Производитель деталей для литья под давлением строгий допуск точность алюминиевые детали услуги по изготовлению

- Категории: >>>

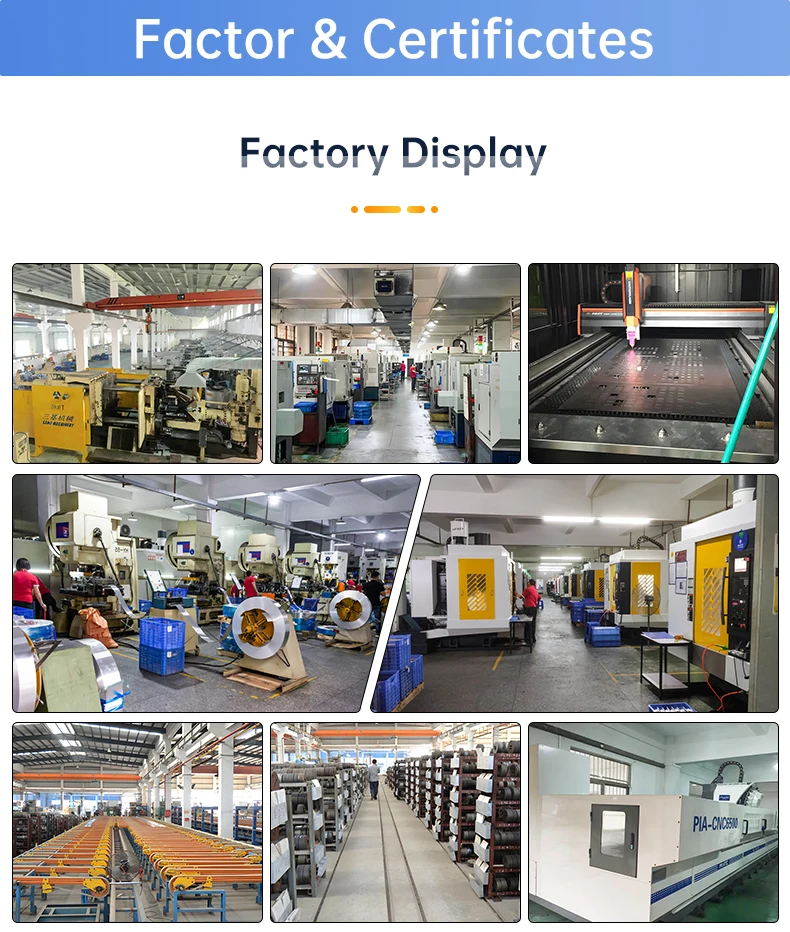

- Поставщик: Dongguan,Formal,Precision,Metal,Parts,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Die Casting Parts Manufacturer Strict Tolerance Precision Die Casting Aluminum Parts Fabrication Services Machining

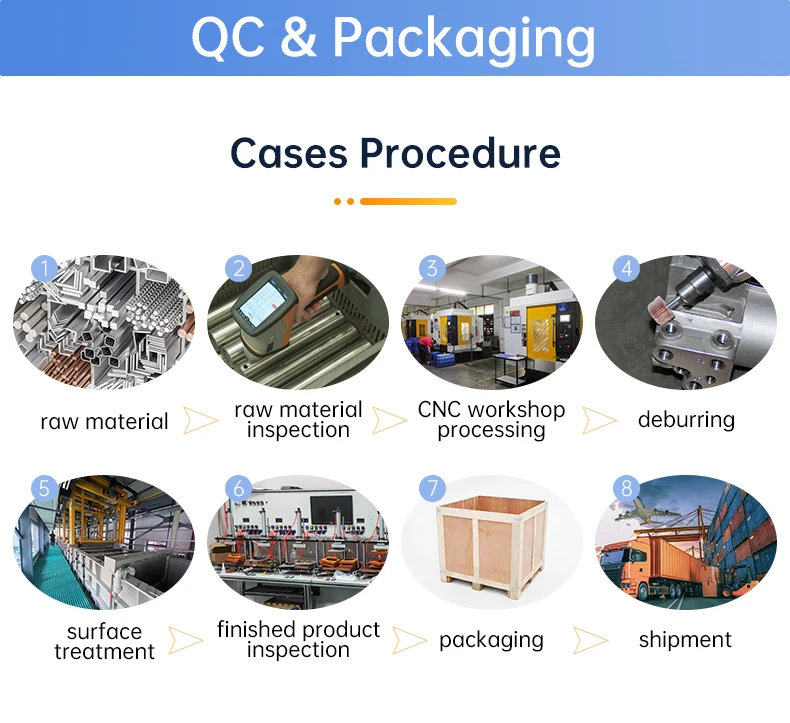

Overview | 1.Tagged price not actual price, requires actual quote;2.Buyers if you want to provide detailed drawings (CAD/DXF format, STP format or tolerance size) can contact our customer service, we can confirm the processing, please feel free to contact me; 3. Custom-ordered products do not support order cancellation | ||||||

Surface treatment | Plating, Brushing, Polishing, Anodizing, Sandblasting, Knurling, or customer's requirements | ||||||

Material Capacities | Metal: Aluminum alloy, stainless steel, brass, copper, tool steel, carbon steel, iron, Plastic: ABS, POM, PC(Poly Carbonate), PC+GF, PA(nylon), PA+GF, PMMA(acrylic), PEEK, PEI ,etc | ||||||

CNC processing scope | CNC 3-axis, 4-axis machining, CNC milling, CNC turning, CNC Lathe, High precision 5-Axis turning-milling combined machining | ||||||

Application | Optical instrument, Automotive, Electronic device, Digital communication, UAV, Aerospace, Bicycle, Pneumatic tools, Hydraulic, Automatic Mechanical, etc | ||||||

