Абразивные полировальные материалы пескоструйная обработка черного/Зеленого Карбида Кремния

- Категории: >>>

- Поставщик: Shandong,Yafeite,Metal,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

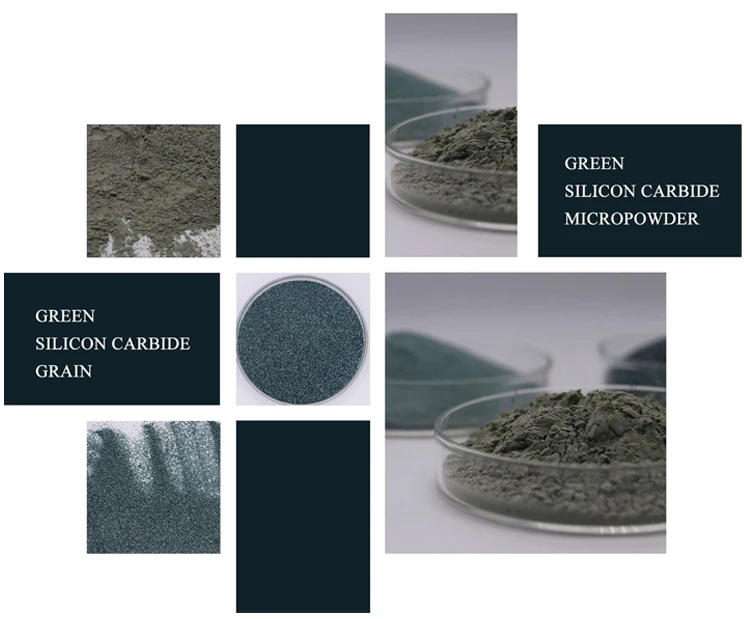

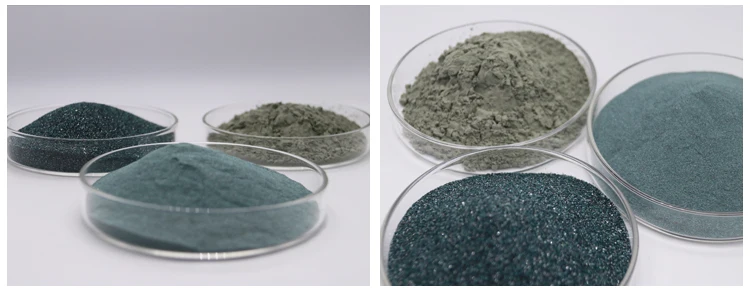

Green silicon carbide

The industrial production method of silicon carbide is to refine high-quality quartz sand and petroleum coke (salt needs to be added in the production of green silicon carbide) in a resistance furnace.There are two basic varieties of silicon carbide, black silicon carbide and green silicon carbide - SiC.

