Машина для очистки отшелушивания

- Категории: Other Farm Machines >>>

- Поставщик: Kaifeng,Hyde,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

petkus type trieur cylinder wheat cleaning machine grain processing machine

Hyde Machinery (Maosheng Group)

- Seed processing plant: 1~15 t/h

- Flour mill plant: 40~1000 t/d

- Manufacturer since 1976

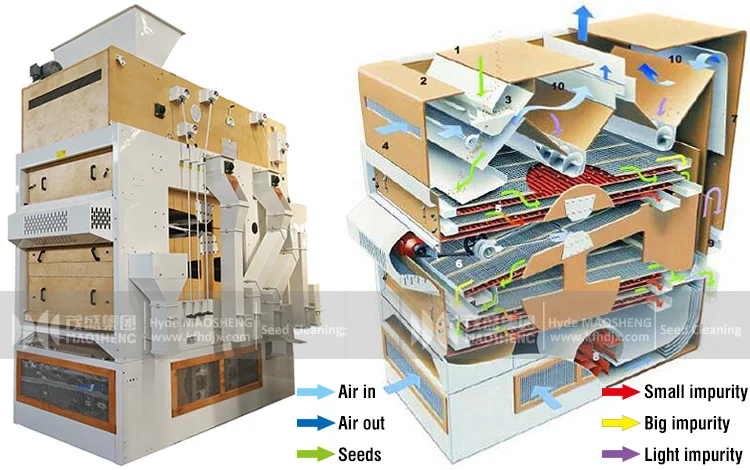

5X Air Screen Cleaner Fine Cleaning

1) Function: fine cleaning to remove impurities, broken and abortive grains; grading seeds according to sizes.

2) Application: cereal grains and seeds.

3) Capacity: up to 12t/h (wheat).

5X air screen seed cleaner has been developed specially for flexible, high quality cleaning for grains and seeds. It can be used for pre-cleaning and intensive cleaning, but mainly for seed cleaning.

Working Principle of 5X Air Screen Cleaner

Seeds and grains can be separated from impurities for different physical and mechanical properties.

Separation is completed by:

1. Fans (air blowers): by different weight and aerodynamic characteristics.

2. Screens: according to different width and thickness sizes of seeds.

Excellent cleaning and grading function is accomplished by variable screen configuration, pre and after suction system, and air lifting blowers at the bottom. Closed, bolted and painted steel construction ensures the long service life and safe operation.

Application of 5X Super Fine Seed Cleaner

5X air screen cleaners are widely used for cleaning of grains and seeds, such as wheat, barley, lentils beans, rice, maize, spices, grass seeds and forestry seeds.

The multi-layer cleaning screens are changeable easily for different processing requirements.

5X Air Screen Fine Cleaner in Seed Cleaning Plants (maize, wheat, paddy, etc)

Advantages of 5X Air Screen Cleaner

1) Multi-layer screens are installed in opposite directions, products discharge at lowest layer, good cleaning for large and small impurities.

2) Upper and lower screen boats are installed in opposite directions, good dynamical balance for stable running.

3) Easy interchangeable screens are flexible for different processing requirements.

4) Positive and negative pressure blower systems are installed at top or external and bottom, twice remove light impurities and diseased seeds.

5) Screen frames, light impurity settling chamber and feeder parts are made of high quality wood, good sealing and vibration absorption performance, whole machine running with low noise.

6) Wide adjustable range and easy adjustment realize fine cleaning process easily.

7) Integral steel frame rubber ball tray for screen cleaning, easy to clean the sieve and machine.

8) Safety guard is equipped for every moving part to ensure safe operation.

9) Box-type screen body structure efficiently reduce dust content in workshop.

10) Symmetric machine structure, products discharge system can be installed left or right according to site conditions of customer.

Technical Specification

| Model | 5X-5 | 5X-12 |

| Overall Dimension (L×W×H) | 3200×1920×3600 mm | 3790×1940×4060 mm |

| Total Weight | 3250kg | 3600kg |

| Rated Capacity (wheat) | 5t/h | 10-12t/h |

| Total Air Inflow | 8200m3 | 12520m3 |

| Power | ||

| Top Air Blower (Optional) | 4-72N0-5A,7.5kW | 4-79N0-6A,11Kw |

| Sieve Vibration Motor | 2.2kW | Y132S-8, 2.2 kW |

| Bottom Lifting System Motor (VVVF Motor) | 3.0kW | 3.0 kW |

| Feeding Motor (VVVF Motor) | 1.5kW | WR41-Y0.75-4P-1.68-M1, 1.5kW |

| Total Power | 6.7kW | 6.7kW |

| Sceen | ||

| Screen Type | Pierced Screen | |

| Screen Dimension (L×W) | 800×1250 mm | |

| Frequency | 300(80~400) /min | |

| Amplitude | 30 mm | |

| Layers and Number | 4 layers, 7 pieces | 5 layers,15 pieces |

| 1st layer | 1 piece, round hole | 3 pieces, slot hole |

| 2nd layer | 2 pieces, slot hole | 3 pieces, slot hole |

| 3rd layer | 2 pieces, slot hole | 3 pieces, slot hole |

| 4th layer | 2 pieces, slot hole | 3 pieces, slot hole |

| 5th layer | / | |

CONTACT

Notes:

