Медная алюминиевая проволока с флюсовой сердцевиной

- Категории: >>>

- Поставщик: Qingdao,Tensileweld,Welding,Consumables,Co.,Ltd.Qingdao,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Low-temperature aluminum flux-cored welding wire can weld almost all white metals, including aluminum, aluminum alloy, aluminum-magnesium alloy and dissimilar welding between the above metals, even for white metals that have been severely corroded or polluted by oil, and even aluminum that is considered irreparable. All alloys can be repaired. Suitable for all-round welding by primary welding operators, only a small heating device is needed. The strength of the weld after welding is generally higher than the strength of the base metal itself, and it is enough to know the gas welding operation.

Instructions for use of low temperature aluminum welding wire

Instructions for use of low temperature aluminum welding wire

Don't need extra flux when welding, because this wire contain flux

Step 2: Heat the surface of the base material at the welding place until the temperature reaches the working temperature, so that the welding wire can be melted by the heat conduction of the base material to form a weld. When the surface temperature of the material is sufficient, the welding wire can flow and penetrate into the metal capillary well.

Step 3: When repairing thinner aluminum, just heat the aluminum base material to a suitable working temperature, and then use the welding wire to friction and fuse to form a weld. Only use a metal brush to melt the welding wire to fill the weld to form a weld.

Step 4: Small parts are welded with propane gas, and large parts are heated and welded with industrial gas or induction heating device. After welding, let it naturally slow down.

Instructions for use of low temperature aluminum flux cored welding wire

Step 1: physical cleaning, polishing the surface.

Step 1: physical cleaning, polishing the surface.

Step 2: Heat the surface of the base material at the welding place until the temperature reaches the working temperature, so that the welding wire can be melted by the heat conduction of the base material to form a weld. When the surface temperature of the material is sufficient, the welding wire can flow and penetrate into the metal capillary well.

Step 3: When repairing thinner aluminum, just heat the aluminum base material to a suitable working temperature, and then use the welding wire to friction and fuse to form a weld. Only use a metal brush to melt the welding wire to fill the weld to form a weld.

Step 4: Small parts are welded with propane gas, and large parts are heated and welded with industrial gas or induction heating device. After welding, let it naturally slow down.

PRODUCT SPECIFICATION | ||||||

Product Model | Diameter | Package | Weight (g) | |||

500mm*1.6mm | 1.6mm | 10/20/50/100pcs | 25/50/125/250g | |||

500mm*2.0mm | 2.0mm | 10/20/50/100pcs | 40/80/200/400g | |||

Chemical Composition of Deposited Metal(%)

