Горячая Распродажа от солнца воздушный Источник Evi Геотермальная Система нагреватель и охлаждение разделенный тепловой насос

- Категории: Heat Pump Water Heaters >>>

- Поставщик: Guangzhou,Mikee,New,Energy,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

Product Paramenters

Company Profile

Guangzhou Mikee New Energy Co., Ltd.

Guangzhou Mikee New Energy Co., Ltd. is a subsidiary of Sunrise Oriental Group (SH: 603366), a listed technology enterprise. Our factory is located in Shunde, Guangdong Province, covering an area of 69000 square meters, with a total investment of 75 million dollars. It is one of the best scale air energy production bases in Asia, and undertakes ODM and OEM of air energy and energy storage products.

We have a number of pre automated assembly lines for commercial and civil products, with an annual production capacity of more than 100W sets and an investment of 150W dollars to build the industry's top heat pump laboratory. We have core data in the fields of hot water dedicated compressors, aerospace level leakproof enamel liners, 3-minute intelligent defrosting technology, super class energy technology, microchannel fast heating technology, etc.

We have a number of pre automated assembly lines for commercial and civil products, with an annual production capacity of more than 100W sets and an investment of 150W dollars to build the industry's top heat pump laboratory. We have core data in the fields of hot water dedicated compressors, aerospace level leakproof enamel liners, 3-minute intelligent defrosting technology, super class energy technology, microchannel fast heating technology, etc.

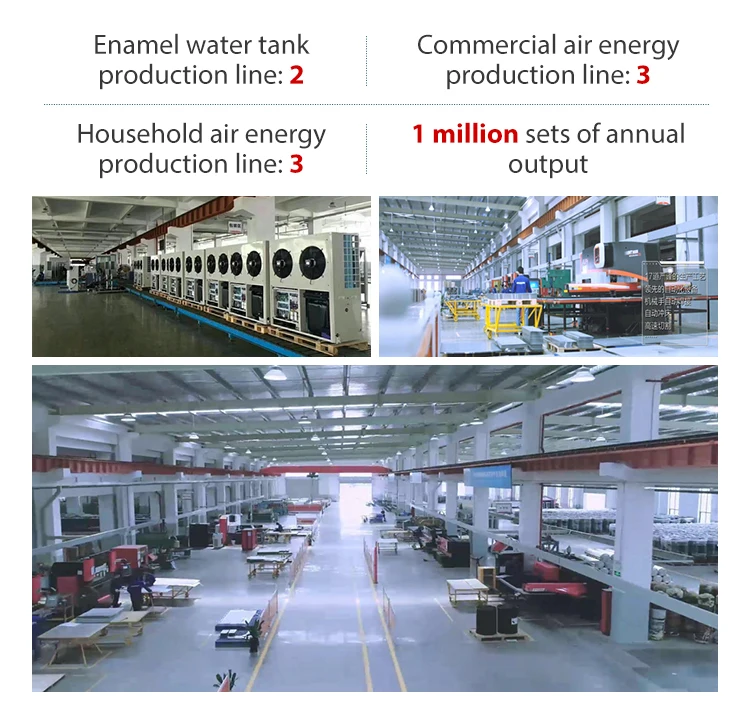

Our Advantages/Workshop

Commercial machine production line

▶▶ The commercial workshop has 3 production lines, 15 automated commodity inspection stations, which can be packaged and wound online. The maximum test capacity is 200P units, and 300 standard units can be produced in a single shift.

▶▶ The household workshop has two production lines, which can produce fluorine machines and water machines below 3P, 10 automatic vacuum pumping stations and 10 commodity inspection stations respectively. Robots are used for offline palletizing, and 700 standard units can be produced in a single shift.

▶▶ The household workshop has two production lines, which can produce fluorine machines and water machines below 3P, 10 automatic vacuum pumping stations and 10 commodity inspection stations respectively. Robots are used for offline palletizing, and 700 standard units can be produced in a single shift.

The sheet metal workshop has 3 laser cutting machines, 3 CNC punching machines, 6 CNC bending machines, 2 laser welding machines, and several equipment such as blanking and leveling, angle forming, spinning and pulling, plate shearing, deep throat punching, riveting, welding and grinding, with strong processing capacity.

The total length of the line is more than 520 meters, and the maximum workpiece can be sprayed 3 * 1.8 meters. The materials include galvanized plate, cold plate, brushed stainless steel plate, aluminum plate. The pre-treatment process includes degreasing and vitrification. QC inspection capabilities include: color detection, film thickness detection, hardness detection, adhesion detection, solvent resistance detection, ultraviolet aging test, impact resistance detection. The workpiece can be picked up and sent.

○ More than 10 million investment

○ Has ultra-low 60p temperature laboratory, enthalpy difference laboratory, data monitoring center, long-term operation laboratory

○ Ke - 30 ℃ environmental conditions

Certifications

Exhibition

Похожие товары

Тепловая система отопления для дома R32 R410a

US $1957-$2197

Удобный нагреватель для бассейна на природном газе

US $2850-$3400

H-180 мощный водонагреватель для бассейна 18 кВт

US $80.00-$110.00