90 градусов Двусторонняя Угловая головка ER32 прямоугольная с ЧПУ обрабатывающий центр аксессуары для

- Категории: >>>

- Поставщик: Suzhou,Baoshang,Import,&,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

1. We are the source manufacturer and support non-standard customization.

2. We can provide complete specifications of right Angle head, universal Angle head, extension Angle, etc. We can also customize processing according to your needs and requirements, and carry out comprehensive debugging and testing before delivery

3 We are engaged in Angle head and machine parts for more than 10 years, with rich experience to provide you with comprehensive technical support and perfect after-sales service, we sell Angle head original imported products, each product has its own positioning.

Technical specification

Product name | BT40-GXER32x2-175 |

Rotate speed | Up to 4000RPM |

Torsion | 60N.m |

Clamping range | 1---20mm |

Gear ratio | 1:1 |

Tapping | Max M16(S45C) |

Spindle rotation | CW--CW--CCW |

Weight | 10kg |

Our advantages

--------- We are very familiar with the products we sell, tell us your processing requirements, we will recommend suitable products for you, with high efficiency, high precision requirements to reduce the secondary clamping, improve production efficiency, for you to save costs and improve efficiency.

Precautions for installing Angle head

1. Before installing the 90 degree Angle head, it is necessary to confirm that the bracket is fixed, the screw fixing ring is

tightened, the screw is locked, and the quick screw is not loose.

2. Check whether the fixed block matches the mounting hole on the spindle end face of the machine tool. If not, it is recommended that the support adopt a quick positioning system.

3. The reference position must be corrected before machining, and the screws must be locked after correction.

4. When the Angle head is not in use, do a good job of preservation and rust prevention

5. After the installation of Angle head and side milling head, check whether the lever is detached from the fixed groove of the fixed ring. If not, please do not start machining.

6. Do not hit the Angle head housing with gravity, otherwise it may cause damage to the Angle head

7. When the Angle head is working, the speed should be within the allowable range of the Angle head

Angle Head Application

Company Profile

WE FOCUS ON THE PRODUCTION AND SALE OF CHECKING FIXTURES COMPONENTS FOR 10 YEARS, SUCH AS UNIVERSAL ANGLE HEAD, RIGHT ANGLE HEAD, CUSTOM COLLECT, ENDMILLINGS, TOOLING BALLS, TOOLING BALL ASSEMBLY, CHECKING PINS&BUSHINGS, GO NO GO GUAGE, PLUG GAGE, MECHANISM, SLIDERS, CLAMPS, SUPPORTS, RECOIL HOSE, BALL FILLERS, etc.PARTIAL

MACHINES SHOWN

MACHINES SHOWN

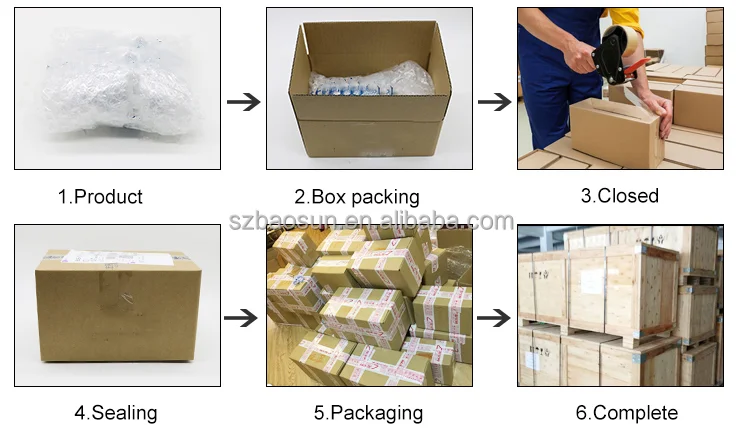

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging serviceswill be provided. As shown.

In order to better satisfy customers' request for time, we support 3 kinds of different speed transportation, Sea, Air, Express are available.