Fe | Mn | Si | Zn | Ti | Cr | Al | Mg | Cu | Be |

0.18 | 0.10 | 11.95 | 0.17 | __ | __ | others | 0.09 | 0.22 | 0.003 |

Details Images

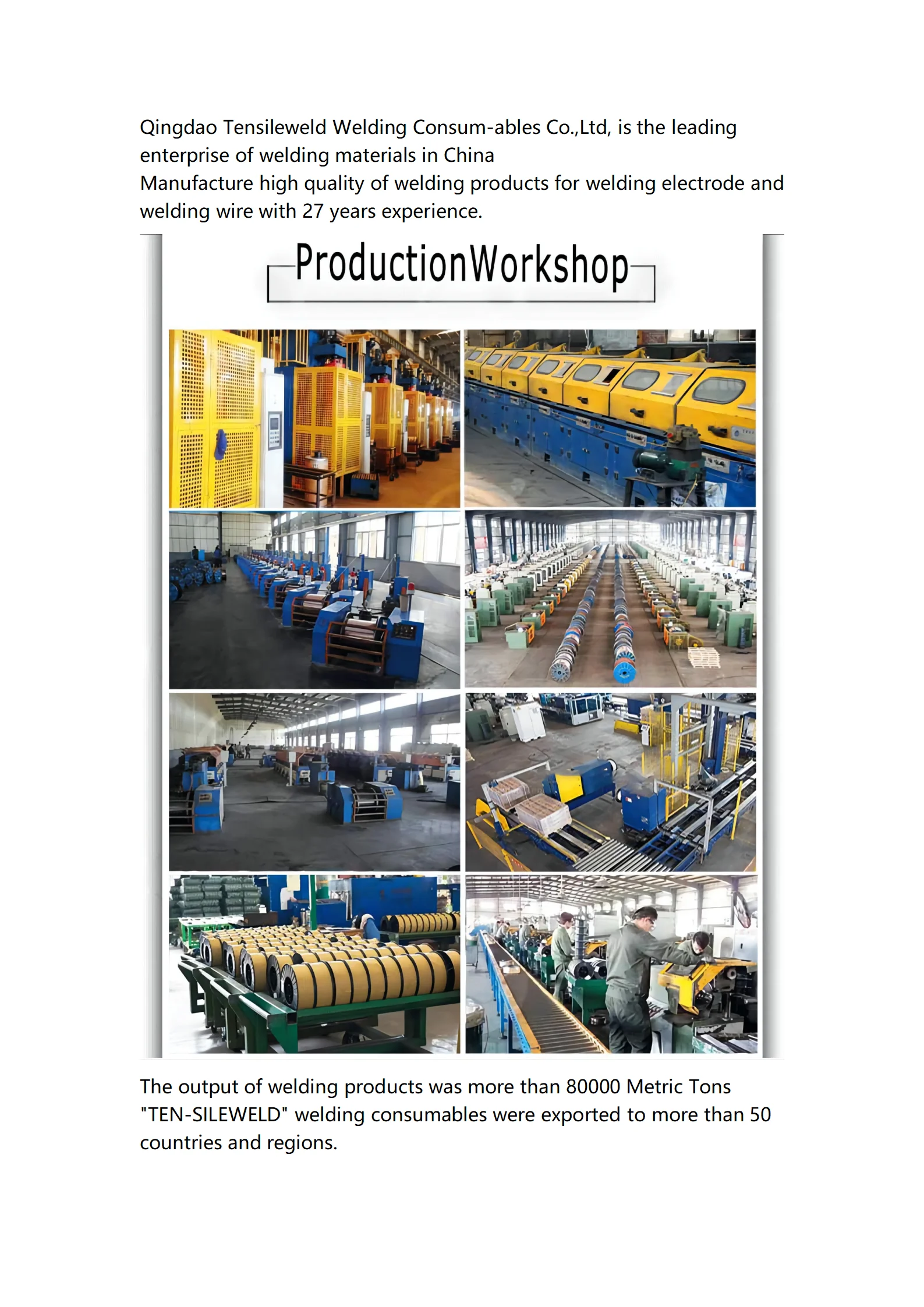

Our Factory

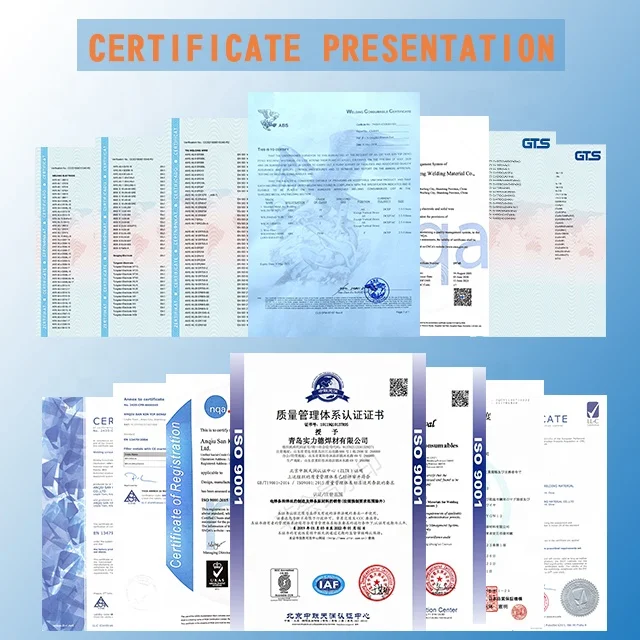

Certification

Our factory manufactures aluminum, aluminum alloy welding wires with our brand “Tensileweld”, including TIG Rod, MIG wire of aluminum and aluminum alloy welding wire and stainless steel welding wire in addition. Due to excellent quality and stable performance of our products, we have not only successfully obtained ISO 9001 quality management system certificate, but also got the approval from the Classification Society of China(CCS), Deutsche Bahn AG(DB), Conformity with European(CE), American Bureau of Shipping(ABS) and American Welding Society(AWS).

