200/300/350TPD никелевая рудная Вращающаяся печь для минеральных продуктов обжига железной

- Категории: >>>

- Поставщик: Henan,Hongke,Heavy,Machinery,Co.,Ltd.Henan,Ltd.

Поделиться:

Описание и отзывы

Характеристики

200/300/350TPD Nickel Ore Rotary Kiln for Mineral Products Rotary Kiln Iron Ore Reduction Furnace Manufacturer

Product Overview

Rotary Kiln Reduction Furnace is simple in structure. It is a "great master" in the reduction iron process.

The production process is easy to control, less vulnerable parts and high operation rate. It is a equipment for calcining high standard iron ore in machinery plant,and is also widely used in metallurgical, chemical and construction industries.

The reduction iron rotary kiln produced by our factory is sturdy, smooth running.High quantity, it is one of the good equipment for investment..

The reduction iron rotary kiln produced by our factory is sturdy, smooth running.High quantity, it is one of the good equipment for investment..

PROCESS PROCESS

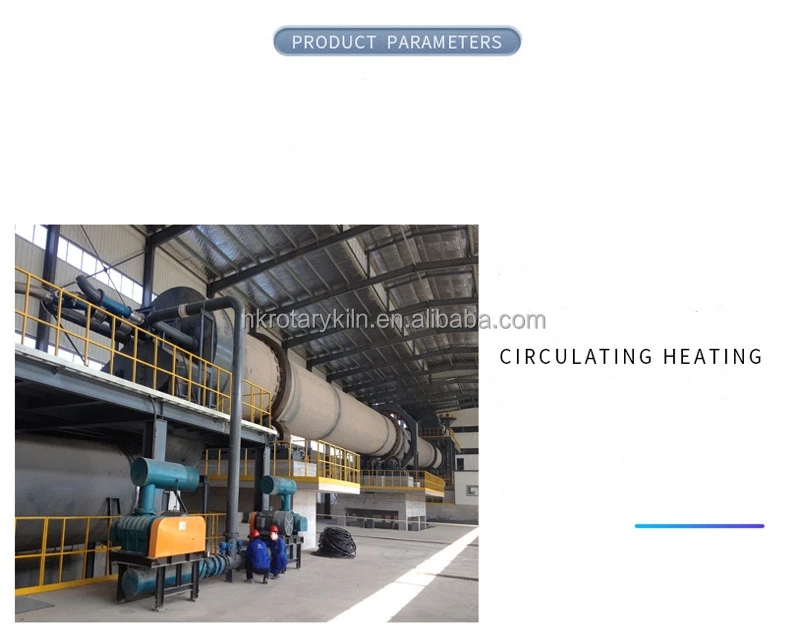

1. The structure of Rotary Kiln Reduction Furnace is advanced. The preheater with low pressure loss in our company can effectively improve the preheating effect. After preheating, the decomposition rate of raw material into kiln can reach 30%.

2. Iron kiln rotary furnace can be calcined in rotary kilns with different degrees of fine particles.

3. Reliable combined scale seal is adopted in the rotary kiln of reductive iron, so that the air leakage coefficient is less than

100.The compound refractory is used to reduce the radiation heat loss.

4. The equipment adopts a square vertical cooler with filling type and district ventilation. The calcareous temperature of the outlet cooler is above 65 °C, which is convenient for transportation and storage, and can preheat the secondary air in the kiln to more than 700 °C, which is helpful for the full combustion of fuel.

5 . The rotary kiln system of reduced iron adopts micro - negative pressure operation, and the production environment is clean environment- friendly.

3. Reliable combined scale seal is adopted in the rotary kiln of reductive iron, so that the air leakage coefficient is less than

100.The compound refractory is used to reduce the radiation heat loss.

4. The equipment adopts a square vertical cooler with filling type and district ventilation. The calcareous temperature of the outlet cooler is above 65 °C, which is convenient for transportation and storage, and can preheat the secondary air in the kiln to more than 700 °C, which is helpful for the full combustion of fuel.

5 . The rotary kiln system of reduced iron adopts micro - negative pressure operation, and the production environment is clean environment- friendly.

PRODUCT SPECIFICATIONS

Specification Model (m) | The size of the kiln | Yield (t/h) | Speed (r/min) | Electrical power (kw) | Weight (t) | Remarks | ||||

Diameter (m) | Length (m) | Gradient (%) | ||||||||

φ1.4×33 | 1.4 | 33 | 3 | 0.9-1.3 | 0.39-3.96 | 18.5 | 47.5 | ---- | ||

φ1.6×36 | 1.6 | 36 | 4 | 1.2-1.9 | 0.26-2.63 | 22 | 52 | ---- | ||

φ1.8×45 | 1.8 | 45 | 4 | 1.9-2.4 | 0.16-1.62 | 30 | 78.2 | ---- | ||

φ1.9×39 | 1.9 | 39 | 4 | 1.65-3 | 0.29-2.93 | 30 | 77.59 | ---- | ||

φ2.0×40 | 2 | 40 | 3 | 2.5-4 | 0.23-2.26 | 37 | 119.1 | ---- | ||

φ2.2×45 | 2.2 | 45 | 3.5 | 3.4-5.4 | 0.21-2.44 | 45 | 128.3 | ---- | ||

φ2.5×40 | 2.5 | 40 | 3.5 | 9.0-10.5 | 0.44-2.44 | 55 | 149.61 | ---- | ||

φ2.5×50 | 2.5 | 50 | 3 | 6.25-7.4 | 0.62-1.86 | 55 | 187.37 | ---- | ||

φ2.5×54 | 2.5 | 54 | 3.5 | 6.9-8.5 | 0.48-1.45 | 55 | 196.29 | ---- | ||

φ2.7×42 | 2.7 | 42 | 3.5 | 10.0-11.0 | 0.10-1.52 | 55 | 198.5 | ---- | ||

φ2.8×44 | 2.8 | 44 | 3.5 | 12.5-13.5 | 0.437-2.18 | 55 | 201.58 | Preheater kiln | ||

