Заводская цена ковка никелевый сплав Инконель 600 625 718 738 круглые стержни по

- Категории: Nickel >>>

- Поставщик: Jiangsu,Dzx,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

Inconel 601 is a high-temperature, corrosion-resistant nickel-chromium alloy typically containing 61% nickel and 23% chromium. It can be manufactured through hot and cold working processes, typically using hot rolling, cold rolling, and heat treatment processes.

Factory Price Forging Nickel Alloy Inconel 600 625 718 738 Round Bar Rods with Good Price

Treatment process

Plate, belt, pipes supply state of 15 ℃ to 980 ℃ + solution heat treatment system, air cooling.The intermediate heat treatment system of materials and parts can be respectively adopted in the following processes.

Annealing: 955 ~ 1010 ℃, water cooling.

Weldments annealing before welding: 980 ℃, 1 h.

Weldments eliminating stress annealing: 900 ℃, moisturizing 2 h.

Eliminating stress annealing: 15 ℃ 885 ℃ +, 24 h, air cooling.

Specifications

• We can supply all kinds of bar, forging, ring, hot rolled plate, cold rolled plate, strip, pipe and wire.

Plate and strip are generally supplied after hot or cold rolling, annealing or solid solution, pickling

and polishing.

• Rods, forgings and rings may be supplied in the form of forging or hot rolling;It can also be

supplied with solid solution after forging.The bar can be polished or polished after solid solution.

When the order is required, it can be placed in the cold drawing state.

• Silk can be supplied in solid solution state.For silk materials with nominal diameter or thickness

less than 6.35mm, it can be provided with 50% ~ 65% cold drawing deformation after solid

dissolution.Silk material with nominal diameter or side length greater than 6.35mm shall be

supplied with no less than 30% cold drawing deformation after solid solution treatment.For silk

materials with nominal diameter or side length not exceeding 0.65mm, according to the

requirements of solid solution treatment, no less than 15% cold drawing deformation is provided.

Specification

Company Profile

Application

Certificate

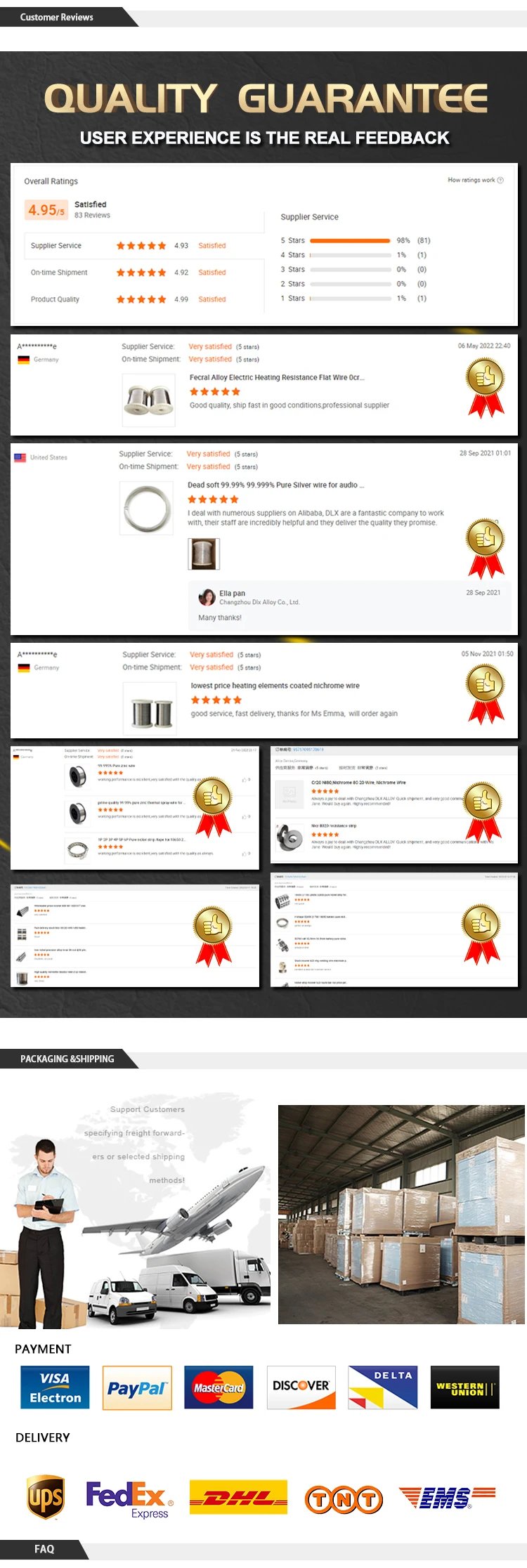

Packing & Delivery

FAQ

Q:How can I contact your company?

A:We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile

Mb./Wechat/Whatspp/ Skype: +86-13218687867 Contact: Chloe Wang

Q:What is your working time?

A:Monday-Saturday : 7:30AM-22:00PM (Beijing time, GMT+08.00)

Q:Do you provide free samples?

A:Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

Q:What is your payment terms?

A:T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

Q:What is the lead time?

A:Usually sample lead time is 7 days after payment has been confirmed.

A:We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile

Mb./Wechat/Whatspp/ Skype: +86-13218687867 Contact: Chloe Wang

Q:What is your working time?

A:Monday-Saturday : 7:30AM-22:00PM (Beijing time, GMT+08.00)

Q:Do you provide free samples?

A:Yes, we can provide a free sample for testing,buyer should bear all the shipping costs.

Q:What is your payment terms?

A:T/T, L/C, D/A, D/P, Western Union, MoneyGram, Paypal

Q:What is the lead time?

A:Usually sample lead time is 7 days after payment has been confirmed.

Recommend Products

Похожие товары

Высокое качество монель 400 лист на основе никеля сплав пластины

US $22.00-$26.00

Никелевый тигель Ni purity 99.7% 30 мл/50 мл/100 мл с крышкой

US $4.50-$18.00