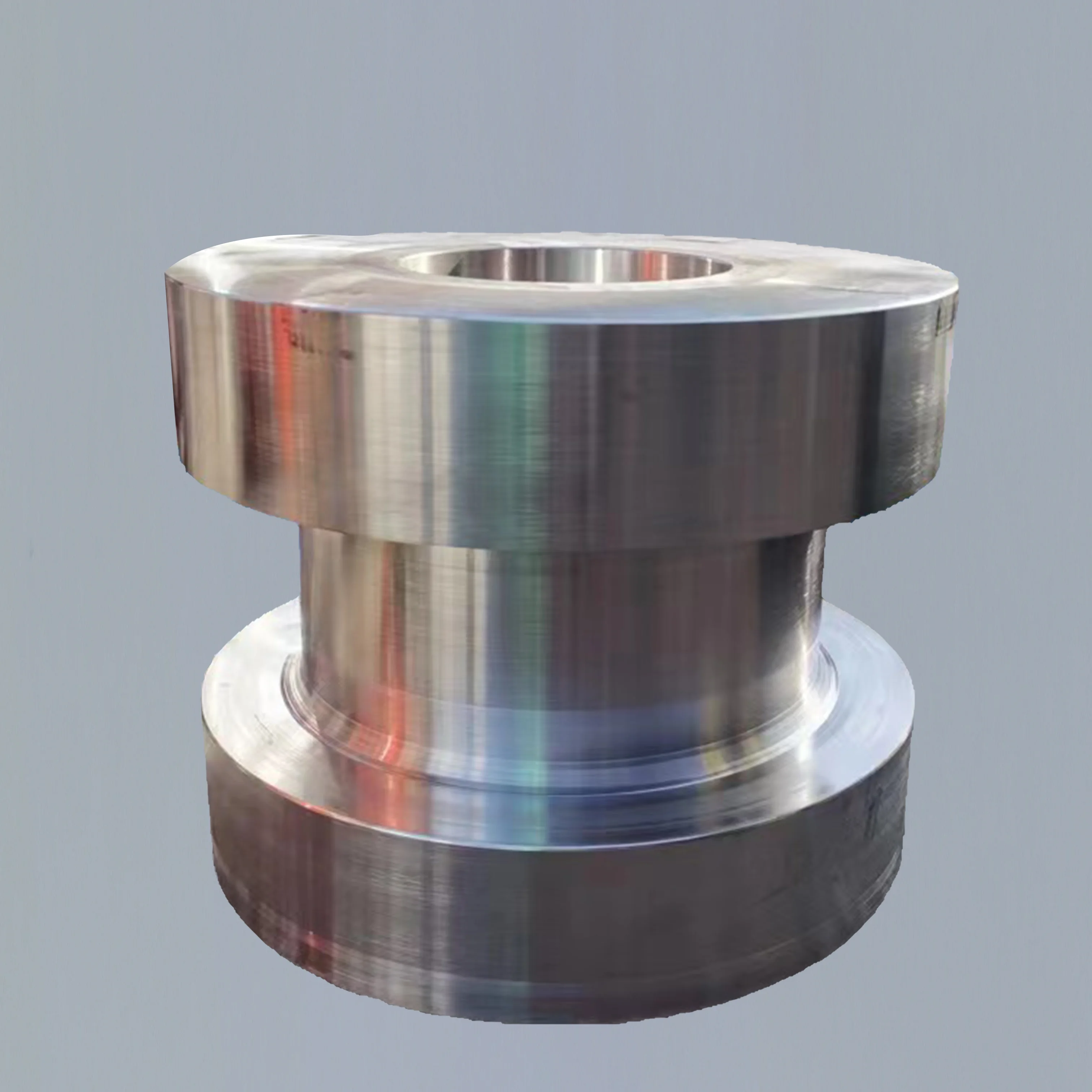

Индивидуальные кованые колесные прокладки из алюминиевого сплава адаптеры от 5x114 3 до 5x112 5x100 колесная гайка и болт 5x127

- Категории: >>>

- Поставщик: Shandong,Chengshuo,Metal,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

Brand | CS |

Item | Forging metal |

Materials | Stainless Steel, Aluminum, Carbon steel, Brass, copper |

Place of Origin | Shandong,China |

MOQ | 1pcs |

Tolerance | According to required |

Surface treatment | Zinc plated,Anodizing,Black oxide |

Material Certification | Provide after production |

Process | Forging |

Delivery | 4-7 working days |

Product packaging

Factory Show

Company Profile

FAQ

1. what is MOQ ?

