Машина для прокатки листового металла

US $10000

Поделиться:

1 | Suitable to process | Color steel plate, |

2 | Width of the feeding material | 914-1250mm |

3 | Roller station | 11-18 rows or custom as customer's requirements |

4 | Thickness of feeding material | 0.3-0.8mm |

5 | 20Productivity | 20 m/min |

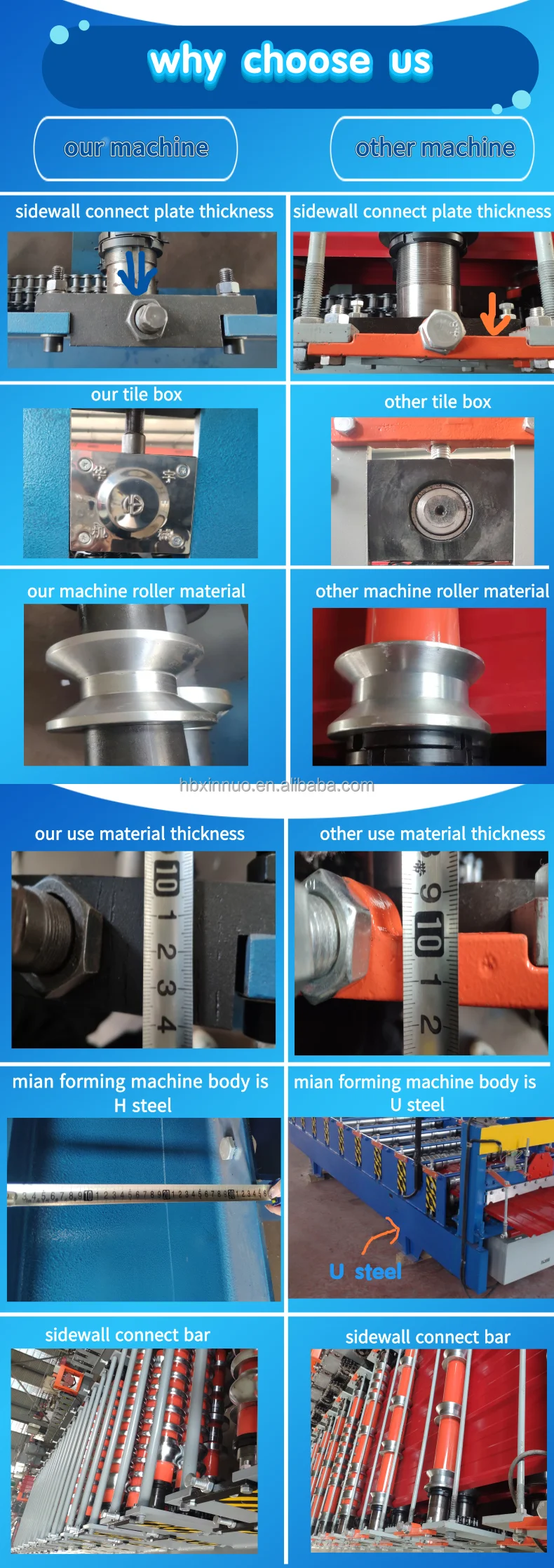

6 | Rollers' material | 45# steel |

7 | Diameter of shaft | 70-80mm |

8 | Voltage | 380V 50Hz 3phases |

9 | Wall thickness of main forming machine | 12-18mm steel plate |

10 | Main forming machine body | 300-400 mm H steel |

11 | Motor power | 3 kw |

13 | Weight | About 1.2 T |

14 | Custom | According to customer's requirements |

Packaging Details: | Main machine is nude, the computer control box is packed with wooden frame. |

Main machine is nude in the container, the computer control box is packed with wooden packaging. | |

Delivery Detail: | 20 days |