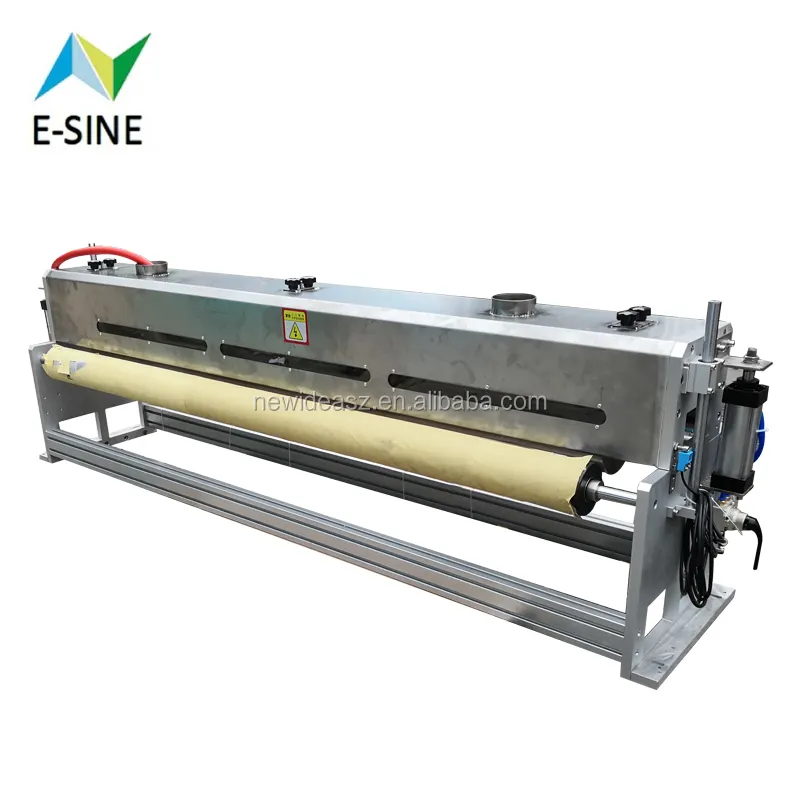

Машина для производства резиновой подошвы/машина

- Категории: Other Plastic & Rubber Machinery >>>

- Поставщик: Wenzhou,Tiangang,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

rubber shoe sole making machine/rubber sole machine/rubber machine

1. It adopts intelligent man-machine interface and PLC program control, and the calculation is accurate.

2.The machine meets the requirements of humanized design, is easy to operate, automatically opens and closes the mold, and saves labor costs.

2.The machine meets the requirements of humanized design, is easy to operate, automatically opens and closes the mold, and saves labor costs.

3.The closing and clamping mechanism adopts a unique special structure with relatively high clamping force, so that the product has no raw edge.

4.The moving an sittig mechanism of the shooting table adopts the rotation of the helical gear and the precise control of the computer of the same service mechanism,so that the moving stability is good and the positioning is more accurate.

5.Energy saving and very-low power consumption, which is about 30% less power than traditional vulcanized rubber machines.

6.High output the daily output of a single pair of molds reaches 350-450 pairs, which is more than double the output of traditional vulcanized rubber machines.

4.The moving an sittig mechanism of the shooting table adopts the rotation of the helical gear and the precise control of the computer of the same service mechanism,so that the moving stability is good and the positioning is more accurate.

5.Energy saving and very-low power consumption, which is about 30% less power than traditional vulcanized rubber machines.

6.High output the daily output of a single pair of molds reaches 350-450 pairs, which is more than double the output of traditional vulcanized rubber machines.