Tolerance: | |||||||

Delivery | DHL, FedEx, EMS, UPS, or customer's requirements | ||||||

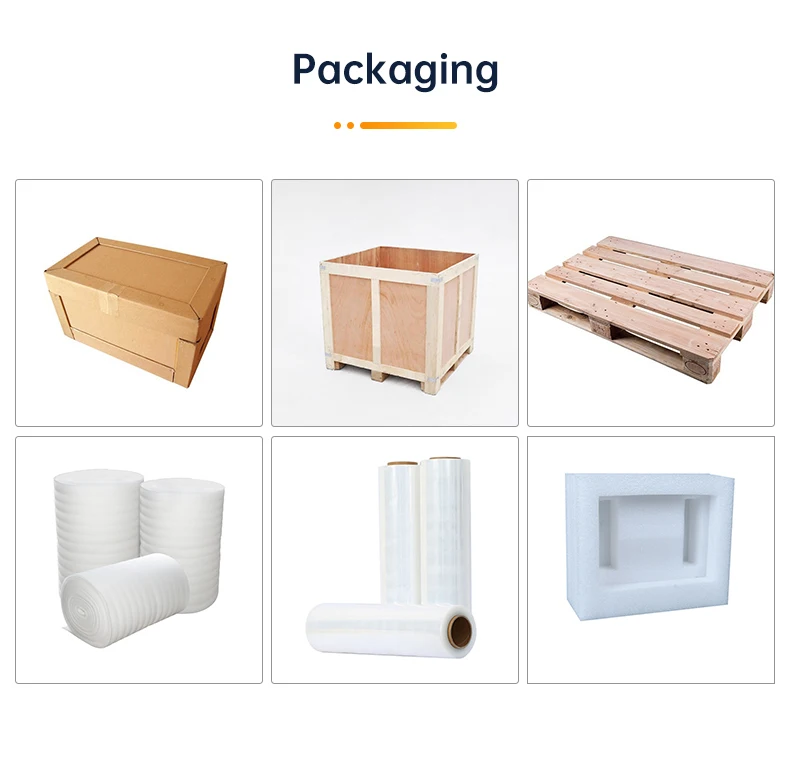

Package | Tissue paper, EPE, standard carton or plastic tray, sponge tray, cardboard tray, etc., can be customized according to customer requirements | ||||||

Our service

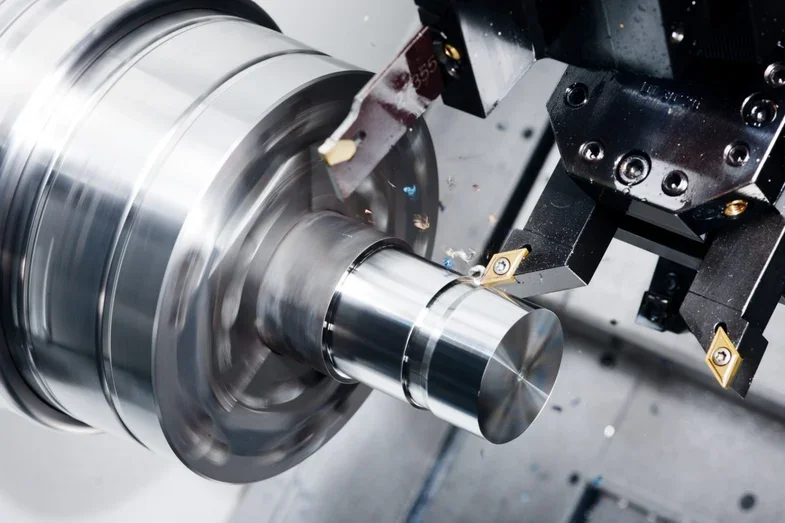

CNC Turning

CNC turning is a CNC process where a cutting tool, a typically non-rotating component of the lathe or turning center, removes

material from a rotating rigid material. This process produces different shapes and sizes depending on the turning operations

used.

material from a rotating rigid material. This process produces different shapes and sizes depending on the turning operations

used.

CNC Milling

It is a computer-controlled process involving using a cutting tool to remove part of a workpiece. The basic setup involves placing

the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece

into a finished product.

the workpiece on the machine’s table while the cutting tool/s attached to the spindle rotates and moves to shape the workpiece

into a finished product.

CNC Drilling

CNC drilling is a machining process involving rotating cutting tools for producing round holes in a stationary workpiece. The

purposes of drilling are aesthetic ones or for further accommodating of screws and bolts.

purposes of drilling are aesthetic ones or for further accommodating of screws and bolts.

Material Available | ||||||||

Aluminum | AL6061, AL6063, AL6082, AL7075, AL5052, A380, etc | |||||||

Stainless Steel | 303, 304, 304L, 316, 316L, 410, 420, 430, etc | |||||||

Steel | Mild Steel, Carbon Steel, 1018, 1035, 1045, 4140, 4340, 8620, XC38, XC48, E52100, Q235, SKD11, 35MF6Pb, 1214, 1215, etc | |||||||

Iron | A36,45#, 1213, etc | |||||||

Brass | HPb63, HPb62, HPb61, HPb59, H59,H68, H80, H90, etc | |||||||

Copper | C11000, C12000, C22000, C26000, C28000, C36000 | |||||||

Titanium Alloy | TC1, TC2, TC3,TC4, etc | |||||||

Plastic | ABS, PC, PP, PE, POM, Delrin, Nylon, Teflon, PEEK, PEI, etc | |||||||

Shipping & Delivery

FAQ

Q1:Where can I get product&price information?

Q2: How soon can I get samples?

Q3:How to enjoy the OEM services?

Q4:Can you make machining parts based on our samples?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical proposals

and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.