ПЭНД пластиковая труба Стыковая машина гидравлическая ПЭ сварочный аппарат стыковая

- Категории: >>>

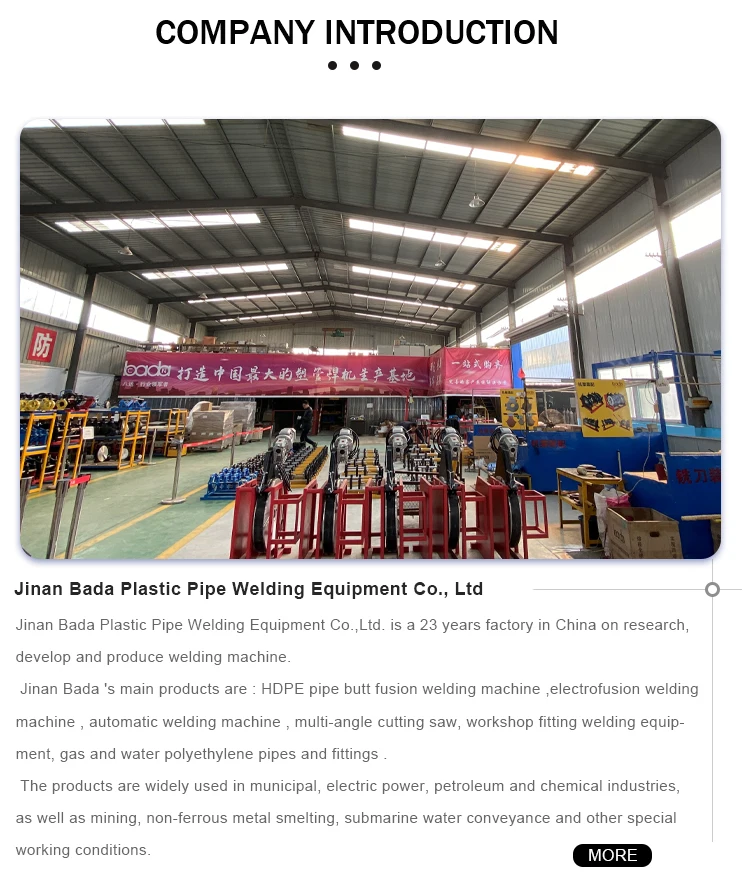

- Поставщик: Jinan,Bada,Plastic,Pipe,Welding,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Hot sale SHBD630 PE tube hot melt machine hydraulic butt fusion welding machine plastic pipe welding machine hot melt

1. The raw material of the machine frame is aluminum ZL104,it's light but strong,is one of the best material of the machine.

2. The main electrical parts elements are best of china,many are imported from abroads.

3 Removable PTFE coated heater with separate temperature control system,the temperature can be controlled to a minimum range

4. The cutter adopts powerful motor, special material of the blade, making the cutting effect more perfect

5. The machine with simple structure can be operated by one personit's suitable for use under complex conditions

FEATURES AT A GLANCE

1. Lower start-up pressure make the small diameter pipe welding more reliable.

2. Welding position can transform that it is

convenient for welding all kinds of pipe fittings

convenient for welding all kinds of pipe fittings

3. Stand alone dual channel timer can record both of heat and cooling hours,when time is over,the timer will give an alarm.

4. High precision shock proof pressure gauge with large dial is easy to read.

Model | SHBD630 | SHBD1000 |

Welding diameters (mm) | 630-400 | 710-1000 |

Heating plate temperature | 270°C | 270°C |

Heating plate surface temperature(170-250°C) | <±7°C | <± 10°C |

Pressure adjustment range | 0-6.3MPa | 0-12MPa |

Cross-sectional area of the cylinder | 2306mm2 | 2512mm2 |

Working Voltage | 380V, 50Hz | 380V, 50Hz |

Heating plate power | 9.2KW | 21.7KW |

Milling cutter power | 1.5KW | 3KW |

Hydraulic station power | 1.5KW | 3KW |

Lifter power | - | 1.1KW |

Total Power | 12.2KW | 28.8KW |

Gross weight | 1300kgs | 1300kgs |

Package size | 225*145*150 | 225*145*150 |

1. The raw material of the machine frame is aluminum ZL104, it is light but strong, is one of the best material for machine.

