Китайская фабрика алюминиевая селфи-палка телескопическая анодированная селфи-Палка для телефона и

- Категории: >>>

- Поставщик: Shenzhen,Jincai,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product details

Key attributes Industry-specific attributes | ||||||||

CNC Machining or Not | Cnc Machining | |||||||

Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys | |||||||

Other attributes | ||||||||

Place of Origin | Guangdong, China | |||||||

Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Rapid Prototyping, Turning, Wire EDM | |||||||

Micro Machining or Not | Micro Machining | |||||||

Product Material | Plastic | |||||||

Model Number | OEM | |||||||

Brand Name | JINCAI | |||||||

Material | Aluminum | |||||||

Process | Turning | |||||||

Product name | Professional Precision Cnc Machining Parts | |||||||

Tolerance | 0.02mm -0.05mm | |||||||

Application | Industrial Equipment | |||||||

Service | One-stop Service | |||||||

Surface treatment | Passivation | |||||||

Materials Avaliable | Aluminum Plastic Metals Copper | |||||||

Machining equipment | 3/4/5 Axis Cnc Machining Centres | |||||||

QC Control | 100% Inspect Dimension | |||||||

Packaging and delivery | ||||||||

Packaging Details | wooden box, pallet, carton, PVC tray, PP bag as the customer required | |||||||