φ3.0×45 | 3 | 45 | 3.5 | 12.8-14.5 | 0.5-2.47 | 75 | 210.94 | ---- | ||

φ3.0×48 | 3 | 48 | 3.5 | 25.6-29.3 | 0.6-3.48 | 100 | 237 | |||

φ3.0×60 | 3 | 60 | 3.5 | 12.3-14.1 | 0.3-2 | 100 | 310 | ---- | ||

φ3.2×50 | 3.2 | 50 | 4 | 40.5-42 | 0.6-3 | 125 | 278 | |||

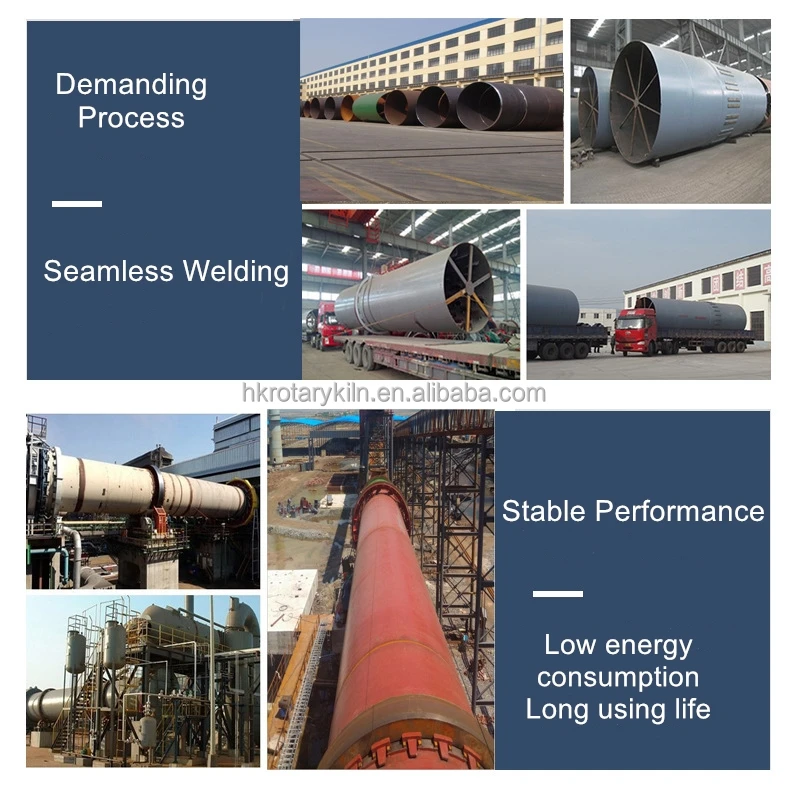

FEATURES AT A GLANCE

The combustion temperature, combustion atmosphere and combustion time can be adjusted and controlled flexibly to better adapt to the technological requirements.

Rotary Kiln Reduction Furnace has the advantages of uniform heating of materials, full reaction, good product, good quality, stable and reliable operation of equipment, high adjustability and simple operation and maintenance.

Successful Project

Factory Workshop Pictures

COMPANY PROFILE

Henan Hongke Heavy Machinery Co., Ltd. is located in Henan Province which is the cultural base of the central area of China. We are a mining machinery manufacturing enterprise that integrates scientific research, production and marketing.

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

We are a high-tech enterprise that specializes in the research and production of rotary kilns, dryers, crushers and so on, such as new type of lime rotary kiln, ceramsite kiln, zinc oxide rotary kiln, sludge rotary kiln, chemical rotary kiln, metallurgical rotary kiln, Raymond mill, ultra-fine mill, large and medium dryer, ball mill, sand mill,stone production line, mineral processing equipment and so on.

From the design, production, installation and debugging, we provide you the entire tracking service.We adhere to the aim of high quality to survive, good credibility to make development, and sincerely look forward to cooperating with you!

FAQ

1. What is the minium order quantity?

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foudation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). Size and content analysis of raw material

2). Capacity ( t/h)

3). Heating Source ( Coal, natural gas or oil)

Upon we got your message we shall give you our favorable offer in short time.

One set.

2.How long is the warranty period?

One year. Wearing parts are excluded.

3. What is the after-service of your company?

We can provide the customers foudation drawing, installation service, work training as well as other service according to the

customer's requirements.

4.How long is the delivery time?

About 15 days after we receive the payment.

5. What are the payment terms?

T/T, L/C are the best, it can be adjustable according to different situations.

--------------------------------------------------------------------------------------

Kindly Note:

1. Please pay attention to the capacity. It's what you must take into consideration in choosing a suitable machine.

2. Please Inform us the follow figures:

1). Size and content analysis of raw material

2). Capacity ( t/h)

3). Heating Source ( Coal, natural gas or oil)

Upon we got your message we shall give you our favorable offer in short time.