Хорошее качество ультразвуковой преобразователь подводный

- Категории: Cleaning Equipment Parts >>>

- Поставщик: Shenzhen,Jiayuanda,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Good quality ultrasonic transducer underwater adjustable frequency ultrasonic transducer

Ultrasonic transducer is a component that utilize the piezoelectricity for actualize electroacoustic conversion.jydsonic ultrasonic cleaning transducer are used where powerful ultrasonic wave must be generated, such as in cleaning equipment and easy to instal. These transducers are mounted into a structure that can be bolted almost anywhere.The function of the ultrasonic transducer is to convert the input electrical power into mechanical power (ie, ultrasonic waves) and then pass it out, while consuming a small portion of the power itself.The components of the ultrasonic transducer include an outer casing, a matching layer, that is, an acoustic window, a piezoelectric ceramic disk transducer, a backing, and an extraction cable. It also includes an array receiver consisting of an extraction cable, a transducer, a metal ring, and a rubber gasket.Ultrasonic transducers can be divided into piezoelectric transducers, sandwich transducers, cylindrical transducers, inverted horn transducers, and the like.We use high-quality piezoelectric ceramics and imported metal materials, adopt advanced and reasonable production technology and strict process control to ensure the performance, stability and reliability of ultrasonic transducer products.

Main Features:

1. High mechanical quality and excellent electro-acoustic conversion efficiency, providing a high output amplitude.

2. Piezoelectric element offer a high speed of vibration. Through bolt-on mounting, mechanical intensity and amplitude have been improved.

3. Having steady output amplitude even the load markedly changed.

4. Extended using temperature, ensuring good amplitude linearity. Lower resonant impedance , ensuring high conversion efficiency.

5. Bolt-on mounting gives the fast, easy installation and high reliability.

Application:

•Strong cavitations,powerful and effective, quick detergence.

•Automotive and aerospace industry,mechanical industry,plating industry etc.

Packaging & Delivery:

packaging detail:export carton

delivery detail:within 5-15 days

Quality & Inspection:

•Cooperated with good reputation suppliers.

•100% check spare parts quality which produced from matching suppliers.

•QC checking each step from spare parts to production on the full of line.

1. who are we?

We are based in Guangdong, China, start from 2008,sell to Southeast Asia(30.00%),Mid East(30.00%),North America(20.00%),Western Europe(5.00%),Southern Europe(3.00%),South America(2.00%),Eastern Europe(2.00%),Oceania(2.00%),Eastern Asia(2.00%),Central America(2.00%),Northern Europe(2.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Ultrasonic Cleaning Equipments,Ultrasonic Welding Equipments

4. why should you buy from us not from other suppliers?

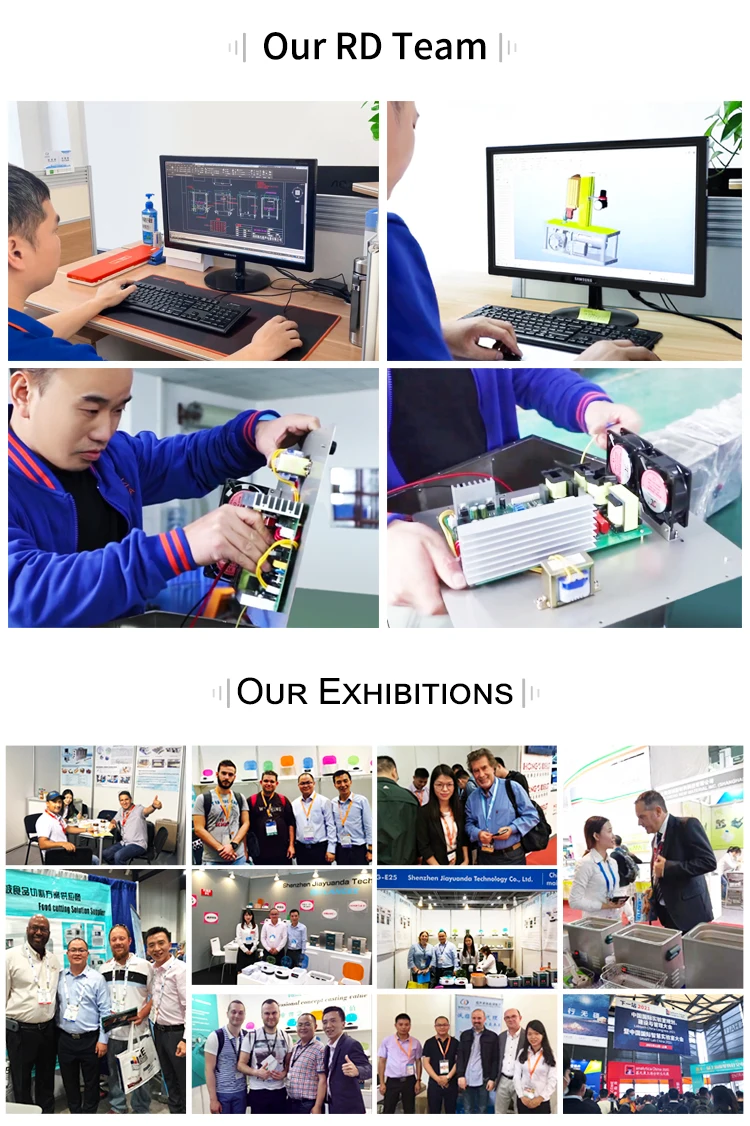

Shenzhen Jiayuanda Technology Co., Ltd. is a manufacturer which dedicated to the ultrasonic products research and development, production, services and sales. We also have a professional R&D team,so stable and good quality is undoubted.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,DDP,Express Delivery;

Accepted Payment Currency:USD,EUR,HKD,CNY;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Cash;

Language Spoken:English,Chinese