Горячая Распродажа цифровая офсетная передачи тепла струйная печатная машина 60 см DTF принтера с печатающей головкой миксер для сухого и I3200-A1/4720 печатающая

- Категории: >>>

- Поставщик: Guangzhou,Xin,Flying,Digital,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

About shipping costs: We cooperate with dozens of shipping companies and freight forwarders. You only need to provide the delivery address, and we will provide you with the fastest and cheapest shipping method. >>>>>>>>>>>>>>>Click here for more shipping information

————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

DTF Printing is also referred to as Direct To Film Printing, and it works by printing transfers that are heat pressed to a variety of garments (and other substrates).

When you have this machine, you can…Print on any kind of fabric, no matter dark or light. There can be more varieties in your product line. Save labor costs, and one employee can operate the machine. Faster production can print 900+ sq feet in a day.

This is our new upgraded DTF model :T602+H650

Its core Components is Epson i3200-A1 heads, it is the most stable printer heads in the market for now .

It has three thousand and two hundred nozzles, very high quality with 3200DPI high density resolution.

This printer’s speed is fabulous. It can print 12 square meter per hour.

To keep the printer's stable, we match up the model with Hoson mainboard.

After testing, it can reuduce and solve 90% of printer heads burning problems, when using Hoson mainboard on the printer,

and the printing color also will be much more colorful.

We install a heating device at the back of the printer.

It can prevent the powder residues and ink flow, as pet film got damp.

The DTF printing machine is a new generation of digital revolution, pioneering and leading the new digital offset pyrography technology.

The printing machine to make up the exisiting process of the short board, just print+press, 2 steps to compelet the printing.

New heat tranfer printing materials and unique printing effect, no cutting waste, perforation breathable, colorful.

No limitation on fabric material, color, transfer effect, no fear of washing, fastness up to 4.5.

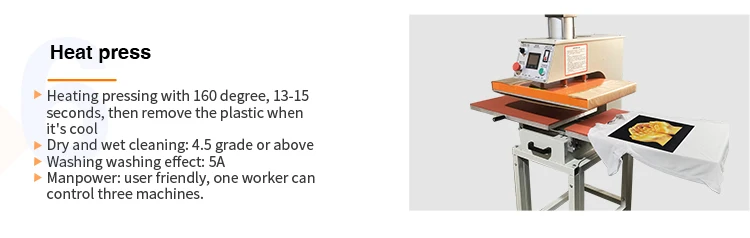

Transfer temparature 160-170 degrees, 10-15 seconds, cold tear, the specific temparature according to different fabrics.

It can replace traditional, plane hot stamping, offset hot stamping, korean hot stamping and screen printing. Printing without plate making requirements, as soon as

printing, hot stamping without bur, no exposure, soft handle, no fading, strong color fastness, strong tensile strength, no cracking, no requirements on cloth, simple

operation process.

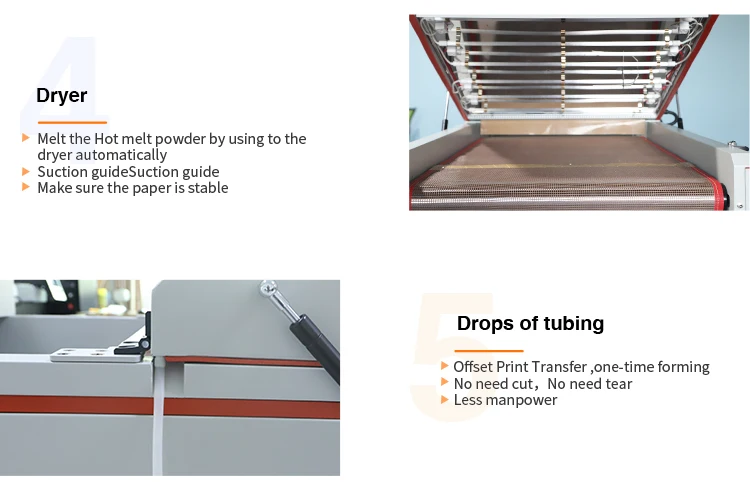

XinFlying PET film heat printing machine, whole set have two machines: one is inkjet printing machine with CMYK+W heat transfer pigment ink, one is powder shaking

machine.The first step is print CMYK+W ink to pet film. The second step is put the hot melt powder to printed film and shaking powder, dryer the film and picture.Then

the printed film be finished. After the above two step, heat transfer picture to garment, bag, leather and so on. Many fabric material suitable for this printing process.