Port | Shenzhen | |||||||

Supply Ability | ||||||||

Supply Ability | 100000 Piece/Pieces per Month | |||||||

Product details | ||||||||

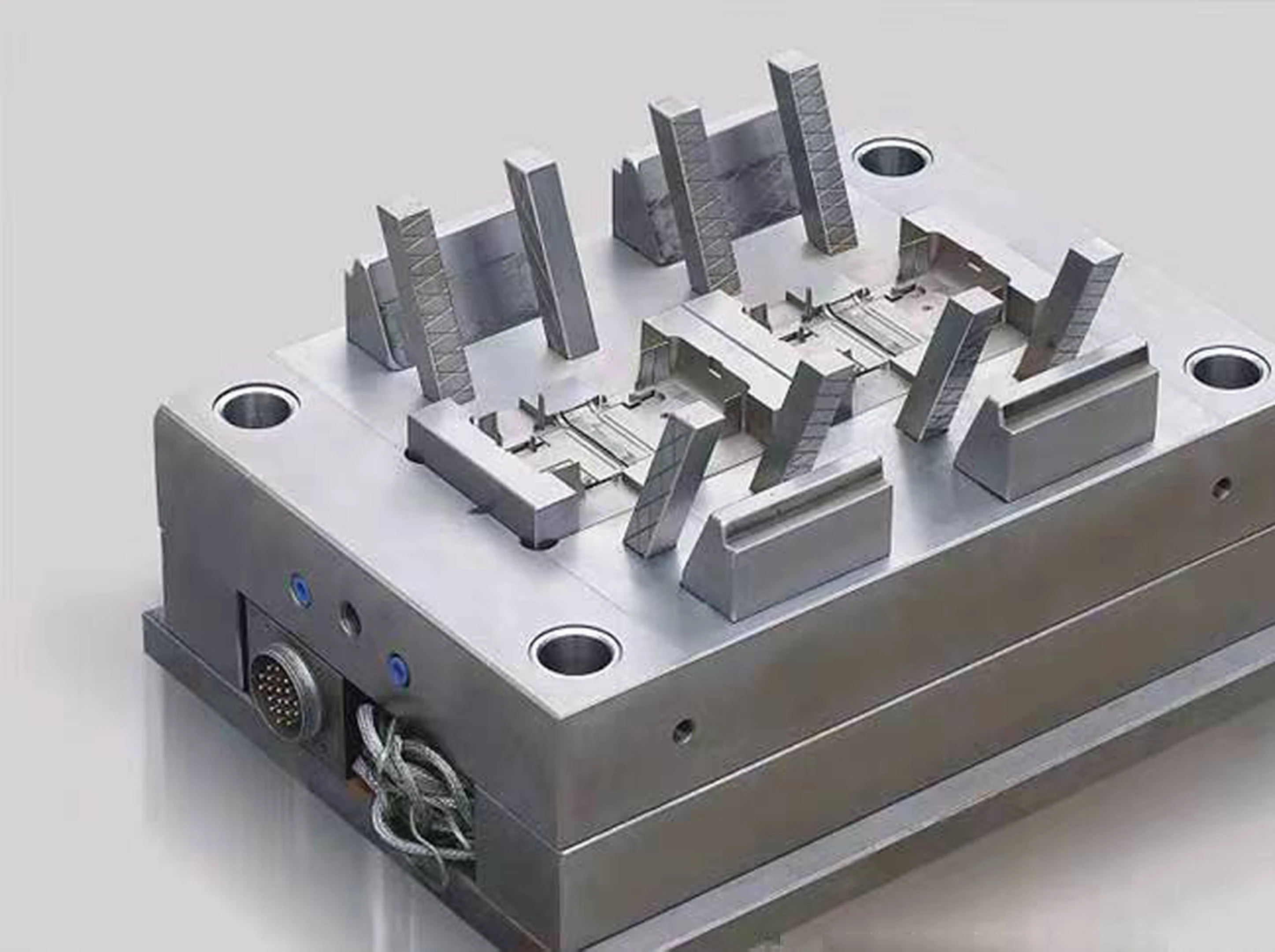

Customized precision 5 Axis CNC milling service machining metal block machined anodized aluminum parts | ||||||||

Product Description | ||||||||

Business Type | Factory / Manufacturer | |||||||

Service | CNC Machining | |||||||

Turning and Milling | ||||||||

CNC Turning | ||||||||

OEM Parts | ||||||||

Material | 1). Aluminum: AL 6061-T6, 6063, 7075-T etc | |||||||

2). Stainless steel: 303,304,316L, 17-4(SUS630) etc | ||||||||

3). Steel: 4140, Q235, Q345B,20#,45# etc. | ||||||||

4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc | ||||||||

5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc | ||||||||

6). Copper, bronze, Magnesium alloy, Delrin, POM,Acrylic, PC, etc. | ||||||||

Finish | Sandblasting, Anodize color, Blackenning, Zinc/Nickl Plating, Polish, | |||||||

