Высококачественное оборудование для лазерной закалки машина обработки поверхности закалка лезвия формы

- Категории: >>>

- Поставщик: Dongguan,Sanhe,Laser,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

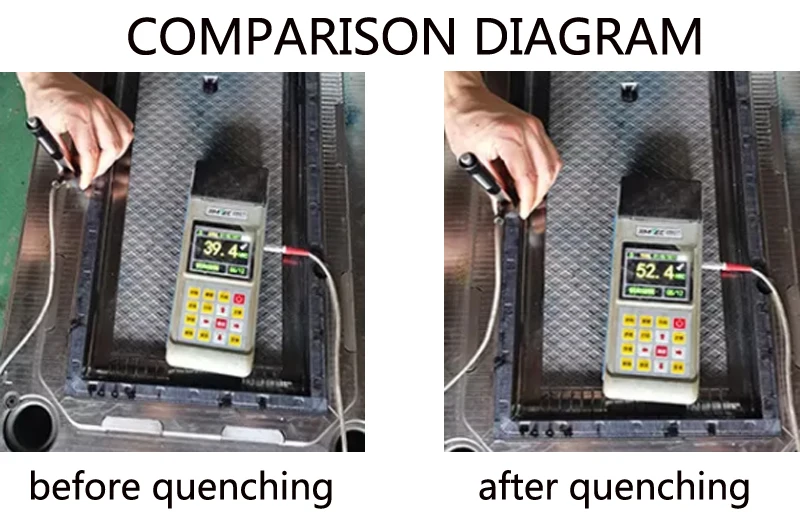

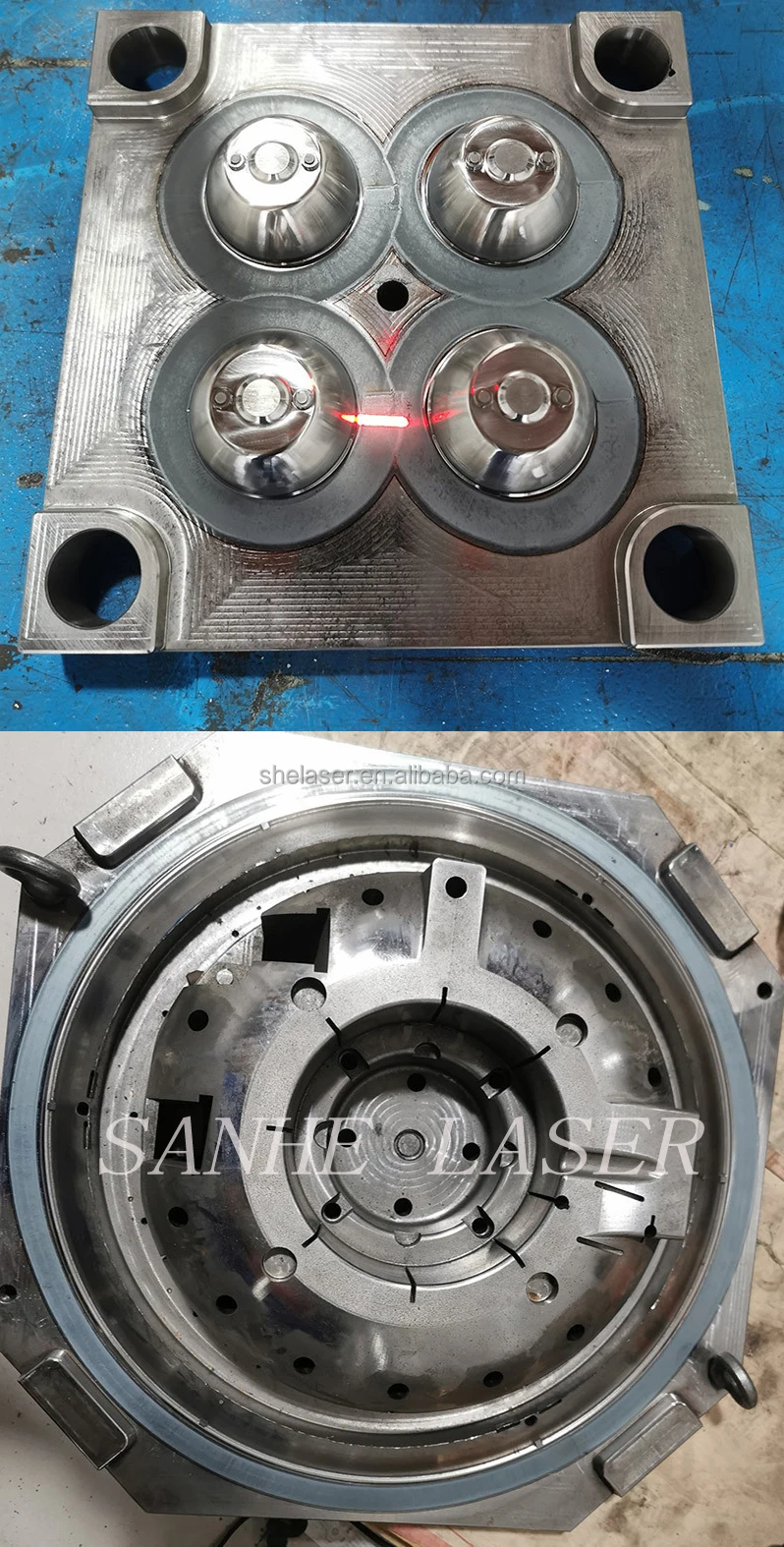

Laser quenching is a quenching technology that uses a laser to heat the surface of a material above the transformation point, and as the material cools itself, austenite transforms into martensite, thereby hardening the surface of the material.