No limited fabric of this printing, easy to operate.

Incredible Overall Value!

When you buy a DTF machine, what you will get is not only a machine.

1 Year Warranty

Within 1 year from the date of purchase, if the machine has non-man-made damage, you can enjoy free warranty service.

Rip Software

Buy a machine and you will get a $500 worth of rip software for free. SAI FLEXI, MainTop for option.

DTF Starter Kit

Starter kit pack including DTF PET Film, DTF Inks, Powder, and the user's guide.

Online Technical Support

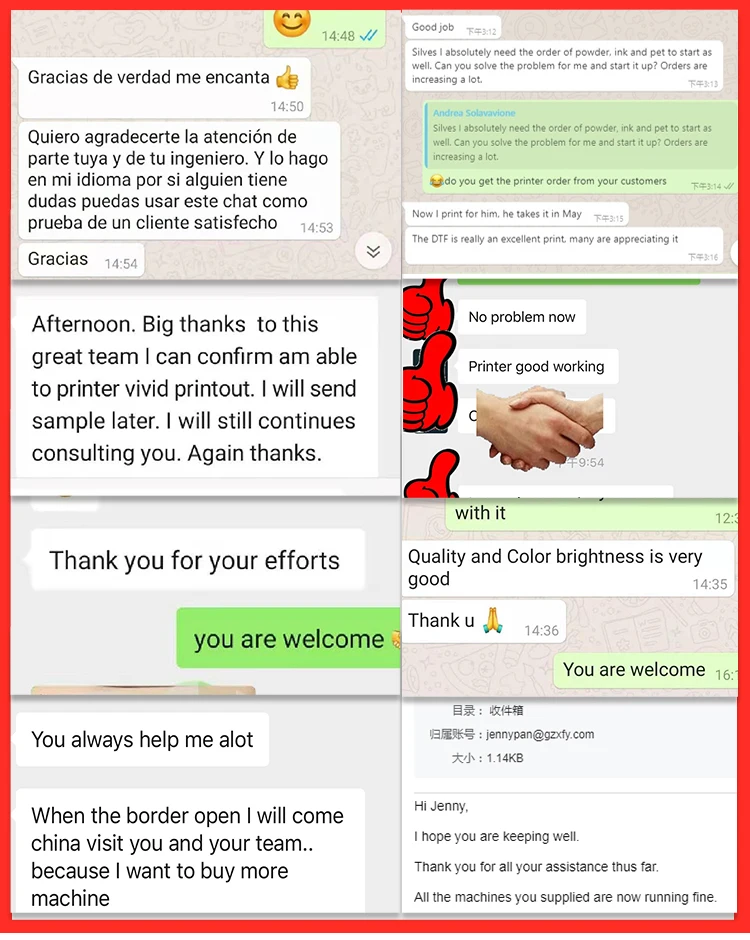

The expert team will serve you online and solve any problems you encounter for free.

| Model | XF-E602 Heat Transfer Film Printer |

| Printhead | 2*Ep I3200-A1/4720 |

| Print speed | 4 pass 12 sqm/h |

| 6 pass 10 sqm/h | |

| Print Width | 70cm |

| Ink Colors | C M Y K + W |

| Ink Type | Pigment Ink |

| Consumption | CMYK+W is 25ml/sqm |

| RIP Software | PrintFactory (PF) |

| Interface | USB2.0 USB3.0 |

| Print File Format | BMP, TIF, JPG, PDF Etc. |

| Heating System | Extra Front Heating System |

| Feeding Method | Roll to Roll, Leaf |

| Color Management | ICC Based; Density & Curves Adjustable |

| Power Supply | 50HZ/60HZ, AC 220V, 10A |

| Packing Size (L*W*H) | 2040*740*840mm |

| Machine Weight | 180KG |

| Working Environment Temperature | 20C-35℃ (68F-95F) |

| Working Environment Humidity | 35%-65%Rh |

Among the existing printing solutions, DTF(Direct to Film) Digital Transfer Technology is the best and most perfect transfer method solutions.

Automatic Powder Recycle

The new generation DTF machine configured automatic recycling powder, more cost-effective than manual recycling.

Vacuum Suction Conveyor Belt

Vacuum adsorption conveying platform, absorbing the print material to ensure that the material does not bulge or run off.

Advanced White Ink Circulation System

The white ink circulatory system prevents sediment causing the nozzle to be blocked.

