Термокамень 200 м3 день Aac производственная линия автоматический Автоклавный газобетонный кирпич машина для производства

- Категории: >>>

- Поставщик: Guangxi,Hongfa,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Thermostone 200M3Day Aac Production Line Automatic Autoclaved Aerated Concrete Brick Making Machine Foam Concrete Block Machine

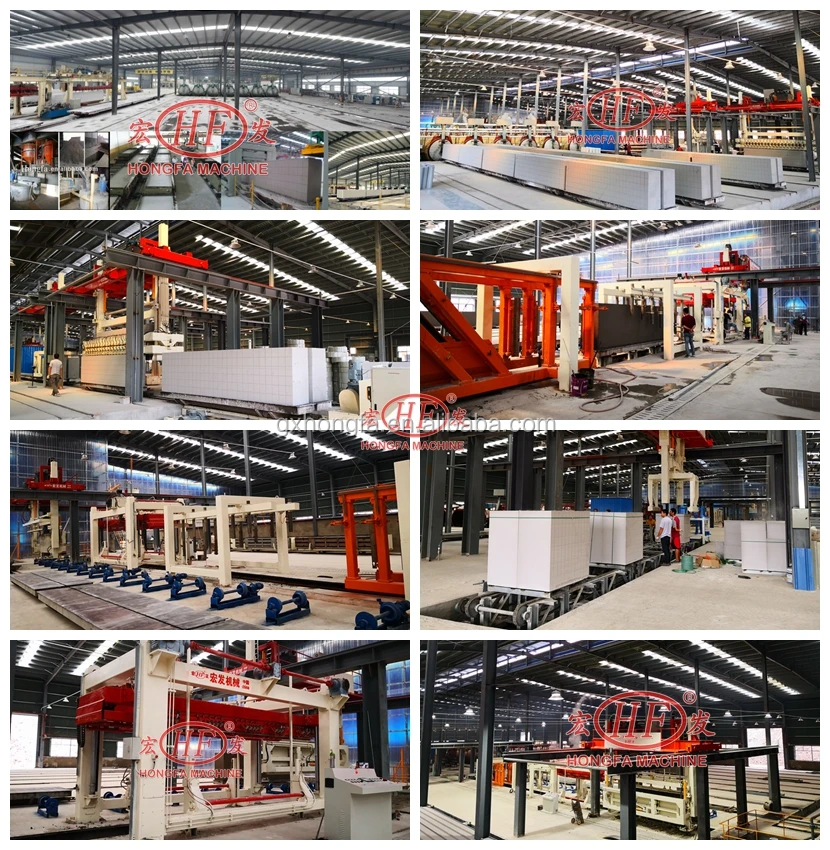

Hongfa AAC production line has a smooth process. The molds, side plates, and steam-curing cars each have independent circulation routes. All equipment does not cross operations, which greatly improves equipment operation efficiency and work safety.

• The control system adopts the internationally advanced centralized and segmented control method and adopts PLC control system. All processes are completed in the central control room and the ground division operation platform. The work realizes mechanized and automated production, with less labor and high production efficiency. Human errors cause little loss and the product qualification rate is high.

Aerated Block & Panel Production Line --- Equipment parts

I. Cutting Machine Parts:

Working principle of cutting machine: The tilting hanger turns the mould 90 degrees in the air , demoulds the blank and puts it on the cutting table together with the side plate . The blank on the cutting table is cut by the longitudinal cutting device through the motor and its own running . After completion and running at the pause position , the blank is cut horizontally by the cross cutting device when it is driven by the motor to the center of the blank . The cross cutting holder drops and cuts vertically from up to down until it is reset upward .