Power coating, Passivation PVD, Titanium Plating, Electrogalvanizing, | ||||||||

electroplating chromium, electrophoresis, QPQ(Quench-Polish-Quench), | ||||||||

Electro Polishing,Chrome Plating, Knurl, Laser etch Logo, etc. | ||||||||

Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, | |||||||

Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | ||||||||

Drawing format | STEP,STP,GIS,CAD,PDF,DWG,DXF etc or samples. | |||||||

Tolerance | +/-0.01mm ~ +/-0.05mm | |||||||

Surface roughness | Ra 0.1~3.2 | |||||||

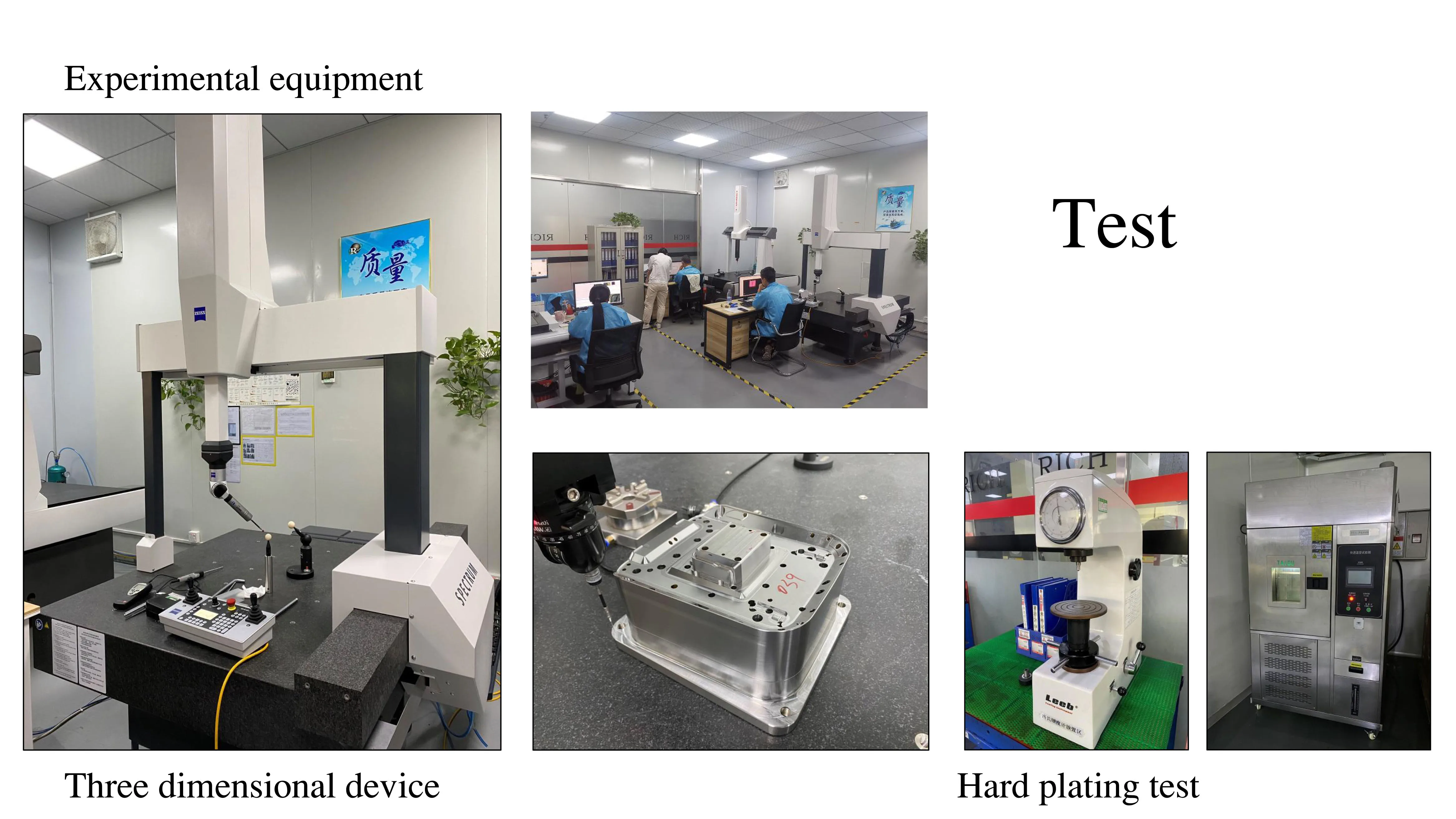

nspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM | |||||||

Depth Caliper Vernier, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | ||||||||

Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm | |||||||

CNC milling work range: 510mm*1020mm*500mm | ||||||||

Machining Equipment

Products Description

CNC turning part

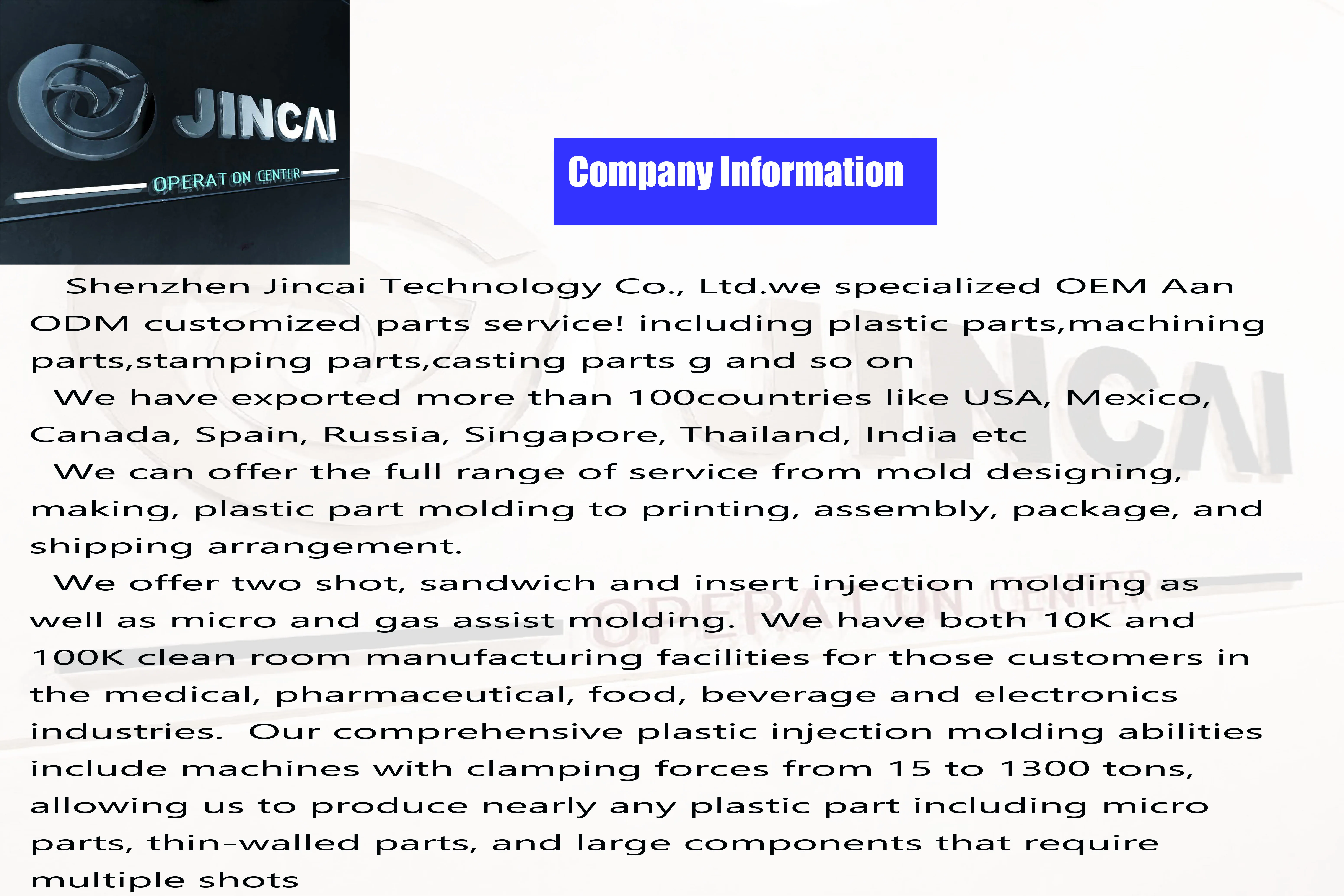

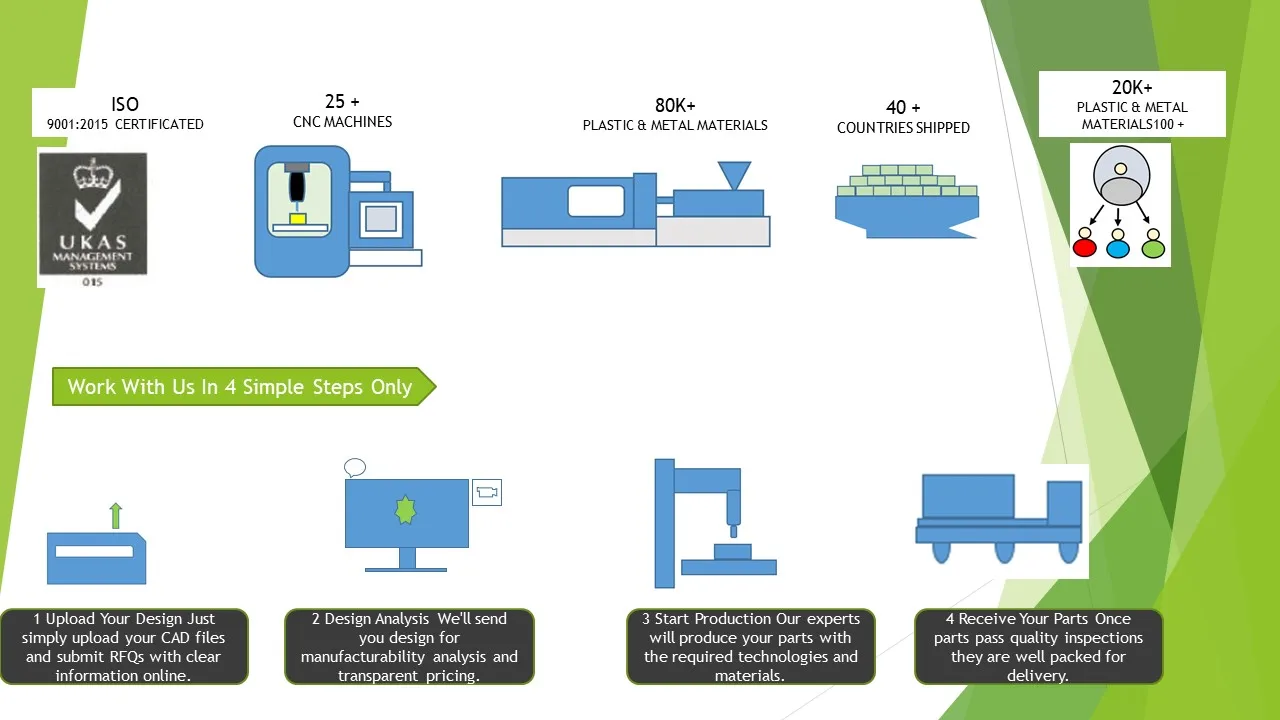

JINCAI provides custom cnc metal machining parts manufacturing services. We have complete toolmaking, parts designand production tools

Injection Molding

JINCAI provides complete mold manufacturing services. We have complete toolmaking, mold design, prototyping and production tools.3D printingSLA (Stereolithography)CNC Machining* Injection Molding

Contact us for free samples! !!

Company Profile

Customer Photos

Why Choose Us

Why Choose Us

Our company provides competitive price,good quality and stylish designs,our products are extensivelt used in Automobile Packaging and otherl industries. We have successfully set up relationship with about 30 companies in North American,Southeast Asia,Africa,Mid East andl other countries and regions,Our products are widely recognized and trusted by users and can meet continuously developing economic and social needs. If you are interested in some of our products.

FAQ

Q1:Where can I get product&price information?

A1:Send us e-mail , we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurement based on your samples to make drawings for machining parts making.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.