Китайская Экологически чистая сельскохозяйственная техника оборудование для обезвоживания

- Категории: Other Farm Machines >>>

- Поставщик: Zhengzhou,Fusion,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

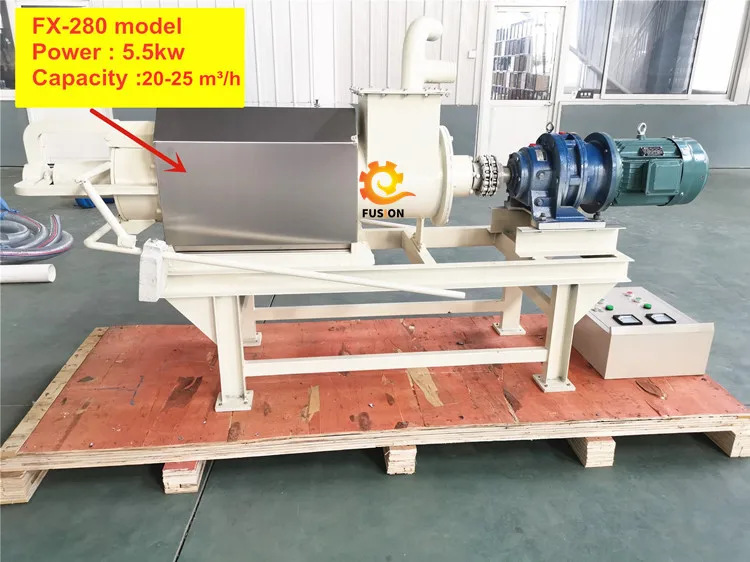

Factory supply Cow Dung Dewatering Machine/Manure Dewatering Machine/ Dewatering Screw Press Machine Solid Liquid Separator

1. Breif introduction of the Manure dewatering machine :

Screw dewatering for animal manure is mainly composed of control cabinet, pipeline, pumps,body, mesh screen, main motor , reducer, Feed inlet, water outlet , dry material outlet and other parts. This equipment is widely used and has been widely used and ecognited in the market.

2.Technical parameters:

Model | FX-180 | FX-200 | FX-280 |

Voltage | 380V | 380V | 380V |

Main Power | 4kw | 4kw | 5.5kw |

Pump power | 3kw | 3kw | 3kw |

Machine Size | 2000*600*1300mm | 2200*610*1350mm | 2400*800*1300mm |

Weight | 340kg | 510kg | 680kg |

Capacity | 10-15 M³/H | 15-20 M³/H | 20-25 M³/H |

Screen inner diameter | 180mm | 200mm | 280mm |

Feed inlet diameter | 76mm | 76mm | 76mm |

Water outlet diameter | 110mm | 110mm | 110mm |

| Body Material | Carbon steel & 304 stainless steel | Nodular cast iron& 304 stainless steel | Nodular cast iron& 304 stainless steel |

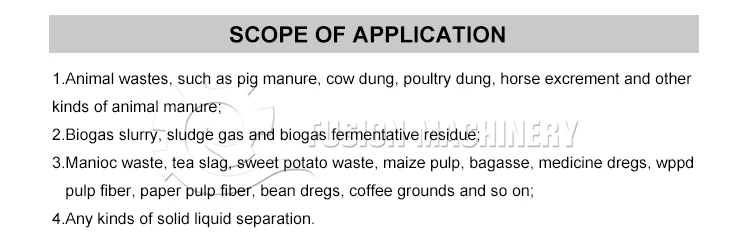

3. Scope of application:

It maily dewatering animal manure (such as pig manure,Cow dung, ).Dung dewater can separate the animal dung into liquid organic fertilizer and solid organic fertilizer.

Usually, manure after dewatered is like sand. It is scattered when you grab it with your hand.

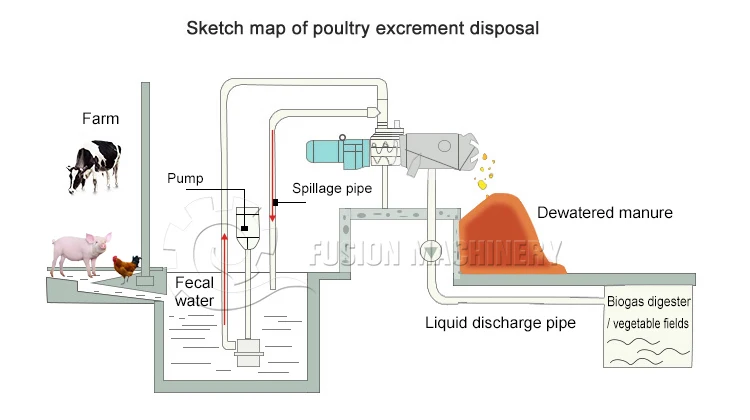

4. working principle:

It separates the moisture and the animal manure by screw extruding extrusion technology.

First, When the cutting feed pump pushs the animal manure to the screw dewatering machine through the pipeline, the dewatering machine start to work.

The screw gradually pushes the animal manure to the front of the body. And at the same time, increases the pressure, forcing the moisture in the raw material to squeeze out from Mesh screen, flowing out of the drain pipe.

In order to grasp the discharging speed and moisture , the adjusting device in front of the main machine can be adjusted to achieve your requiremnet.

5. Features and advantages :

(1) Save space , Low speed, operate easily , low cost,fast investment recovery, environmental protection, low power consumption, suitable for continuous operation.

(2) The material of important parts are304 stainless steel, such as screw, screen, etc.

Screw : Fully welded,304 stainless steel, 8mm thickness blade, corrosion protection, wear resistant .

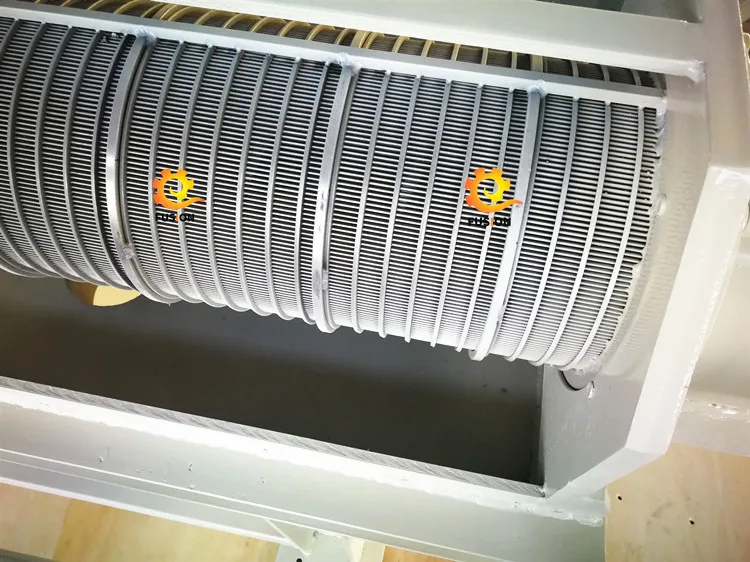

Screen mesh : 304 stainless steel, 0.3-2mm models for your choice .

Machine outside body material : using Nodular Cast Iron technology, thickness up to 18mm. So durable.

Screen mesh picture dispaly:

Screw picture display:

Screw pupm:

Delivery picture display : (Main machine + electric control box+ 10m pipe+ pump+ 2 m pvc pipe)

36 sets FX-280 model delivery picture display :

Are you confused about the following questions?

1.When will you ship the machine?

Normally 10-15 working days after deposit payment.

2. What is the payment terms ?

Pay 30% as deposit , pay last 70% before shipping by TT or Alibaba .