DXGF14-12-5 Автоматическая небольшая конвеерная машина для розлива газированных напиток безалкогольных напитков делая

- Категории: Industrial Machinery >>>

- Поставщик: Zhangjiagang,Grandee,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

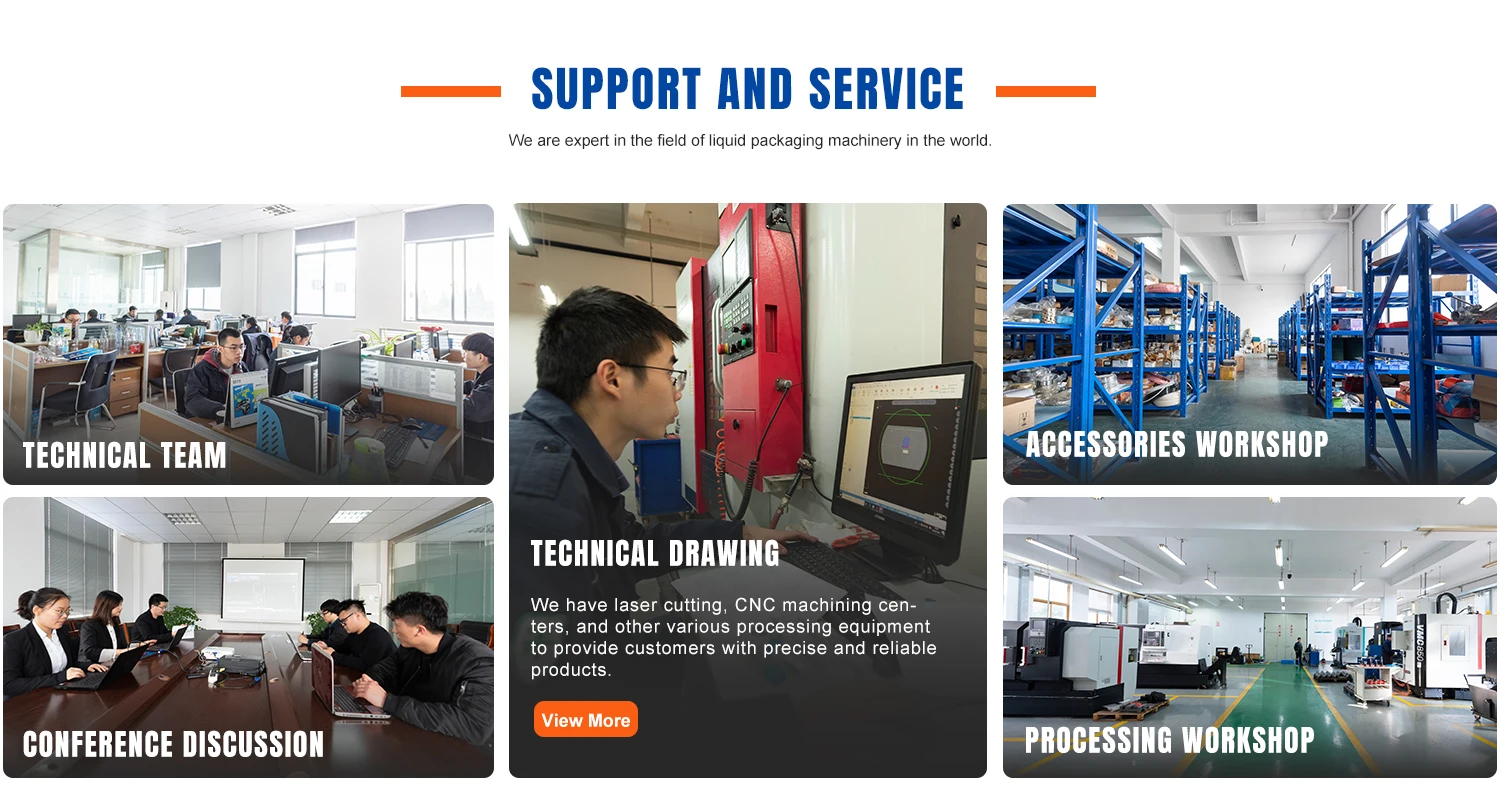

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

Products Description

Carbonated Filling Machine DXGF14-12-5

Carbonated drink filling equipment adopts bottle neck holding transmission technology to realize fully automatic bottle rinsing, pulp filling, carbonated filling and cap screwing. It employs single cavity plunger type of fixing filling volume technique. It is equipped with CO2 accuracy pressure control, so that the liquid level is always stable.

The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation etc.

The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation etc.

Washing part

Into bottle way is air conveyor direct connection with bottle dial.

All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean. 304/316

Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

304/316 stainless steel washing pump make the machine more durable.

All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean. 304/316

Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

304/316 stainless steel washing pump make the machine more durable.