Ink Low Alarm

Automatically alarm and prompt to refill the ink in time to continue printing When the ink is almost used up.

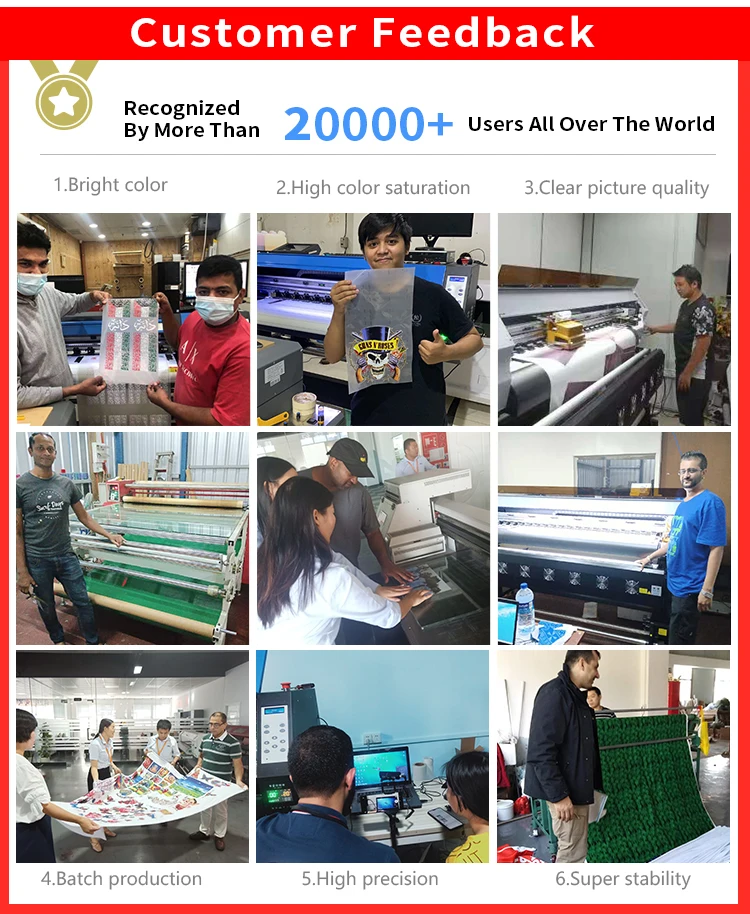

At present, XinFlying products have been sold to all over the world, including U.S.A., Canada, Germany, Poland, Brazil, Peru, Australia, Russia, Singapore, South Africa, India, Thailand, Philippines, Pakistan and other more than 30 countries. And we have cooperated with several professional company both at home and abroad for long-term, stable relations of cooperation, becoming excellent supplier of the world famous printing companies.

After-Sale Service:

1. If you use our ink, we will always provide you with free repair service

2. technologists can speak fluent english and provide instant online support service

3. free technical training will be provided in the f actory

4. we will send you spare parts and inks in lower price

5. we can issue you excludsive dealership after we confirm our cooperation and we will 100% loyal to our dealers

6. we can arrange technicians to visit you for supporting the booth and training freely if you display our machines in exhibition.

Machine Maintenance Instructions:

1. As for the ink cap, scraper and lifting plate clean, must be kept clean all the time.

2. Need to put some lubricating oil on the trolley track for every half a month or for every month .

3. Grating need be wiped with dry clean fabric for every month.

4. Need to put some water into the ink stack cap while the the machine is printing. It greatly keeps the ink cap wet to prevent agglomeration and the print head blocked.

5. It is best to turn on the machine in two or three days if you do not use the machine for long time. And print the test strip or print some tasks to prevent the print head blocked.

6. The machine need to be kept cleaned all the time . If can kept like a new machine, which will better.

FAQ

Q: What’s the machine installation?

A: We provide the machine usage & installation videos and instruction manual, afford the 24 hour online service support for oversea customers. If need, we could provide the on-site installation and training service.

Q: How about the machine’s package and transportation ?

A: Each machine before leave the factory will be protected by film, be fastened on the bottom of the wooden case with iron nails, after the machine be packed, we will choose the transportation way and export service according customer’s requirement.

Q: How about the machine’s maintenance ?

A:With warranty of whole printer ( not included the printer head) , simultaneously we will provide the lifetime warranty if use together with our ink. Also our after-sales engineers will provide 24 hour online technical consulting service.