Хонинговальный инструмент для глубоких цилиндров серии JC-TGA Комбинированные Инструменты

- Категории: >>>

- Поставщик: Taizhou,Ke,Chi,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

JC-TGA series deep hole surface finish skiving and roller burnishing tool developed system

JC-TGA Skive burnishing tool

To improve fatigue strength and surface roughness,it is applied to the cutting and burnishing of inner hole contour surface.It can save a lot cost for customers.

Processing advantage

This tool is a professional tool for machining cylinder bore, especially for finishing of Cold-drawn Tube bore. It has fast efficiency and high precision. It is more than 10 times that of ordinary honing. It can process one meter in 1-3 minutes. The tool adopts reciprocating processing technology. It cuts the hole allowance when feeding forward, burnish back, and the surface roughness can reach Ra0.05-0. 2. Surface hardness can be doubled to increase the service life of cylinder.

Skills

Skiving and burnishing processes are carried out separately to help maintain low power requirements and feed force.

Feed and speed can be optimized for skiving and burnishing processes respectively.

It is the best scheme to improve tool life and machining safety.

Procssig method

Single rotary processing mode: Workpiece fixed, tool rotary feed processing

Processing method: Cutter feed into the inner hole first to finish boring and cutting the cylinder bore, to the end and return to the inner hole for burnishing processing.

Product data

Skive-burnishing tool | Cutter | ΦD/ΦG | 38-56 | 57-67 | 68-90 | 91-149 | 150-200 |