1. Individual machine will be supplied with 1 set of screens (7 pcs or 15 pcs), no top blower.

2. Machine can be converted to different cleaning programs, screens shall be changed accordingly.

3. Above technical data can vary due to continued development, or different machine configurations.

Our main products are:

- Seed cleaning machines

Pre-cleaners, fine cleaners, rotary cleaners, seed graders, seed gravity separators, indented cylinder, wheat paddy de-awner, destoner, vibration cleaner, rotary cleaner, air aspirator, cyclone dust collector, seed treater, seed dryers, elevators and conveyors, auto-packing scales.

- Flour mill complete plants: 40~1000 t/d.

- Dryer and grain handling

Seed cleaning machines:

Air Screen Fine Cleaner Seed Gravity Separator Indented Cylinder Separator

Stone Separator Vibration Screen Cleaner Separator Rotary Cleaner

Kaifeng Hyde Machinery is a branch company of Henan Maosheng Group, which is formerly known as Kaifeng 2nd Grain and Oil Machinery and has specialized in engineering and equipment manufacturing for grain handling, storage, flour milling and seed processing since 1976.

With 40 years' growth, Maosheng Group company has become one of CHINA TOP 10 Grain Processing Machinery Manufacturer. In addition, Maosheng is the host of CHINA National Grain Processing Technology Research Center.

Kaifeng Hyde Machinery, separated in 2000 as a branch company, mainly manufactures a full range of advanced grain and seed processing machines.

Seed Processing Machines from Hyde Machinery

Cooperation of Maosheng Group Hyde Machinery

To better serve our clients, Maosheng Group not only imports high-end manufacturing facility to improve product quality and manufacturing productivity, but also keeps on looking for international communication and cooperation. We successfully signed agreement with Italy for machine development in 2009 and established joint venture with WESTRUP Denmark in 2013 and NoroGard Sweden in 2016.

Our partners and clients in China:

Honors of Maosheng Group Hyde Machinery

With decades of our effort, our machines have obtained China Top 10, China Famous Brand and enjoyed high reputation in domestic and oversea markets.

Member of 13 China national standards DRAFTER in grain industry. 75 patents including 4 inventions (till 2017).

Why choose us?

40 YEARS manufacturing experience since 1976.

CHINA TOP 10 Grain Processing Machinery Manufacturing Company.

Member of 13 China national standards DRAFTER in grain processing industry.

75 PATENTED technologies and products.

600,000 square meter production area.

Over 100 experienced engineers, research staff and technicians.

State-of-the-art facilities. Advanced imported CNC machines for function parts.

Full range of service, from single machine to turnkey systems in grain and flour industry.

Machinery and equipment quality tested by domestic and global market, rich installation and trouble-shooting experience.

State Leaders Visits to Maosheng Group, confirming our effort in grain processing industry

Pre-sales Service

1. Technical Consulting Service

Our wide product range enables us to provide most flexible, efficient and reliable equipment configurations or complete solutions for customers according to different requests and budgets.

2. Company and Production Line Visit

Before placing orders, customers are warmly welcome to visit Hyde and our facility. We can also arrange the visit to our existing customers to learn the operation condition of our machines and complete plant.

In-sales Service

1. Reliable delivery time.

2. Strict quality control by in-production 100% check and test.

3. User manual and spare parts provided for free.

After-sales Service

1. Fast technical guidance for construction, installation and commissioning.

2. Necessary training for daily maintenance on site.

3. 12 months warranty.

4. Lifelong regular technical service.

5. Timely solutions to problems.

Q: What do you need to know for fast communication and quotation?

A: It would be highly appreciated if you can provide details of your processing material, capacity, motor power supply voltage and special brand needed, and other working conditions.

Q: What about the lead time?

A: 10~30 workdays, depending on the type of machine and parts availability.

Q: What is your payment terms?

A: T/T, L/C, Western Union, Cash accepted.

30% deposit with purchase order, 70% balance paid before shipment.

Q: How can you guarantee the quality?

A: Quality control by incoming material inspection, 100% in-production check and random check after packaging.

Spare parts and technical solutions provided timely for machine failure.

Q: Can we see your factor through video chat since the pandemic makes overseas visiting harder?

A: Yes,please feel free to make an video chat appointment with us, we are glad to show our factory to you!

Welcome your enquiry and visit about High Quality Indented Cylinder Seed Separator!

Check below information, or just fill in the form and click "Send".