Technicla Parameter of Horizontal Cutting Machine:

| Size | Min Specing of Wries | Range of Oscillation | Diameter of Cutting Wire (mm) | Outline Dimensions (mm) | ||

| Length | Width | Height | ||||

| 4.2*1.2*0.6 | 10mm | 7.5 | φ0.6-1.0 | 5200 | 3200 | 3560 |

| 4.8*1.2*0.6 | 10mm | 7.5 | φ0.6-1.0 | 5900 | 3200 | 3560 |

| 6.0*1.2*0.6 | 10mm | 7.5 | φ0.6-1.0 | 7200 | 3200 | 3560 |

Technicla Parameter of Vetical Cutting Machine:

| Size | Min Specing of Wries | Diament of Cutting Wire (mm) | Outline Dimensions (mm) | |||

| for horizintal cutting | for side trimming | Length | Width | Height | ||

| 4.2*1.2*0.6 | 5mm | φ0.6-0.8 | φ0.8 | 5500 | 2860 | 2500 |

| 4.8*1.2*0.6 | 5mm | φ0.6-0.8 | φ0.8 | 5500 | 2860 | 2500 |

| 6.0*1.2*0.6 | 5mm | φ0.6-0.8 | φ0.8 | 6500 | 2860 | 2500 |

II. Pouring Mixer:

The pouring mixer is mainly to make measured the slurry . Ash and aluminum suspending liquid into mixing drum ,the pouring slurry after mixed will be poured into mould through discharge Butterfly valve to make maintenance, the machine adopts lelical blade in draft tube for mixing tyoe, it can make kinds of materials mixing uniformity effectively.

The parameter of pouring mixer:

| Mixing Type | Motor power | Mixing volume | Blade diameter | Blade speed |

| Draft tube | 30kw | 3.6 m3 | φ560mm | 560r/min |

| Draft tube | 37kw | 4.5 m3 | φ630mm | 560r/min |

III.Mould (For example 4.2m; 4.8m; 6m)

In the Aerated concrete block peoduction , the slurry mixed by pouring mixer pured into mould, after maintenance in curing room, it can cutting the aerated concrete green body.

Mould Parameter:

| Size (m) | Size of body(peeling-off size) (mm) | Maximum pverall size (mm) | ||||

| Length | Width | Height | Length | Width | Height | |

| 4.2*1.2*0.6 | 4200 | 1200 | 600 | 4720 | 1735 | 1078 |

| 4.8*1.2*0.6 | 4800 | 1200 | 600 | 5320 | 1735 | 1078 |

| 6.0*1.2*0.6 | 6000 | 1200 | 600 | 6550 | 1750 | 1085 |

Advatages of AAC block / alc panel

1.Light weight and high strength

The weight of ALC products is 1/3--1/10 of the traditional material department, which effectively reduces the weight of the buiding and improves the seismic resistance of the buiding.

2.Fire retardant

AAC products are A1 grade non-combustible materials, and the fire resistance limit of 100mm thick AAC wall can reach 4hours.

3.Green rnvironmental protection

The raw materials and finished products of AAC products are inorganic materials, which are non-toxic and harmless throughout the life cycle, and are truly green and environmentally frinedly new buiding materials.

4.Soud insulation and sound absorption

AAC products have the dual performance of sound insulation and sound absorption, and theri weighted sound insulation can rach 40-60dB when used as a wall, which fully meets the sound insulation requirments of buildings.

5.Precise dimensions

The error of high-quality AAC products is only ±1mm, which provides a reliable guarantee for high-precision and high-efficiency assembly construction.

6.Waterproof and impermeable

The inside of AAC products is closed and non-connected pores, and special construction technology and supporting materials are used to effectively prevent water penetration.

7.Thermal insulation

The dry thermal conductivity of AAC products is 0.055-0.17w/(m*k), which can efectively improve the energy saving level of buildings and reduce energy consumption compared with other wall materials.

8.Safe and durable

After autoclaving, the product has stable performance and good durabiblity.

keeping temperature

aerated concrete panel has many porous,the delivery hearting coefficient is 0.9-0.22W/(mk),the same as 1/4 or 1/5 of clay brick,so it is best materials now in the world. Also many kinds raw material,have lowest wasteMain Material:coal ash sand waste mine material coal stone,stone dust and other silicon materials.