The laser quenched tooth surface has a high heating and cooling rate, a short process cycle, and no external quenching medium. It has the advantages of small deformation of the workpiece, clean working environment, no need for finishing such as tooth grinding after treatment, and the size of the treated gear is not subject to heat treatment. Unique advantages such as device size limitations

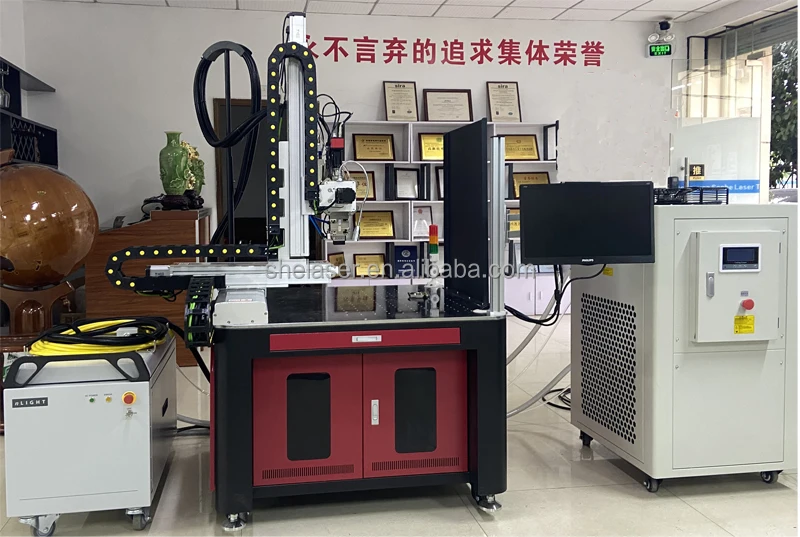

Model | RFL-A3000D |

Optical Parameters | |

Nominal Output Power (W) | 3000 |

Operation Modes | CW/Modulated |

Polarization Orientation | Random |

Output Power Tunability(%) | 10~100 |

Emission Wavelength(nm) | 915±10 |

Output Power Instability(%) | <3 |

Modulation Frequency(Hz) | 50~5k |

Pilot Light Power(mW) | 0.25~1 |

Output Cables Parameters | |

Output Header Type | QBH |

Fiber Core Diameter(μm) | 600 |

Minimum Bending Diameters | ≥400 |

Half Angle of beam divergence(rad) | ≤0.22 |

Delivery Cable Length(m) | 20(Customizable) |

Electrical Parameter | |

Power Supply | AC 380V±38, 50/60Hz, TN-S |

Control Mode | Hyper Terminal/RS-232/AD |

Other Parameters | |

Dimensions(W×H×D)(mm) | 650×950×980 |

Weight(kg) | <150 |

Operating Ambient Temperature (℃) | 10~40 |

Humidity (%) | <70 |

Storage Temperature (℃) | -10~60 |

Cooling Method | Water Cooling |

Power consumption | 22KW |

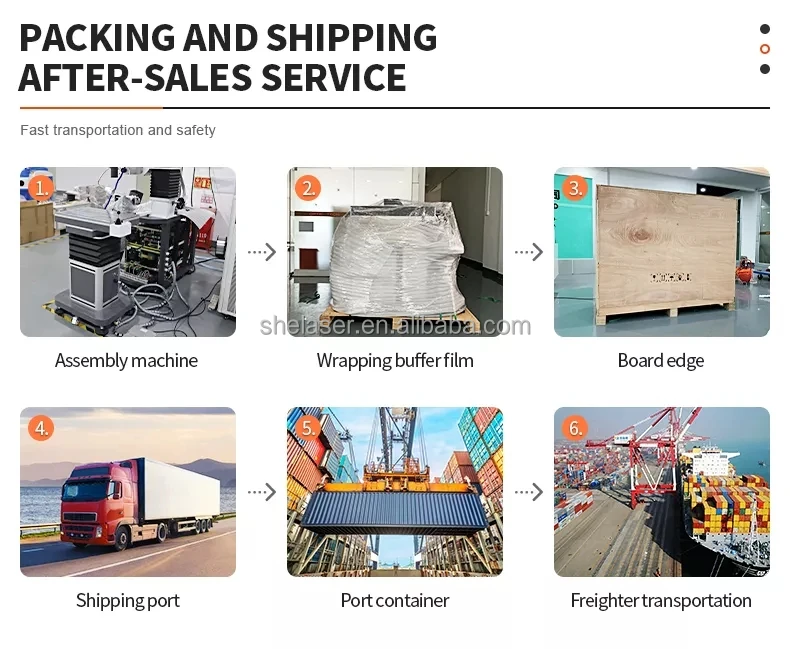

1) Free Pre-Sales Consulting / Free Sample Marking

2) Strict Quality Control of Production

3) 15-30 Days Quick Delivery

4) 1 Year Quality Guarantee

5) 12 hours Quick Feedback & After-Sales Service

6) Quick Back-up Parts Available & Technical Assistance

7) Free Training Service

8) Special Designing, Customized, OEM Order is accepted