe and reliable

operation of workers

5.The all-weather cooling system ensures that the oil temperature remains low and the machine runs more stably.

6.The bypass filter system ensures the cleanliness of the hydraulic system, reduces the interference of pollutants on the

hydraulic system, and improves the service life of components.

3.The back pressure component adopts CNC back pressure to ensure more stable plasticization

4.Double hydraulic protection + electrical protection, to create a super safe machine in the industry, to ensure safe and reliable

operation of workers

5.The all-weather cooling system ensures that the oil temperature remains low and the machine runs more stably.

6.The bypass filter system ensures the cleanliness of the hydraulic system, reduces the interference of pollutants on the

hydraulic system, and improves the service life of components.

C. Electrical System

1.European KEBA advanced computer control system to ensure stable, precise and efficient operation of the machine

2.Brand electrical components to ensure stability and longevity

1.European KEBA advanced computer control system to ensure stable, precise and efficient operation of the machine

2.Brand electrical components to ensure stability and longevity

D. High rigidity frame 1.Optimized by finite element analysis has extremely high rigidity, which effectively reduces the influence of frame deformation on the precision and stability of the whole machine during high-speed and high-pressure mold clamping injection E. Overall machine performance 1.Stability: The machine runs extremely smoothly, without system and pipeline impact 2.High precision: a).The mold opening accuracy can reach 0.1mm positive and negative b). The accuracy of the injection and transfer pressure positions can reach 0.01mm positive and negative c). Product weight accuracy up to 0.2%-0.3%. 3.Comprehensive speed improvement: Under the condition of ensuring strong glue injection pressure and strong glue melting torque, the speed is greatly improved, bringing direct economic benefits to customers 4. Low noise: The BM machine runs at the maximum pressure and maximum speed during the glue injection and glue melting actions, and the system noise does not exceed 73dB; compared with the factory standard of 82dB of rival manufacturers, it has a qualitative change; it brings customers a quiet factory environment 5. High responsiveness: Using the latest high-response servo energy-saving system developed by Inovance, combined with the optimized oil circuit system and high-response computer control system, the action response time is increased from the original 55ms to 35ms 6. High energy-saving: Adopting high-performance servo energy-saving system, through the optimized oil circuit design, the useless power consumption of the system is minimized, and the system can give as much energy consumption as the product really needs; finally, it will bring strong energy to customer products. Competitiveness and profit. | ||||||||