1pcs

2. How many days is the delivery time?

About 4-7 working days

3. What materials are supported ?

Aluminum alloy,Stainless steel,Alloy Steel,Copper, Brass

4. Surface Treatment ?

Anodized, Oxide, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving Zn-plating, Ni-plating,Cr-plating, Tin-plating,copper-plating, the wreath oxygen resin spraying, the heat disposing,hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated,blue black zinc-plated,rust preventive oil, titanium alloy galvanized,silver plating, plastic, electroplating, anodizing etc.

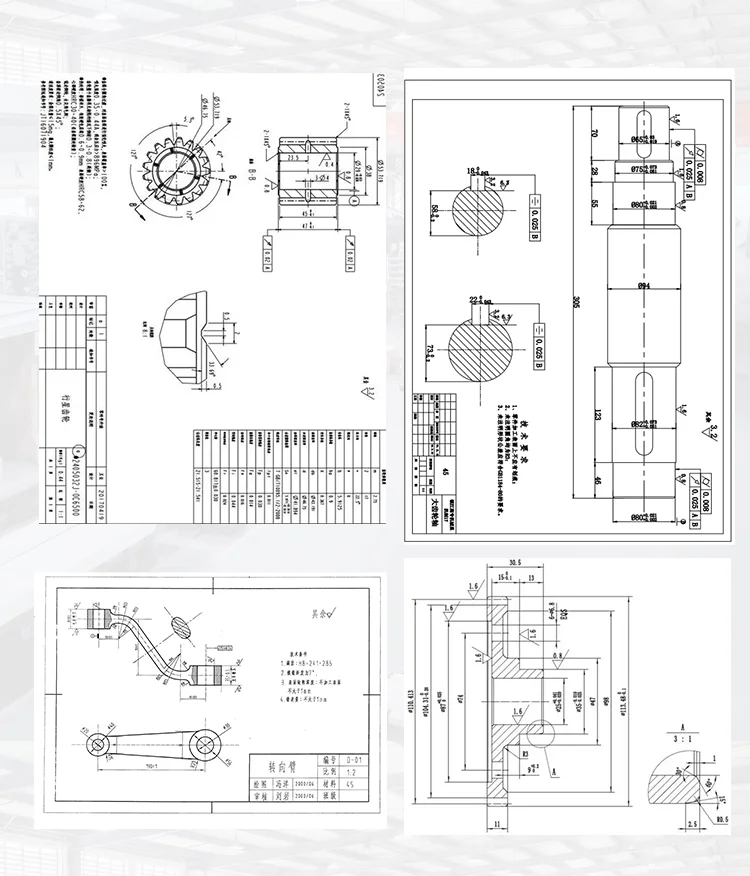

5. How To Customize?

Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.

1pcs

2. How many days is the delivery time?

About 4-7 working days

3. What materials are supported ?

Aluminum alloy,Stainless steel,Alloy Steel,Copper, Brass

4. Surface Treatment ?

Anodized, Oxide, Plating, Brushing, Polishing, Blackened, Powder coating, Sandblasting, Laser engraving Zn-plating, Ni-plating,Cr-plating, Tin-plating,copper-plating, the wreath oxygen resin spraying, the heat disposing,hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated,blue black zinc-plated,rust preventive oil, titanium alloy galvanized,silver plating, plastic, electroplating, anodizing etc.

5. How To Customize?

Drawing formation: PDF, CAD/DWG/DXF, IGS/STP etc.

In 2002, we started sheet metal processing services and participated in the supply chain of famous Chinese bus production. With our processing experience, we can help reduce production costs and modify designs, and you can enjoy our best service.

One-stop processing service

Our factory continues to expand the types of processing. Currently, it can complete sheet metal processing, CNC processing, forging processing, casting processing, etc., complete your parts production in one stop, saving your time.

