Ленточные шлифовальные станки с ЧПУ контроллер барабанный шлифовальный станок деревообрабатывающий

- Категории: Other Woodworking Machinery >>>

- Поставщик: China(Shandong),Samet,Intelligent,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

1. The use of air bag sanding pad has high sanding accuracy and good effect. The front microcomputer control panel is easy to operate, Flexible and fast。

2. In case of failure, equipment power failure, braking, and conveyor bed production protection drops may protect drops Workpicefrombeingdestroyed。3. Advanced dynamic balance detection fixed thickness roll, steel roll, pulley, because the machine Runmoresmoothly。

4. The sand frame adopts steel structure body structure, with small deformation and good shock absorption effect.

5. High power transmission speed control, strong transmission capacity and high production efficiency.

6. Insufficient air pressure or sand belt fracturing, from dynamic shutdown to ensuring safety.

Machine Parameters

Processing sheet width | 1300mm |

Processing sheet thickness | 2-150mm |

Processing plate length | ≥550mm |

A sand frame motor power | 30KW |

Two sand frame motor power | 22kw |

A sand frame abrasive belt line speed | 19m/s |

Second sand frame abrasive belt line speed | 18m/s |

Conveyor belt motor power | 3kw |

Feeding speed | 0-22m/min |

Working table lifting motor power | 0.37kw |

Brush motor power | 0.37kw |

working pressure | 0.55Mpa |

Compressed air consumption | 1.56 cubic meters per minute |

where the control circuit | 0.9 cubic meters |

weight | 3400kg |

Details Images

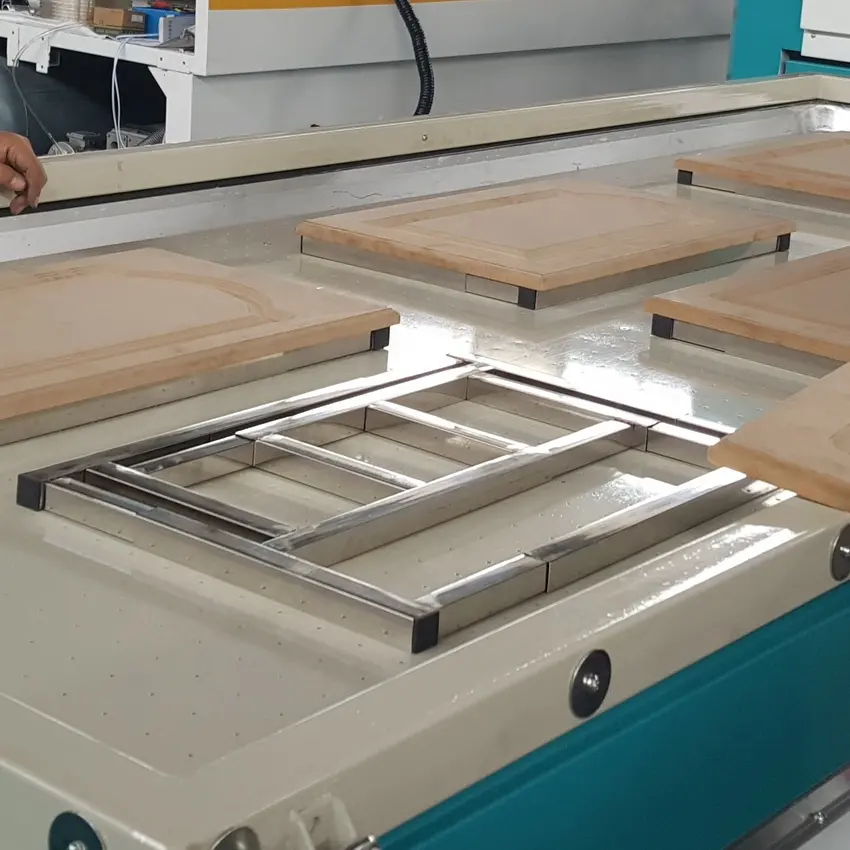

Two rollers one pad structure

The front sand frame is an adjustable steel roller, and the rear sand frame is a combined structure

roller polishing pad, which is suitable for constant thickness sanding and fine polishing of various plates.

roller polishing pad, which is suitable for constant thickness sanding and fine polishing of various plates.

Double sand frame roller for fine grinding of the plate

The sanding component is divided into front and rear two. The front sand frame is an adjustable steel plate, and the rear sand frame is a combined structure rubber roller, which is suitable for the fixed

sanding and fine polishing of various plates.

sanding and fine polishing of various plates.

Control Panel

Simple and clear self-resetting control button, intelligent temperature controller with high temperature, smooth and easy to operate.

Electric components

Clearly wires and high quality electrical components equipped with.Then ensure the belt sanding machine with high precision and fast speed.

Application

Certifications

Product packaging

Company Profile

Jinan Junteng CNC Equipment Co., Ltd. is a scientific and technological enterprise specialized in the research, development and manufacture of automatic woodworking equipment and laser CNC equipment. After nearly 10 years of development experience, the company has a 36000 square modern chemical plant in the beautiful spring city of Jinan, and has become a reliable and reliable CNC machine manufacturer at home and abroad.

Our main products include ATC CNC machining center, 4-axis CNC machining center, high-end customized furniture production line, CNC six-sided drill, CNC machining center, CNC side hole machine, edge banding machine, sliding table saw, film coating machine, polishing machine, optical fiber cutting machine, laser engraving machine, stone CNC machining center, vibrating knife cutting machine, plasma cutting machine, 3D scanner and other woodworking machines.

FAQ

1. This is the first time I buy the machine, is it easy to operate? A: We can provide the operation manual or video for guiding.

If it is hard for you learning, we can also help you by "Team viewer" online, with telephone or Skype explain. 2. ARE YOU TRADING

COMPANY OR MANUFACTURER ? A: We are factory. 3. Can I visit your factory? A: Yes! We greatly welcome customers to visit our

factory! 4. What is your MOQ? A: Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us

your port name. There will be best shipping freight and machine price send to you.

If it is hard for you learning, we can also help you by "Team viewer" online, with telephone or Skype explain. 2. ARE YOU TRADING

COMPANY OR MANUFACTURER ? A: We are factory. 3. Can I visit your factory? A: Yes! We greatly welcome customers to visit our

factory! 4. What is your MOQ? A: Our MOQ is 1 set machine. We could send machine to your country port directly, please tell us

your port name. There will be best shipping freight and machine price send to you.