2023 г. порошок из искусственного алмаза для резки

- Категории: Abrasives >>>

- Поставщик: Changsha,3,Better,Ultra-Hard,Materials,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Economic grade diamond micron powder:

Economic grade diamond micron powder:

1. Available sizes for economic grade diamond micron powder (um):

For Polishing : 0~0.5, 0~1, 0~2, 0.5~1, 0.5~1.5, 1~2, 1~3, 2~4, 2.5~5, 3~6

For Lapping : 4~8, 5~10, 6~12, 8~16, 10~20

For Grinding : 12~22, 20~30, 22~36, 36~54

2. Features of economic grade diamond micron powder

1. Strong abrasive resistance

2. High thermal stability and high impact resistance

3. blocky shape

4. low impurity(inner and outer)

5. Sharp cutting edges

6. High strength and self-sharpening

7. Higher toughness, high purity, processed by special milling and shaping techniques

3. Usages of economic grade diamond micron powder

1. Grinding and polishing of gems, optical objects and metals;

2. Suitable for using in precise wheels and saw blades;

3. Diamond micro powder can be processed to be PCD. PCD for mining, oil field, geological and cutting tools. Wire drawing dies, precise soft lapping plates and electroplate diamond wheels;

4. Suitable for using in loose form, compounds and slurries, or in resin bond tools and metal bond tools forgrinding, polishing, and lapping of cemented carbide, fine ceramics, variety of glasses, non-ferrous metals, precious and other hard materials;

5. It is also used to manufacture the abrasives like ceramic or electro plating. PDC, ceramics, stone and other workpieces grinding and polishing

6. Cutting, lapping, grinding and polishing on:silicon glass, optical glass, ceramic, and etc.

7. Resin bonded, vitrified bonded products and electroplated products; maching carbide, glass, ceramic, stone and other non-metallic materials.

| Name | synthetic diamond micro powder |

| Grit | Micro size : W0.1-W50 (used to surface polishing) Mesh size :30/35-500/600(used to kinds of diamond tools for cutting,drilling,grinding etc) |

| Advantage | 1.High grinding efficiency 2.Reasonable price & timely delivery 3.Including different kinds of grade for different request |

| usage | 1. resin bond abrasive or grinding, such as grinding wheel, soft grinding 2. the production of metal bonded abrasive, ceramic bonded abrasive or grinding, such as diamond grinding wheel, diamond saw blade, diamond drill 3. manufacturing geological drilling bit, semiconductor and non-metallic materials cutting and processing tools, such as drill bit composite sheet, stone cutting blade, etc. 4.stone, glass, gem cutting and polishing tools, such as diamond glass saw blade, plating saw blade, fish hook piece, diamond grinding wheel, soft film 5. used to produce stone, glass, precious stones, silicon crystal plates or other polishing products that require high-precision, brightness equipment. Such as polishing liquid 6. used to produce wire making tools, such as drawing die, drawing core |

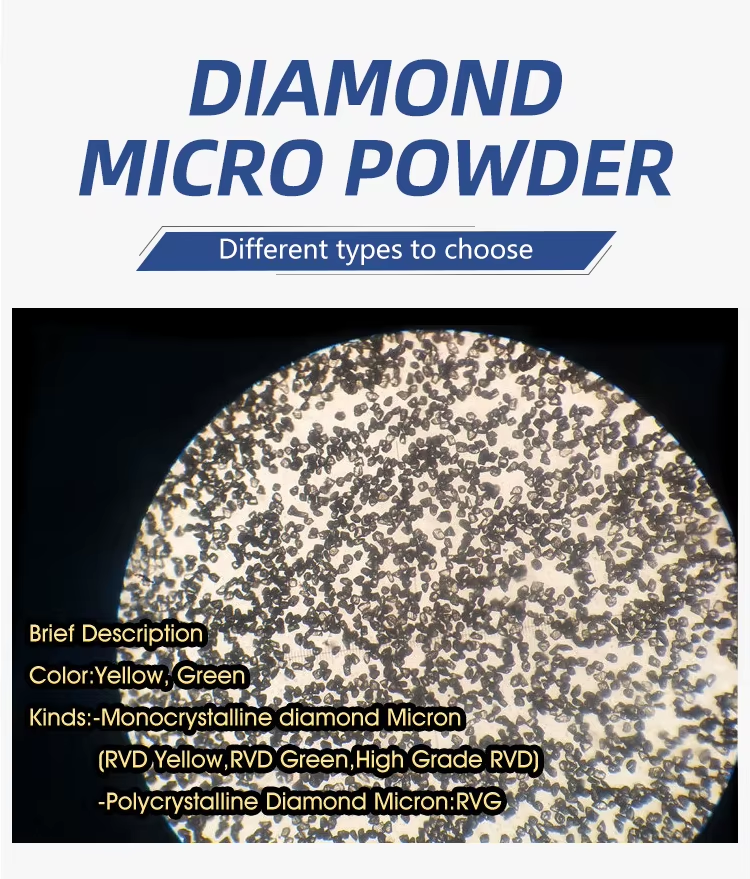

What is Micron Powder?