2. Lower start-up pressure make the small diameter pipe weld more reliable.

3. Welding position can transform that it is convenient for welding all kinds of pipe fittings.

2. Lower start-up pressure make the small diameter pipe weld more reliable.

3. Welding position can transform that it is convenient for welding all kinds of pipe fittings.

1. Timer, pressure gauge, temperature controller and alarm shall be installed on the operating table to facilitate observation and improve welding efficiency.

2. The temperature controller and pressure regulating valve are CE certified, and the control precision can reach 0.01%.

3. The hydraulic station is installed with an accumulator, which can realize the function of automatic pressure replenishment and reduce the number of manual pressure replenishment.

2. The temperature controller and pressure regulating valve are CE certified, and the control precision can reach 0.01%.

3. The hydraulic station is installed with an accumulator, which can realize the function of automatic pressure replenishment and reduce the number of manual pressure replenishment.

1. High power milling cutter, mirror cutter disk, strong motor, high concentricity, smooth milling.

2. High-power Bosch drill is adopted for milling motor, which is strong and strong without slipping

3. The milling cutter is equipped with a limited position switch, which can be rotated only when placed in the frame to prevent accidental injury.

2. High-power Bosch drill is adopted for milling motor, which is strong and strong without slipping

3. The milling cutter is equipped with a limited position switch, which can be rotated only when placed in the frame to prevent accidental injury.

1.Using Teflon coating material imported from Japan, after twice coating and three processes.

2.The solid core of the Heating plate is thickened and non-stick tube, the heat transfer is even, supporting the aviation

connection line to ensure the contact safety of the power supply.

3.Compared with other manufacturers, the thickness of Heating plate is increased by 5mm, and the heat storage and thermal conductivity are strong.

2.The solid core of the Heating plate is thickened and non-stick tube, the heat transfer is even, supporting the aviation

connection line to ensure the contact safety of the power supply.

3.Compared with other manufacturers, the thickness of Heating plate is increased by 5mm, and the heat storage and thermal conductivity are strong.

Successful Project

Project in Southeast Asia

Project in Southeast Asia

Project in Russia

Related Products

After Sales Service

1. One year warranty, life-long maintenance.

2. In warranty time, if non-artificial reason damaged can take old

change new for free. Out of warranty time, we can Offer maintenance service (charge for material cost).

3. Engineers available to service machinery overseas

2. In warranty time, if non-artificial reason damaged can take old

change new for free. Out of warranty time, we can Offer maintenance service (charge for material cost).

3. Engineers available to service machinery overseas

Company Introduction

Packing&Shipping

1.The shipping: 3 days after received payment

2.The packaging: standard export plywood cases

3:Our machine will be wraped by plastic film, put into a wooden box at last. This type of packages is avoid getting rusty easily.

2.The packaging: standard export plywood cases

3:Our machine will be wraped by plastic film, put into a wooden box at last. This type of packages is avoid getting rusty easily.

FAQ

1. What is your payment terms ?

100% TT in advance . Western Union , D/P, Credit card payment on line .

2. What’s your delivery time ?

3-5 days after payment

3.How about your Guarantee and Service ?

All designed according to ISO21307:2011(E), ISO12176-1 and DVS2207/1(08/2007)

International warranty: 12 months.

Any parts broken or does not work under normal operating, we are free to provide.

100% TT in advance . Western Union , D/P, Credit card payment on line .

2. What’s your delivery time ?

3-5 days after payment

3.How about your Guarantee and Service ?

All designed according to ISO21307:2011(E), ISO12176-1 and DVS2207/1(08/2007)

International warranty: 12 months.

Any parts broken or does not work under normal operating, we are free to provide.

Похожие товары

Аппарат для электросварки, 20-315 мм

US $945.00

Аппарат для электросварки

US $1075

SWT-V355/90 ч, 355 мм

US $3500