Production product

Injection rubber has excellent wear resistance, and is often used in ordnance, Martin boots, high-grade leather shoes, etc,

Production product

Injection rubber has excellent wear resistance, and is often used in ordnance, Martin boots, high-grade leather shoes, etc,

Single station control

Full-automatic mold opening, automatic induction, automatic injection molding, efficient, reducing labor

Control system

Adopt the button of Omron in Japan

Electric control panel

Adopt a full range of Schneider electric appliances

Solenoid valve

Solenoid valve of Taiwan technology, with long service life

Video conference

Video conference remote support

Exhibition

More than 10 domestic and foreign exhibitions every year, including Africa, Türkiye, Vietnam, India, Pakistan, Indonesia, etc. We are looking forward to visiting you

Specification

Raw Material: Rubber

Station: 6

Power: 47 kw

Weight:12000 Kg

Specification

item | value |

Raw Material | Rubber |

Station | 6 |

Power | 47kw |

Weight | 12000 |

Packing & Delivery

Iron framed. wooden box

Company Profile

Wenzhou Machinery Co., Ltd. is a design, manufacturing and marketing as one of professional shoe-making equipment manufacturers.

The main production injection foam soles injection molding machines, color, color, three-color, four-color and color mixing disc injection molding machine series, color disc injection molding machine series,

TR / TPU disc and vertical injection molding machine series, TRB monochrome, color disc injection series, servo series.

High-technology products, unique manufacturing processes, stable and reliable quality, excellent reputation in the footwear industry, many domestic shoe factories and shoe factories primary or sole supplier.

The company has a group of experienced, energetic, developed a first-class level of professional and technical team, most of the company's products patented.

Strong technical strength has been a lot of well-known foreign footwear firms.

The company also has a heartfelt solidarity, hard-working, honest and pragmatic, energetic, pioneering marketing and service teams.

Companies to import quality operation system, scientific management, trust the staff's efforts and dedication, and respect for labor rights of employees to create a good working environment and development platform for employees; metalworking, stamping and decoration complete production lines, improve the detection means, thereby ensures greater production capacity and product quality is stable and reliable, and strive to provide customers with high-quality specialized products and services, with a sincere quality win their respect and trust.

The main production injection foam soles injection molding machines, color, color, three-color, four-color and color mixing disc injection molding machine series, color disc injection molding machine series,

TR / TPU disc and vertical injection molding machine series, TRB monochrome, color disc injection series, servo series.

High-technology products, unique manufacturing processes, stable and reliable quality, excellent reputation in the footwear industry, many domestic shoe factories and shoe factories primary or sole supplier.

The company has a group of experienced, energetic, developed a first-class level of professional and technical team, most of the company's products patented.

Strong technical strength has been a lot of well-known foreign footwear firms.

The company also has a heartfelt solidarity, hard-working, honest and pragmatic, energetic, pioneering marketing and service teams.

Companies to import quality operation system, scientific management, trust the staff's efforts and dedication, and respect for labor rights of employees to create a good working environment and development platform for employees; metalworking, stamping and decoration complete production lines, improve the detection means, thereby ensures greater production capacity and product quality is stable and reliable, and strive to provide customers with high-quality specialized products and services, with a sincere quality win their respect and trust.

FAQ

1.Are your company a trading one or a factory?

Factory + trade (integration), 30 years focusing on rubber machine design and production . OEM is also acceptable for us.

2.How to choose the most suitable products?

Our professional team will give you the best suggestion as long as you tell us what kind of product you need to do and the required specification.

3.Do you accept customization service?

Yes, of course, we can not only offer standard machines, but also customized machines according to your request. Don’t hesitate to tell us your requirement, we will try our best to meet your needs.

4.How about your warranty?

Generally, our warranty is one year. Within the warranty period, we can offer technique support and part parts change,necessarily, our engineers may go to your place for better service.

Generally, our warranty is one year. Within the warranty period, we can offer technique support and part parts change,necessarily, our engineers may go to your place for better service.

5.How about the packing for machine, is it safely protected during transportation?

Our machine is packed by standard export wooden box, it won’t be damaged. We’ve delivered many testing

machines abroad by sea or by air without damage.

machines abroad by sea or by air without damage.

6.What is the order process?

Inquiry - quotation - communication - order

confirming - deposit payment - production - testing and debugging - balance payment -packing - delivery - customer receiving-after service

confirming - deposit payment - production - testing and debugging - balance payment -packing - delivery - customer receiving-after service

Похожие товары

Замена керамического электрода enercon corona

US $500.00-$7000

Машина для производства арматуры FRP с сертификатом CE/ISO

US $23800-$65800

Стандарт Ce, линия по производству капельного орошения

US $135000-$140000