Product Paramenters

Granularity Distribution (um) | |||||

Type | Granularity | DO Below | D3 Below | D50 value | D94 Above |

Coarse | 20#-90# | / | / | / | / |

100#-180# | / | / | / | / | |

220# | / | / | / | / | |

Powder | GC #240 | 120 | 100 | 57±3.0 | 40 |

GC #280 | 110 | 80 | 48±3.0 | 33 | |

GC #320 | 93 | 70 | 40±2.5 | 27 | |

GC #360 | 80 | 60 | 35±2.0 | 23 | |

GC #400 | 70 | 53 | 30.0±2.0 | 20 | |

GC #600 | 50 | 38 | 20.0±1.5 | 13 | |

GC #800 | 30 | 20 | 14±1.0 | 9 | |

GC #1000 | 25 | 17.5 | 11.5±1.0 | 7 | |

GC #1200 | 20 | 16.5 | 9.5±0.8 | 6 | |

GC #1500 | 18 | 15 | 8.0±0.6 | 4.8 | |

GC #2000 | 16 | 13 | 6.7±0.6 | 4 | |

GC #2500 | 15 | 13 | 5.5±0.5 | 3 | |

GC #3000 | 13 | 11 | 4.0±0.5 | 2 | |

GC #4000 | 11 | 8 | 3.0±0.4 | 1.3 | |

GC #6000 | 8 | 5 | 2.0±0.4 | 0.8 |

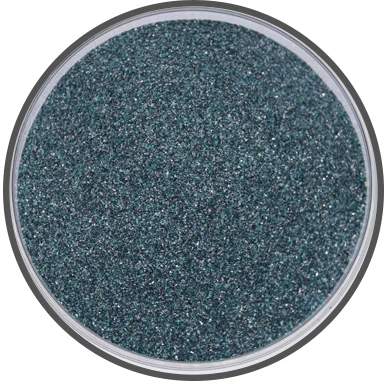

Macro /Grains | F Series | F16, F20, F22, F24. F30, F36, F40、F46, F54. F60, F70, F80, F90, F100F120, F150, F180, F220, F240 | |

Chemical composition | Sic | ≥99.5% | |

F.C | ≤0.2% | ||

Fe203 | ≤0.2% | ||

AL | 2PPM | ||

CA | 2PPM | ||

FE | 5PPM | ||

SiO2 | ≤0.4% | ||

magnet friction | 0.12% | ||

Physical Characteristics | PH | ≤7 | |

Hardness | 9-10 mohs | ||

Specific gravity | 3.2 g/ cm3 | ||

Bulk density | 0.75 - 1,82 g/cm3 | ||

Mohs hardness | 9.4 | ||

Melting point | 2600° (4712°F) | ||

Thermall conductivity | 210 btu/hr/ft2/in/°F at 400°F | ||

Thermal conductivity | 100 btu/hr/ft2/in/°F at16400°F | ||

Specific Gravity | 3.20 g/ cm3 | ||

Application | • Grinding wheel • Aviation field • Sandblasting • Coating • Polishing • Refractory industry • Composite and compound • Sawing ofsilicon, quartz and etc. | ||

Product Advantage

• high-temperature ceramics recrystallized silicon carbide.high-purity single crystals andsemiconductors

Our Advantages

-Abrasives

-Electronic product grinding

-Special ceramics

-Coating plastic modification

-Refractory products manufacturing

-Foam ceramic industry

-Solar silicon plate cutting

-Crystal cutting and grinding

-Environmental protection industries, etc.

Application

Company Profile

Shandong YAFIT Metal Products Co.,Ltd. is a world leading manufacturer of Refractory and abrasives for the foundry and refractory industries.Since our operations commenced with a mill in 1998, China Yafit Group has developed a unique supply chain with over

several series of production sites.Refractory annual output, such as white fused alumina, it arrive 200,000 tons per year. We have

30 processing furnaces, including 16 dumping furnaces and 14 fixed furnaces, accounting for half of China's total productivity.Strictly control the quality of product is a consistent core idea for Yafit Group 18years of business development process.We take care of every detail to provide focused and personalized customer service. We carry out commercial and technical visits periodically in order to promote the objectives and goals of our clients. Yafit Group is your reliable partner from offering consultation and reliable deliveries on time, through to our product quality.As the leader in technical development in

our industry we have pioneered many key advances and will continue to lead product development and innovation into the future

several series of production sites.Refractory annual output, such as white fused alumina, it arrive 200,000 tons per year. We have

30 processing furnaces, including 16 dumping furnaces and 14 fixed furnaces, accounting for half of China's total productivity.Strictly control the quality of product is a consistent core idea for Yafit Group 18years of business development process.We take care of every detail to provide focused and personalized customer service. We carry out commercial and technical visits periodically in order to promote the objectives and goals of our clients. Yafit Group is your reliable partner from offering consultation and reliable deliveries on time, through to our product quality.As the leader in technical development in

our industry we have pioneered many key advances and will continue to lead product development and innovation into the future

Product packaging

FAQ

1. who are we?

We are based in Shandong, China, start from 2006,sell to Western Europe(11.11%),Eastern Asia(11.11%),

We are based in Shandong, China, start from 2006,sell to Western Europe(11.11%),Eastern Asia(11.11%),

Mid East(11.11%),Oceania(11.11%),Africa(11.11%),Southeast Asia(11.11%),Eastern Europe(11.11%),South America(11.11%),North America(11.11%). There are total about 101-200 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,Japanese

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese,Japanese