LK106MF-BS полностью автоматическое штанцевание и загибочный станок с

- Категории: Paper Production Machinery >>>

- Поставщик: Wenzhou,Guangya,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

*Easy to deal with mass production continuously.

*Quick-lock version frame device, shorten the debugging time by 50%.

*With center alignment function from conveying to die cutting.

*Automatic pressure adjustment system by servo motor, higher precision and more convenient.

*Automatically decrease pressure if no paper, extend mould service life.

*Non-stop sampling function, improve work efficiency.

Model | LK106MF-BS |

Max. sheet size | 760×1060mm |

Min. sheet size | 350×400mm |

Max.die cutting speed | 7800s/h |

Max. working pressure | 2.6MN |

Gripper margin | 9-17mm |

Max. die cutting size | 746×1060mm |

Max. relief format | 730×1060mm |

Specification of cutting height | 23.8mm |

Max.delivery pile height | 1300mm(with pallet) |

Max.feeding pile height | 1500mm(with pallet) |

Max.feeding pile height(Non-stop model ) | 1200mm(with pallet) |

Main motor power | 15kw |

Total Machine power | 20kw |

Air requirements | 0.6Mpa,>0.37m³/min |

Machine weight | 21T |

Overall machine dimensions(without pedals) | 6635×2250×2345mm |

Overall machine dimensions(with pedals) | 6635×4152×2345mm |

Feeder

1. Side-to-side movement about paper feeding

2.Steady paper feeding system with blowing function

3.Pressure,feeder,paper delivery with smart one-click completion function

4. Feeder protective device in case of crashing

5. the suction cups are adjustable according to the paper deformation in a lateral way

6. Safety system for lowering the pile tray

Feed table

1.Automatic adjustment of brush and rollers

2.The belt would loosen during using, and the machine has the function of automatically adjust and tighten the belt.

3.Covered with an anti-static stainless steel plate

4. Double sheet detector

3. Support plates at the entry of platen station

4. Sheet hold-down device (guiding the sheets to the front lays)

5. Upper frame with manual lifting device

6. Wide conveyor belts ensure sheets accurately to the front and side lay units

2.The Gripper bar adjustment mechanism ensures the high precision of mechanical operation.

3.The chain which is imported from Germany which is favorable with high stability, high service life and other features.

Main Machine

1.Air actuated clutch Imported from Italy. It is Safe and convenient

2.The system detects whether there is paper inside the motor and automatically loads and unloads under pressure.

3. Gripper reopening device

4. Gripper fine adjustment

5. Automatic "on and off" pressure device of the platen.

6. Equipment centering and locking.

7. Automatic locking of the chase against the upper beam

8. Measurement of the cutting force with strain gauge automatically

Delivery

1. Pile tray

2. Pneumatically controlled pivoting front joggers

3. Adjustable rear and side joggers with centerline marks

4. Braking Brush

5. Manual non-stop rack

6.Brush automatic pressure adjustment function

7.Automatic non-stop paper collection function

The delivery section can adjust the speed and blow the paper down.

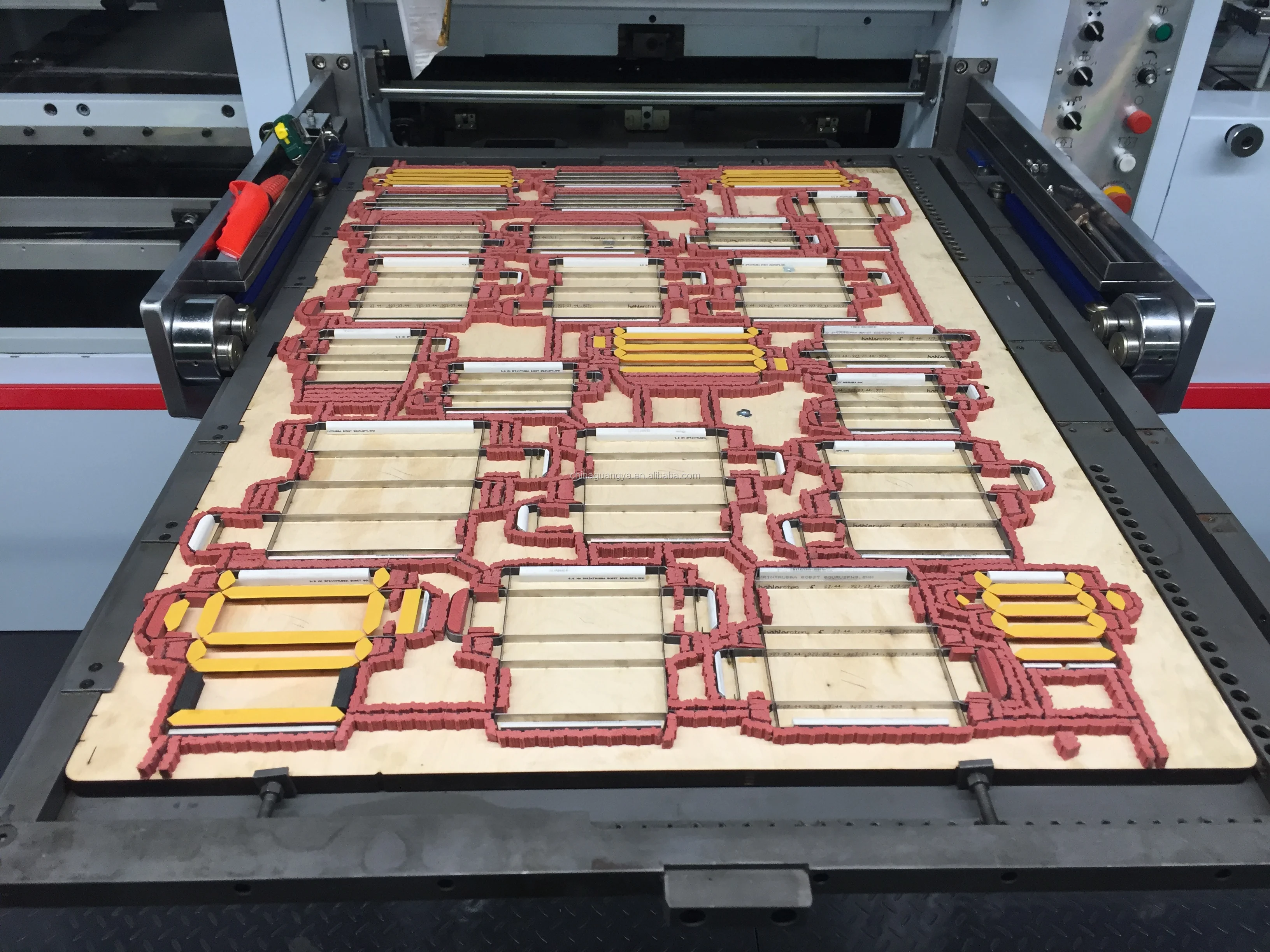

Stripping Section

1. The stripping frame adopts upper, middle, lower structure

2. The stripping needle and male-female plate are available.

3. The stripping frame is equipped with centralized positioning and quick-lock system

4. The upper stripping frame was controlled by the motor

5.With secondary stripping window

* Testing support in our factory

* Inspect machine in our Factory

* Engineers available to service machinery overseas