Конусная дробилка Pyz1750 Pyd1750 одноцилиндровая

- Категории: >>>

- Поставщик: Shanghai,Zenith,Mineral,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

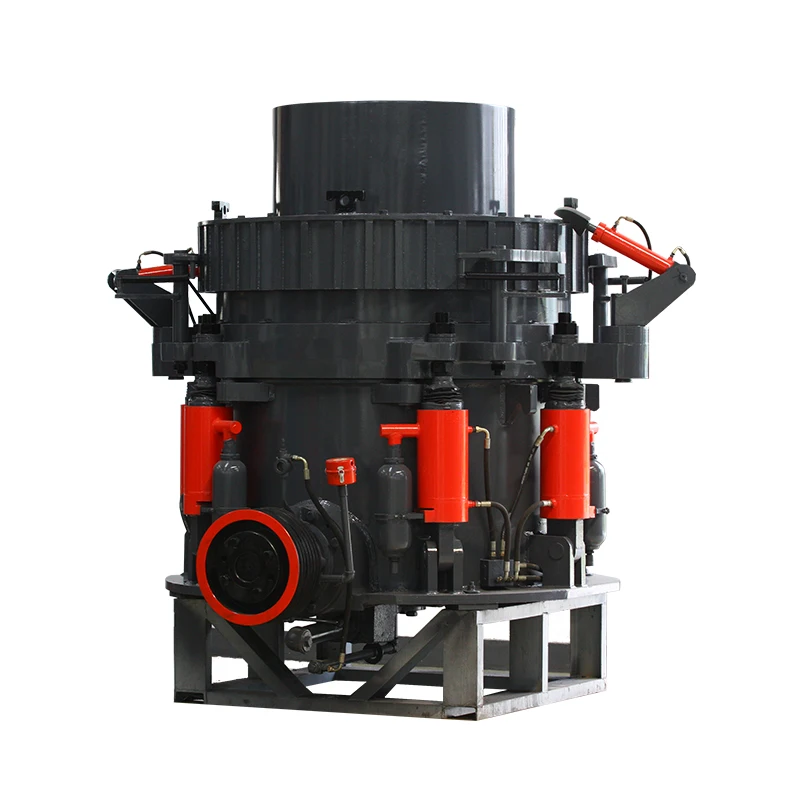

Mining Machine Pyz1750 Pyd1750 Cone Crusher Single Cylinder Cone Crusher

Based on some design principles of traditional multi-cylinder hydraulic single cylinder cone crusher like fixed main shaft, eccentric sleeve rotating around main shaft and lamination crushing, HPT HPTc gold ore cone crusher HPT 200 makes a breakthrough on its structure. After optimization, the structure improves the performance and crushing capability a lot. Meanwhile, the hydraulic lubrication system of HPTc gold ore cone crusher HPT 200 not only ensures the stable operation but also makes the system control more intelligent.

Product Features: Higher crushing ratio, bigger processing capacity, better granularity and shape of finished products

Input Size: 0-350mm

Capacity: 45-1200TPH

Material: Granite, diabase, basalt, pebble, limestone, dolomite, metallic ores and non-metallic ores, etc.

Mining Machine Pyz1750 Pyd1750 Cone Crusher Single Cylinder Cone Crusher working principle:

When a single cylinder cone crusher works, driven by the motor, the transmission shaft rotates under the action of belt pulley and triangular belt. Next, the transmission shaft drives the eccentric sleeve to make it rotate around the axis. Meanwhile, the eccentric sleeve forces the movable cone to do pendular movement. This movement makes the movable cone and fixed cone sometimes close to, sometimes far away from the rolling wall. Materials are continuously shocked, squeezed and crushed in the crushing cavity between the crushing wall and the rolling wall. Finally, materials are discharged out of the machine when their fineness reaches the discharging standard.