General specification

L | W | H |

600 | 100 120 125 150 180 200 240 250 300 | 200 240 250 300

|

Size deviation

Item | Standard |

| |||||

High-class product(A) | Qualified product(B) |

| |||||

Allowed size deviation/ mm | Length | L | ±3 | ±4 |

| ||

Width | B | ±1 | ±2 |

| |||

Height | H | ±1 | ±2 |

| |||

The products reach the block requirements of grade 04~07 of GB11968-2006

Main Material

coal ash sand waste mine material coal stonestone dust and other silicon materials.

1. Product weight is according to 600kg/m3 to control.

2 .annual capacity 200,000M3.

3. set raw material proportion: cement 6.5%, raw lime 23%, flyash 68%, gypsum 3%, aluminum paste powder 350g/M3.

4. water and material rate 0.631

5. one mould product 2.88M3

6. Casting slurry cycle time 5-6 minutes, cut cycle time 5 minutes.

7.casting slurry temperature 38-42 degree

8 .body quiet stop. Time is 1.5-2.5housr, temperature 50-90 degree, after quiet stop body strength is 0.15-0.18Mpa

9 .Steam curing cycle time, come in and out autoclave about 0.5hour, steam curing cycle time about is 6 hours/1.6Mpa, total 6.5 hours

Packing: Naked packing or stretch film packing or according to customers' requirements

Delivery time: Within 30 days after receipt of deposit and moulds confirmation from buyer

1.Guarantee for one year and after sale service for whole life.To offer free design,free technology support and free machine maintenance trainning.

2.We will provide you with a set of spare parts for free!

Hongfa Machinery is your best choice

Brand and quality

We are a construction and building materials equipments manufacturer mainly produce all kinds of AAC block making machine,concrete mixing plant,mixer,concrete block making machine,concrete tile making machine and concrete pipe making machine etc. with more than 30 years experience and being the biggest manufacturer in China at present.All the products are conformity with the standard of the state, and gets the ISO9001-2000 Quality System certificate, also honored as "One of the Top Ten Famous Brands of Brick & Tile field in China" and other honors.

Hongfa Machinery's Honor

1.One of Top Ten Influential Brands in China Brick &Tile Industry

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

Exhibitions & cooperations

Hongfa, as a top brand enterprise in China, our products are also exported to Russia, Brazil, Thailand, Indonesia, Vietnam, Angola, Bangladesh, India, Australia, Sudan, etc., 132 countries and regions, deeply welcomed by clients from all around the world.

Hongfa Machinery Group Main Products :

Main products: Concrete mixing plant,mixer, concrete block making machine,concrete tile making machine and concrete pipe making machine .

Automatic Block Making:

QT12-15D QT12-15 QT10-15D QT10-15 QT9-15 QT8-15D

QT8-15B QT6-15D QT6-15C QT6-15B QT4-15D QT4-15C

QT4-15B QT4-20C QTJ4-25

Semi-automatic:

QTJ4-35B2 QTJ4-40B2

Semi-automatic egg-laying machine:

QTY4-30 QMJ4-45 QTJ2-45 JMQ-6A

Color Paver Color tile forming machine:

QT3-20 SMY8-150

HF-800 pipe-making machine HF-2000 pipe-making machine

Concrete Mixing Plant:

HZS25 HZS35 HZS50 HZS60 HZS series

AAC Block production line : 50000~300000M3/Year

FAQ

When you plan to purchase a certain machine, suggesting to take care below points:

1. What is the brand? ( Now a lot companies embezzle our brand, pls take note our prevention fake-mark.)

2. Does this brand has good reputation and sell well in the market?(we got good reputation and are the biggest supplier in China)

3. What is the materials they used? Manganese steel or A3 steel? (We use Manganese steel which stronger than A3 steel)

4.What is the guarantee period? ( We guarantee for one year)

5.The price cover to what equipment?( pls refer to our quotation list)

Please not hesitate to contact us if you are interested in any kinds of products.

Contact Information:

Foreign Trade Dept. :Emily Lee

WhatsApp/Tel:+8615177094840

Guangxi Hongfa Heavy Machinery Co., Ltd.

Wesite: www.gxhongfa.cn