Blade | R420.37-06 | R420.37-07 | R420.37-11 | ||||

Copper guide | 300TDX | 400TDX | 500TDX | ||||

Rubber strip | 300DXT | 400XDXT | 400DXT | 500XDXT | 500DXT | ||

Tool body | TGA-xxxDT | ||||||

Roller | Conical sleeve | TGA-xxxZT | |||||

Tool support | TGA-xxxZJ | ||||||

Connection sleeve | TGA-xxxLJT | ||||||

Roller | 0625/0725GZ | 0830GZ | 1030GZ | 1435GZ | |||

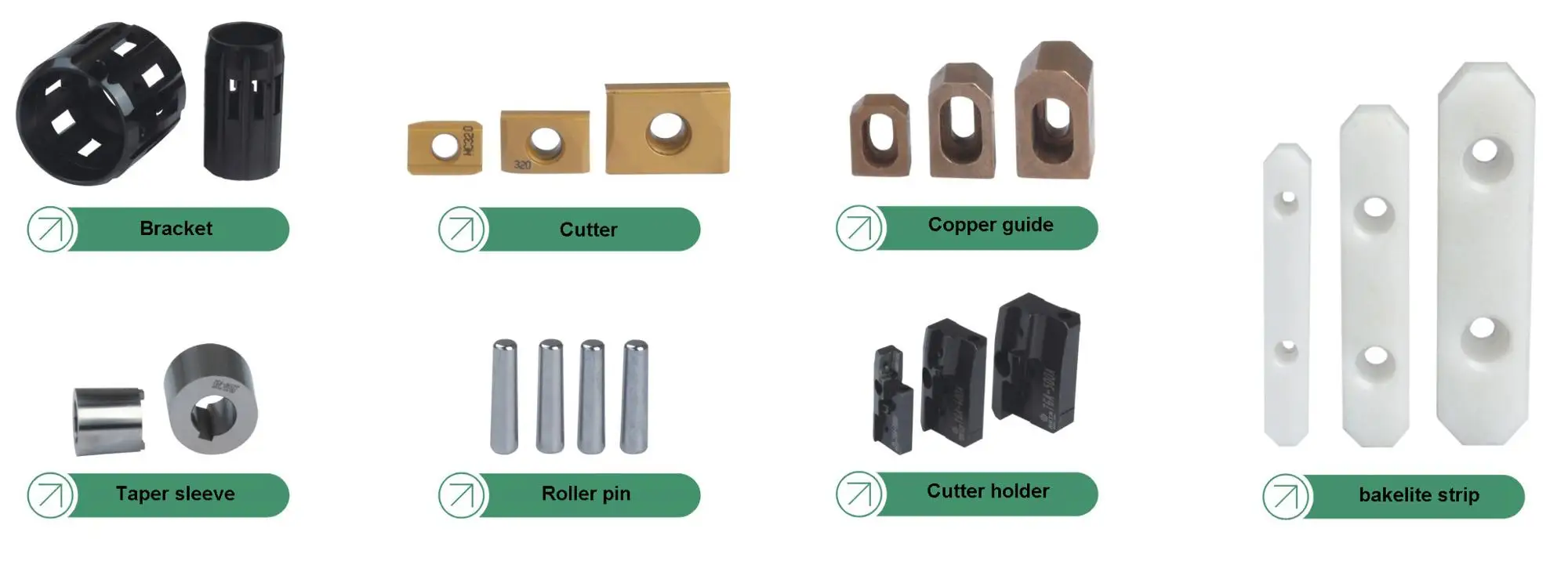

Spare parts

Application:

1.Extrusion of pipes, such as seamless steel pipes or cold-drawn pipes;

2.Diameter range: 38-300 mm

3.Typical parts: hydraulic cylinder and cylinder;

4.Machine tools with forward and backward feeding functions can provide optimum performance and maximum machine tool utilization.

Main features

1. Increasing the surface roughness, the roughness can basically reach Ra < 0.08um.

2. Amend roundness, ellipticity can be less than 0.01mm.

3. Increasing the surface hardness, eliminating the stress and deformation, and increasing the hardness by HV > 4

4. Because the surface residual compressive stress is retained on the surface, it helps to seal the surface micro-cracks and hinders the expansion of erosion, thus improving the surface corrosion resistance and delaying the generation and expansion of fatigue cracks, thereby improving the fatigue strength of cylinder barrel.

5. The rolling surface can form a cold working hardening layer, which improves the wear resistance of cylinder inner wall. Improve the quality of matching, reduce wear and tear, prolong the service life of parts, but reduce the processing cost of parts.

6. Improving processing efficiency: the processing speed is nearly ten times that of honing.

7.Optimizing working environment: low noise, no pollution, saving labor costs

8.Optimizing processing procedures: Scraping and rolling can be used as the last process to arrange processing after other processes (such as drilling oil hole, welding, turning thread, etc.) have been completed. The burns caused by traditional grinding process are effectively avoided.

Working parameter

Skiving | Tool diameter (mm) | Burnishing | |||

Speed(v) m/min | Feed(s) mm/rev | Allowance (mm) | Speed(v) r/min | Feed(s) mm/rev | |

80-300

| 1-4 | 0.6 | 38-56.9 | 500-1200 | 1-2 |

1 | 57-90.9 | 300-1000 | 1.3-2.1 | ||

1-5 | 1.6 | 91-148.9 | 100-800 | 2.2-3.0 | |

1.6 | 149-305.9 | 100-800 | 3.7-7.0 | ||

TaiZhou KeChi machinery Co.,Ltd is a company specialising in the production of mirror roller burnishing tools, rotary broach tools, knurling tools, combined skive-burnishing tool, diamond burnishing tool.And setting research and development production,sales in one integrated manufacturers.The company has its own R & D team and after-sales service team,.It focus on the mirror roller burnishing, rotary broach, knurling and other technical areas. During the past ten years, it has provided perfect solutions for thousands of customers in auto parts, aerospace, hydraulic, military, cylinder, ship, construction machinery, medical, agricultural machinery, air conditioning,motor and so on.

1. Feedback within 24 hours

2. Good english communication;

3. Professional suggestion on product;

4. Good training export sales person;

5. Could issue the C/O(certificate of origin)to customer to reduce the tax;

6. Could accept payment terms of T/T, L/C, western union, paypal and etc.

1.You are traders or manufacturers?

A: We are a factory. you are most welcomed to visit us

2.Q:What is the material of your products?

A: The material is mainly steel,Cast iron(Ductile cast iron) We can also choose material as customer requirements.

3.What is the artwork of your products,can print our logo?

A: Yes,we can provide your logo.

4.Q: What is your MOQ ?

A: 1 set per style

5.Q: What is the lead time?

A: It depends on your order quantity.

6.Q: Is it all right to make customer's own brand name?

A: That’s all right to make your own brand name.

7.Q: Where is your Loading Port

A: Shanghai or Ningbo port,China.

8.Q: What are your payment terms?

A: 30% deposit and balance T/T before shippment or L/C at sight.

9.Q: What is your company's available production capacity?

A: Usually 500 sets monthly.