Filling part

304/316 Stainless steel high precision filling nozzle Filling volume adjustable in fine rank, same liquid level after filling All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

304/316 stainless steel filling pump

Efficient spray nozzle rinse thoroughly and save water for flushing

304/316 stainless steel filling pump

Efficient spray nozzle rinse thoroughly and save water for flushing

Capping part

Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping All 304/316 stainless steel construction No bottle no capping

Automatic stop when lack of bottle

Capping effect is stable and reliable, Defective rate ≤0.2%

Automatic stop when lack of bottle

Capping effect is stable and reliable, Defective rate ≤0.2%

Main technical parameter

Model | DXGF 14-12-5 | DXGF 18-18-6 | DXGF 24-24-8 | DXGF 32-32-8 | DXGF 40-40-12 | DXGF 50-50-12 | |||||

Capacity (500ml) | 2000-3000 | 3000-5000 | 5000-7000 | 8000-9000 | 10000-12000 | 12000-14000 | |||||

Suitable bottle shapes | PET circular | ||||||||||

Bottle diameter | 50-115mm | ||||||||||

Bottle height | 160-320mm | ||||||||||

Filling type | Isobaric filling | ||||||||||

Filling pressure | <0.4MPa | ||||||||||

Rinsing water pressure | >0.06MPa <0.2MPa | ||||||||||

Application | Carbonated soft drink bottling line | ||||||||||

Total power | 4.4kw | 5.2kw | 6.2kw | 7.5kw | 8.2kw | 11kw | |||||

Overall dimensions | 2.5*1.9m | 2.8*1.9m | 3.2*2.2m | 3.4*2.5m | 4.8*2.3m | 5.5*3.3m | |||||

Height | 2.3m | 2.5m | 2.5m | 2.5m | 2.5m | 2.5m | |||||

Weight | 3000kg | 4500kg | 6000kg | 8500kg | 10000kg | 11000kg | |||||

NAME | BRAND | AREA |

PLC | Siemens | Germany |

INVERTER | Siemens | Germany |

CONTACTOR | Siemens | Germany |

TOUCH SCREEN | Siemens | Germany |

INVERTER | Siemens | Germany |

MOTOR | ABB | SWISS |

PNEUMATIC PARTS | FESTO | GERMANY |

ELECTRICAL PARTS | SCHNEIDER | FRANCE |

Turnkey Solution

1.RO system

This RO system is very important in the whole water project, we prefer you supply water analysis report from your local inspection department. This RO system we can make to match up with your water filling machine from capacity from 500L/Hr to 50000L/hr.

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

This system included sand filter, carbon filter, sodium exchanger, precision filter, Reverse Osmosis, UV, Ozone generator, Ozonized Tower, Pure water tank. This system is made of SUS304 or SUS316 material, thickness is 2.5mm-3mm we promised.We use GNP or CNP water pump, USA DOW or HYDRANAUTICS membrane, etc

2.Automatic blow molding machine for PET bottle:

Full automatic blowing machine from 2 cavity, 4 cavity, 6 cavity, 8 cavity, 9 cavity, etc from 2500BPH to 12000BPH for 500ml bottle.

3.Carbonated drink mixer and water chiller

Carbonation mixer: 1500L/Hr,2000L/Hr,3000L/Hr,5000L/Hr, etc. Co2 content is from 2.0-3.8

Water chiller: working with carbonation mixer, the cooling medium of water chiller going to heat plate exchanger of carbonation mixer to cooling carbonation drink to 3 degree to 8 degree (filling temperature).

Water chiller: working with carbonation mixer, the cooling medium of water chiller going to heat plate exchanger of carbonation mixer to cooling carbonation drink to 3 degree to 8 degree (filling temperature).

4.Automatic OPP hot glue labeling machine:

Capacity: 100-350bottles/min can be chosen Label material: PVC PET OPS, etc

Bottle material: PET PE PP Glass Bottle Diameter: 28 ~ 120mm

Bottle Height: 15~320mm Bottle shape: round, square, ellipse, rectangular

Label length: 30~250mm(max) Label thickness: 0.03~0.13mm

Bottle material: PET PE PP Glass Bottle Diameter: 28 ~ 120mm

Bottle Height: 15~320mm Bottle shape: round, square, ellipse, rectangular

Label length: 30~250mm(max) Label thickness: 0.03~0.13mm

Recommend Products

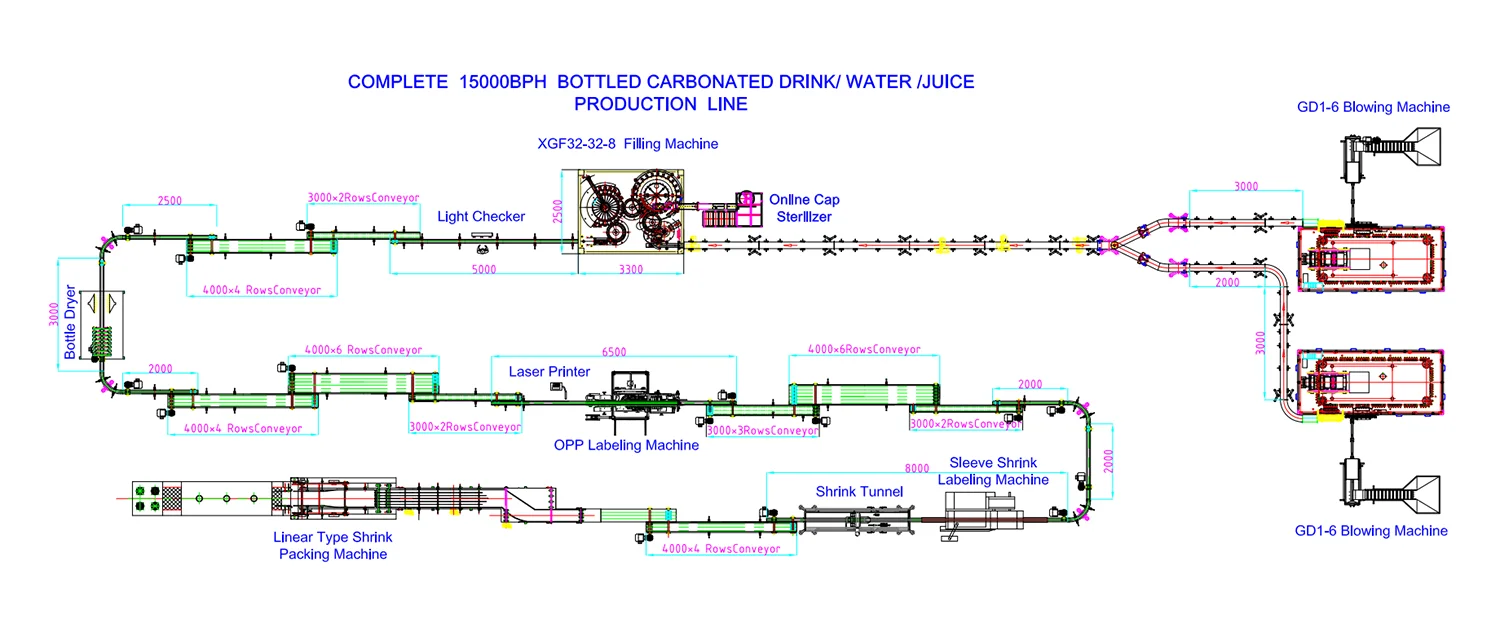

Turkey Project - Carbonated Drink/Water/Juice Production Line

High Speed PE Film Shrink Packing Machine

Packing speed: 22-28bags/min

Automatic Sleeve Shrink Labeling Machine

1. signle head or double heads available

2. Output: 150-350bottles/min

2. Output: 150-350bottles/min

Automatic PE Film Shrink Packing Machine

Speed: 8-10bags/min

Company Profile

GRANDEE MACHINE is located in Zhangjiagang City, near Shanghai China. We are expert in the field of liquid packaging machinery in the world. We have more than 10,000 square meters standard workshop, providing customers with a variety of product development, engineering design, consulting, technical services and other integrated EPC solutions.

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line , can filling and sealing line, complete blowing labeling and packaging system.

We are a technology-leading company, have a superior technology and talent team in liquid packaging machinery, electrical, computer engineering, etc. Our main products are blowing filling capping Combiblock, Aseptic cold filling machine, water treatment equipment, drinking water filling machine, juice and carbonated drink production line , can filling and sealing line, complete blowing labeling and packaging system.

We have a professional pre-sales support and good after-sales service team. They are good at communicating, expressing, and understanding customer’s needs. The average working experience is more than 10 years. They have rich experience for installation and debugging, and provide thoughtful services and solutions.

We have laser cutting, CNC machining centers, and other various processing equipment to provide customers with precise and reliable products. The ERP system provides an important resource integration path for production management and ensures production and delivery cycles.

FAQ

Q1: How to find suitable machine or complete beverage production line?

A1: Looking for beverage filling machine in www.grandeemachine.en.alibaba.com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for.

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team , providing good and after-sales service term , professional salesman terms .

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee , and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

A1: Looking for beverage filling machine in www.grandeemachine.en.alibaba.com

•Enquiry: Contact us by email, phone call, fax, Instant Messenger (Trade manager, Skype, WhatsApp, Wechat) and let us know your requirements

• Discussion: Specify the items and what are you exactly looking for.

Q2: Are you a trading company or a manufactory?

A2: We are the manufacture of water/beverage filling machine and water treatment system over 10 years. We just not only sell drinking water machines and other related equipment, Quality is our culture. We have rich experienced engineers with technicians working team , providing good and after-sales service term , professional salesman terms .

Q3: Do you have technical support after we purchased your machines?

A3: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q4: If you buy our machines, can you offer us wear-out spare parts?

A4: We provide our high quality machine 2 years guarantee , and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

For more information, please feel free to contact us to send inquiries!