Mining Machine Pyz1750 Pyd1750 Cone Crusher Single Cylinder Cone Crusher album:

Mining Machine Pyz1750 Pyd1750 Cone Crusher Single Cylinder Cone Crusher parameters:

| Model | Cavities | Feed opening (mm) | Minimum discharging size (mm) | Capacities (t/h) | Nominal installed power (kw) | Maximum installed power (kw) | Overall dimension (mm) |

| HPT100 | C1(Extra Coarse) | 140 | 19 | 75-140 | 90 | 90 | 1705×1510×1583 |

| C2(Coarse) | 100 | 13 | 60-110 | ||||

| M(Medium) | 70 | 9 | 52-100 | ||||

| F1(Fine) | 50 | 9 | 50-95 | ||||

| F2(Extra Fine) | 20 | 6 | 45-90 | ||||

| HPT200 | C2(Coarse) | 185 | 19 | 145-250 | 160 | 160 | 2135×1750×1927 |

| M(Medium) | 125 | 16 | 135-235 | ||||

| F1(Fine) | 95 | 13 | 115-220 | ||||

| F2(Extra Fine) | 75 | 10 | 90-190 | ||||

| HPT300 | C1(Extra Coarse) | 230 | 25 | 220-440 | 220 | 250 | 2725×2110×2871 |

| C2(Coarse) | 210 | 19 | 190-380 | ||||

| M(Medium) | 150 | 16 | 175-320 | ||||

| F1(Fine) | 105 | 13 | 145-280 | ||||

| F2(Extra Fine) | 80 | 10 | 110-240 | ||||

| HPT400 | C1(Extra Coarse) | 295 | 30 | 300-630 | 315 | 315 | 2775×2370×2295 |

| C2(Coarse) | 251 | 25 | 285-560 | ||||

| M(Medium) | 196 | 20 | 250-490 | ||||

| F1(Fine) | 110 | 13 | 180-345 | ||||

| F2(Extra Fine) | 90 | 10 | 135-320 | ||||

| HPT500 | C1(Extra Coarse) | 330 | 38 | 425-790 | 400 | 400 | 2800×3480×4050 |

| C2(Coarse) | 290 | 30 | 370-700 | ||||

| M(Medium) | 210 | 22 | 330-605 | ||||

| F1(Fine) | 135 | 16 | 270-535 | ||||

| F2(Extra Fine) | 95 | 13 | 220-430 | ||||

| HPT800 | C1(Extra Coarse) | 350 | 38 | 570-1200 | 630 | 630 | 3970×3345×4235 |

| C2(Coarse) | 299 | 32 | 520-1050 | ||||

| M(Medium) | 265 | 25 | 475-950 | ||||

| F1(Fine) | 220 | 16 | 370-800 | ||||

| F2(Extra Fine) | 150 | 13 | 310-600 |

Note:

1.The bulk specific weight is calculated by 1.6t/m³. When the width of the feeding port is above

600mm, it is a large-scale machine while when the width ranges from 300 to 600mm, it is a

medium-sized machine.

2.Product pictures and parameters about models, data, performances and specifications on this

website are for reference only. There is a chance that ZENITH may make changes on

above-mentioned information. For specific messages, please refer to the real objects and user

manuals. Without special instructions, ZENITH keeps the right to explain all data involved in

this website.

A VARIETY OF TRUSTED EXPERIENCE ZENITH has a variety of professional, reliable and efficient crushing lines all around the world. So customers have great confidence in us. |

INFINITE BRAND VALUE What ZENITH is doing is customizing economical and suitable production lines for customers and building brand value. |

1200,000 SQUARE METERS OF PRODUCITION AREA 6 large-scale manufacturing bases occupy 1200,000 square meters in total. So quick delivery is a matter of course. |

Shanghai Zenith Mineral Co., Ltd. is a hi-tech, engineering group. We are specialized in the research, development, and production of industrial crushing, powder grinding, mineral processing equipments and other related devices. Our products have been sold to 120 countries and areas of Southeast Asia, East Europe, South America, the Middle East and Africa etc, and more foreign markets will be promoted in future.

Zenith Factory

Headquarter of Zenith is located in Shanghai, China and now we have two manufacturing bases as our strong support. One is located in Shanghai about 450,000 square meters, and the other is in Qidong city, about 600,000 square meters. It takes about one-hour driving from Shanghai to Qidong city.

Exhibition

Zenith participate in various exhibitions frequently,such as Bauma China,China Import and Export Fair , Asia-pacific's International Mining Exhibition, Bauma Africa, CONEXPO Latin America , etc.

Zenith products have acquired :

Russian GOST Certificate

EU CE Cetificate

ISO Quality Management Certificate

China Good Enterprises

China Credit Example Certificate , etc.

If you are interested with our products, please don't hesitate to contact us now!

You can tell me the following questions, Then I can send you accurate quotation, including additional discount!

1. Which machine do you need?

2. what is your raw material plan to process?

3. The capacity you need

4. Your contact information

Now,please click the following contact to send us email or chat online!