Серия YGM/4R шлифовальная мельница Raymond высокого давления для продажи

13 600,00-13 900,00 $

Поделиться:

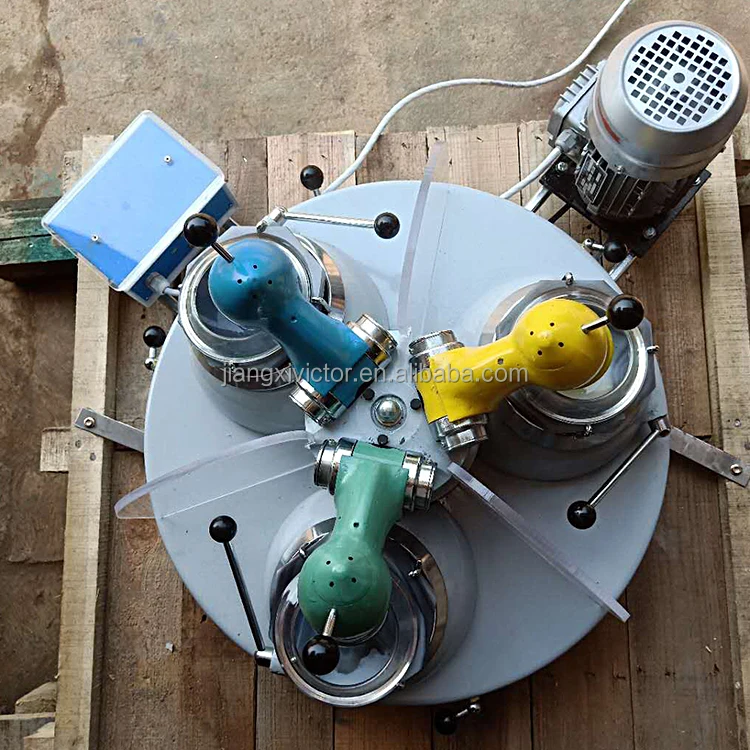

Technical Features | ||

Drive Mode | Gear Drive & Belt Drive | |

Operation Model | Two or four mill jars can be used in each grinding | |

Max Capacity | Less than 1/3 volume of each mill jar | |

Feed Size of Grinding Materials | Soft & crispy material ≤ 100mm Hard materials ≤ 3mm | |

Output Final Particle Size | The smallest particle size can reach to 0.1μm | |

The smallest particle size can reach to 0.1μm | 1/2 | |

Rotational Speed Ratio | 72 Hours | |

Mode of Speed Control | Frequency Inverter | |

Available Materials of Mill Jars | Tungsten carbide, Agate, 304 Stainless steel, 316L Stainless steel, Corundum, Zirconia, Nylon, PU,Alumina ceramic, PTFE, and etc. | |

Parameter Table (I) of Laboratory Full-directional Planetary Ball Mill | ||||||||

Model No. | Specifications | Matchable Sizes | Working Positions | Matchable Sizes | ||||

of Mill Jars | of Vacuum Mill Jars | |||||||

QXQM-0.4 | 0.4L | 50ml, 100ml | 4 | 50ml | ||||

QXQM-1 | 1L | 50ml-250ml | 4 | 50ml. 100ml | ||||

QXQM-2 | 2L | 50ml-500ml | 4 | 50ml, 100ml, 250ml | ||||

QXQM-4 | 4L | 250ml-1000ml | 4 | 50ml-500ml | ||||

QXQM-6 | 6L | 500ml-1500ml | 4 | 50ml-1000ml | ||||

QXQM-8 | 8L | 1L-2L | 4 | 500ml-1500ml | ||||

QXQM-10 | 10L | 1L-2.5L | 4 | 1L-2L | ||||

QXQM-12 | 12L | 1L-3L | 4 | 1L-2L | ||||

QXQM-16 | 16L | 2L-4L | 4 | 1L-2L | ||||

Technical Parameter Table (II) of Laboratory Full-directional Planetary Ball Mill | ||||||||||||||

Model No. | Power (KW) | Voltage | Revolution Speed (rpm) | Rotation Speed (rpm) | Total Timing (min) | Alternating Run Time of Forward & Reversal Rotation (min) | Noise≤db | |||||||

QXQM-0.4 | 0.75 | 220V-50Hz | 35-335 | 90-870 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-1 | 0.75 | 220V-50Hz | 35-335 | 70-670 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-2 | 0.75 | 220V-50Hz | 35-335 | 70-670 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-4 | 0.75 | 220V-50Hz | 35-335 | 70-670 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-6 | 0.75 | 220V-50Hz | 35-335 | 70-670 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-8 | 1.5 | 220V-50Hz | 35-290 | 70-580 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-10 | 1.5 | 220V-50Hz | 35-290 | 70-580 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-12 | 1.5 | 220V-50Hz | 35-290 | 70-580 | 1-9999 | 1-999 | 60±5 | |||||||

QXQM-16 | 3 | 380V-50Hz | 30-255 | 60-510 | 1-9999 | 1-999 | 60±5 | |||||||

Technical Parameter Table (III) of Laboratory Full-directional Planetary Ball Mill | ||||||||

Model No. | Power | Speed Control Mode | Net Weight | Dimensions | ||||

(KW) | (kg3) | (mm) | ||||||

QXQM-0.4 | 0,75 | Frequency Control | 136 | 900*570*670 | ||||

QXQM-1 | 0.75 | Frequency Control | 317 | 1330*770*850 | ||||

QXQM-2 | 0.75 | Frequency Control | 317 | 1330*770*850 | ||||

QXQM-4 | 0.75 | Frequency Control | 317 | 1330*770*850 | ||||

QXQM-6 | 0.75 | Frequency Control | 317 | 1330*770*850 | ||||

QXQM-8 | 1.5 | Frequency Control | 420 | 1360*850*950 | ||||

QXQM-10 | 1.5 | Frequency Control | 420 | 1360*850*950 | ||||

QXQM-12 | 1.5 | Frequency Control | 420 | 1360*850*950 | ||||

QXQM-16 | 3 | Frequency Control | 550 | 1530*940*1100 | ||||