Our Services & Strength

With Customers

Simultaneously, our products could be widely adopted in variety of industries, such as petrochemical industry, pressure vessel, shipbuilding, vehicle, bicycle and aluminum formwork etc., which are not only deeply favored by amounts of domestic customers but also by the customers from USA, UK, Italy, Poland, Spain, Czech, Russia, Argentina, Brazil, Mexico, South Africa and more than 40 countries and regions.

In conclusion, our company adheres to “Integrity, Innovation, Service” as our business philosophy and “Better Brand, Better Reputation” as marketing concept, which commits to provide high quality products and better service to domestic and overseas customers.

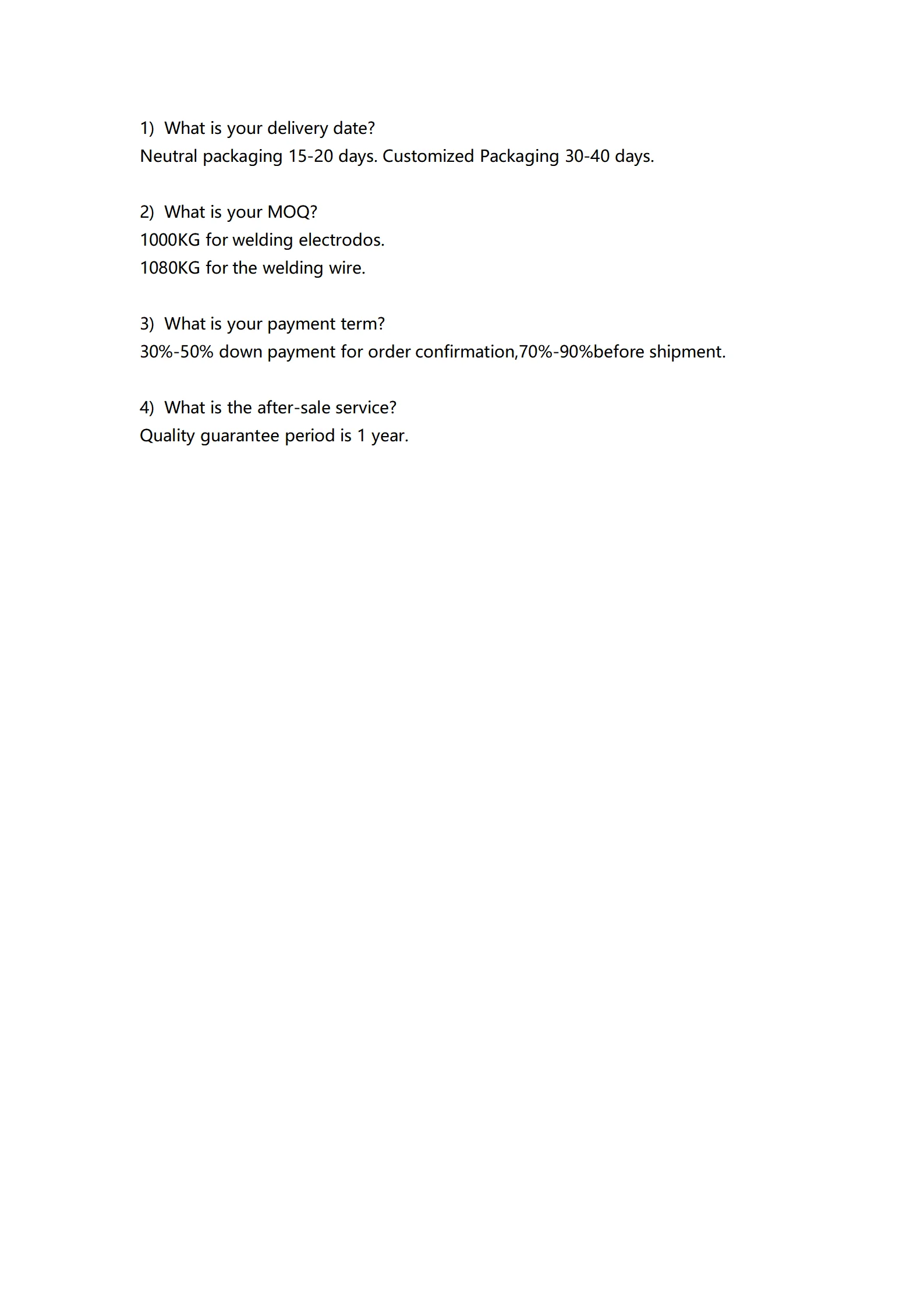

FAQ