Where do Micron Powder Use?

- Fishing &Polishing all kinds of hard brittle materials

- Processing Ferrous Materials

- Processing Tungsten Carbide,PCD DIE,Stone Materials,Stone Materials,Ceramics,gems&Opital glass,PCD..

- Machinery,electronics,aerospace,aviation,and high-tech areas

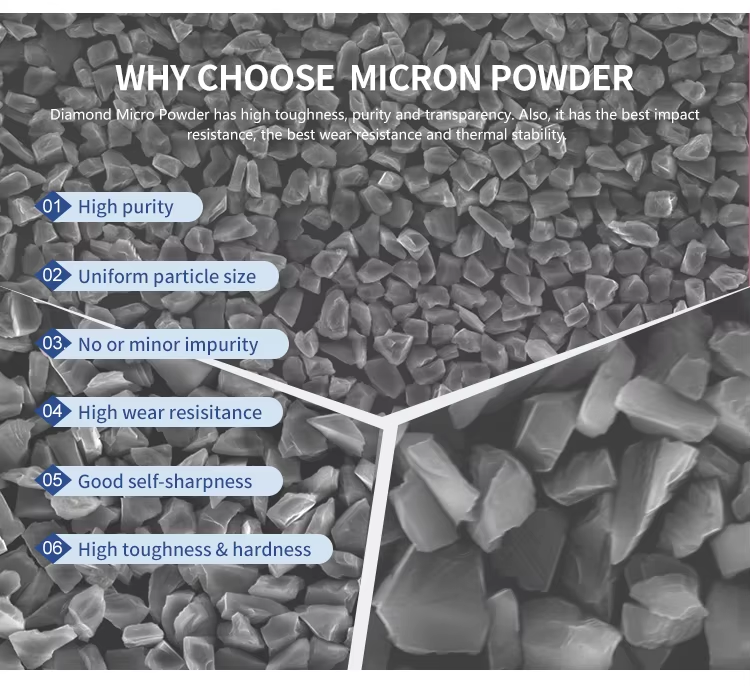

Why Choose Micron Powder?

- High strength,pure quality diamond as raw materials

- Use RVD Diamond as raw materials,good self-sharpness

- Complete specification,perfect thermal stability,epigranular

- Low content of impurities,perfect shapes and surface performance

- Powderful grinding force,high wear resisitance and good lubricity PTFE matrix

- Purity is more than 99%,which has reached the international level

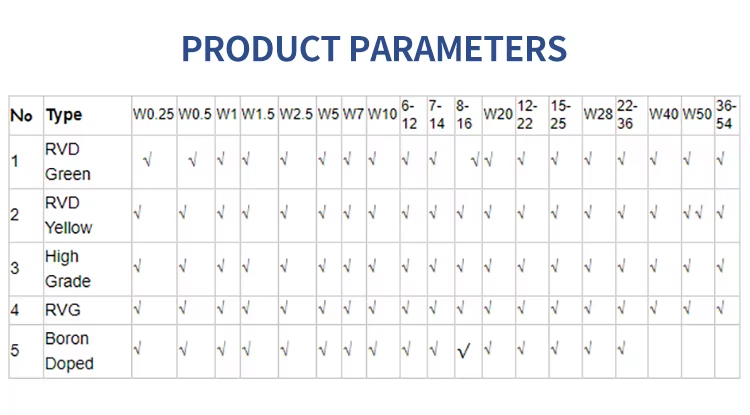

Type of Micron Powder

What is RVD Green

Micron?(For Monocrystalline diamond)

It's made from RVD green,it is lower than RVD Yellow in quality

What is RVD Yellow Micron ? (For Monocrystalline diamond)

It's made from RVD Yellow,has the very feature of perfect work efficiency

What is High Grade RVD? (For Monocrystalline diamond)

It's made from High Grade Diamond Grits,the highest Grade RVD Quality

What is RVG Diamond Micron? (For Polycrystalline diamond)

It's made from RVG Diamond Grits,it's black,low intensity ,good self-sharpness,applied to

high precessing efficiency.

What is Boron Doped Diamond Micron?(For Boron Doped diamond)

It's made from Boron Doped Diamond Grits,has the feature of regular diamond,low resistance,higher oxidating temperature,and excellent semiconductor.

For more details please contact us freely ^______^

| Name :Simon | skype: simon_xiong2 |

TEL: +86 731 84890200 | Email :enquiry(at)3betterdiamond.com |

| Whatspp/Wechat :+86-18973163713 | website: www.diawheels.com;www.pdcinsert.com |