Products Description

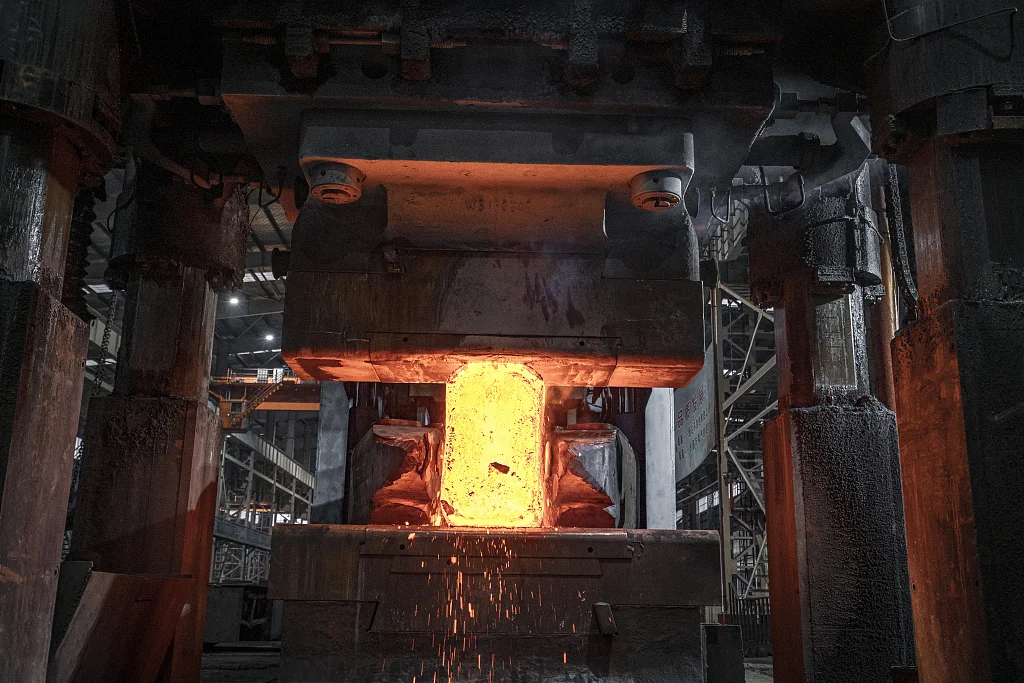

Forging Services

All customer drawings will be kept confidential.

Forging Services

We can complete free forging and die forging, and have 8000T and 4000T forging equipment, which can complete most of the customer's requirements. Other requirements will depend on the drawings and designs.

Free Forging

We provide open die forging services to manufacture large or complex shaped parts by heating and hammering metal billets. Open die forging allows processing in unrestricted spaces and can weigh up to a dozen tons. It is suitable for custom and small-batch production of high-strength, durable parts.

Die Forging

Our die forging service uses closed dies to apply pressure to the metal, suitable for mass production of dimensionally accurate parts. Die forging guarantees high production efficiency and consistent product quality, with weights ranging from several hundred kilograms to several tons. Suitable for mass production of high-precision and high-performance parts.

Machining and Q&T after forging

If the customer does not need machining, we can leave a machining allowance on the forged parts for the customer to process by themselves. The machining allowance is usually about 3mm, which can be based on the customer's requirements.

We can also provide machining services and Q&T service after forging, and the machining will be in accordance with the drawing requirements

We can also provide machining services and Q&T service after forging, and the machining will be in accordance with the drawing requirements

Customized services

We are good at designing and optimizing processing technology according to the specific needs of customers to maximize efficiency and quality. Whether it is single-piece customization or mass production, we can provide precise processing services.

From receiving an order to completing production, we take a variety of approaches to optimize the process, accurately cut materials, use induction heating technology, etc. to improve production efficiency and deliver quickly.

We strictly implement quality control standards in every processing link, and use high-precision measuring instruments to perform size inspection, surface finish inspection, etc. to ensure that every part meets customer requirements.

Product Paramenters

Forging Materials | Carbon Steel: AISI 1045, 1050 Alloy Steel: 4140, 4340, 42CrMo4 Stainless Steel: 304, 316, 17-4PH Aluminum Alloy: 6061, 7075 Titanium Alloy: Ti-6Al-4V Copper Alloy: Brass, Bronze Other materials can be customized upon request |

Forging Dimensions | According to drawings and design |

Tolerances | Dimensional Tolerance: ±0.5% to ±1.5% (Depending on process and requirements) Surface Roughness: Ra 3.2 to 12.5 microns (Depending on requirements) |

Heat Treatment | Annealing, Quenching, Tempering, Normalizing, etc. Hardness Range: HRC 30 to 65 (Depending on heat treatment method) |

Delivery Time | Production Lead Time: Typically 4 to 8 weeks (Depending on order volume and complexity) Rush Orders: Expedited services available, lead time subject to review |

Quality Control | Inspection Methods: Ultrasonic Testing (UT), Magnetic Particle Testing (MT), Radiographic Testing (RT), Dimensional Inspection,etc. |

Quantity Requirements | Minimum Order Quantity: 10 to 100 pieces (Depending on part size and complexity) Mass Production: Volume discounts available |

Packaging & Shipping | Packaging: Anti-rust paper, wooden crates, palletized Shipping Options: Sea, air, and land transport |

Quotation Validity | Typically valid for 30 days (Subject to market fluctuations) |

Payment Terms | Payment Schedule: Usually 30% deposit, 70% before shipment |

Sample display

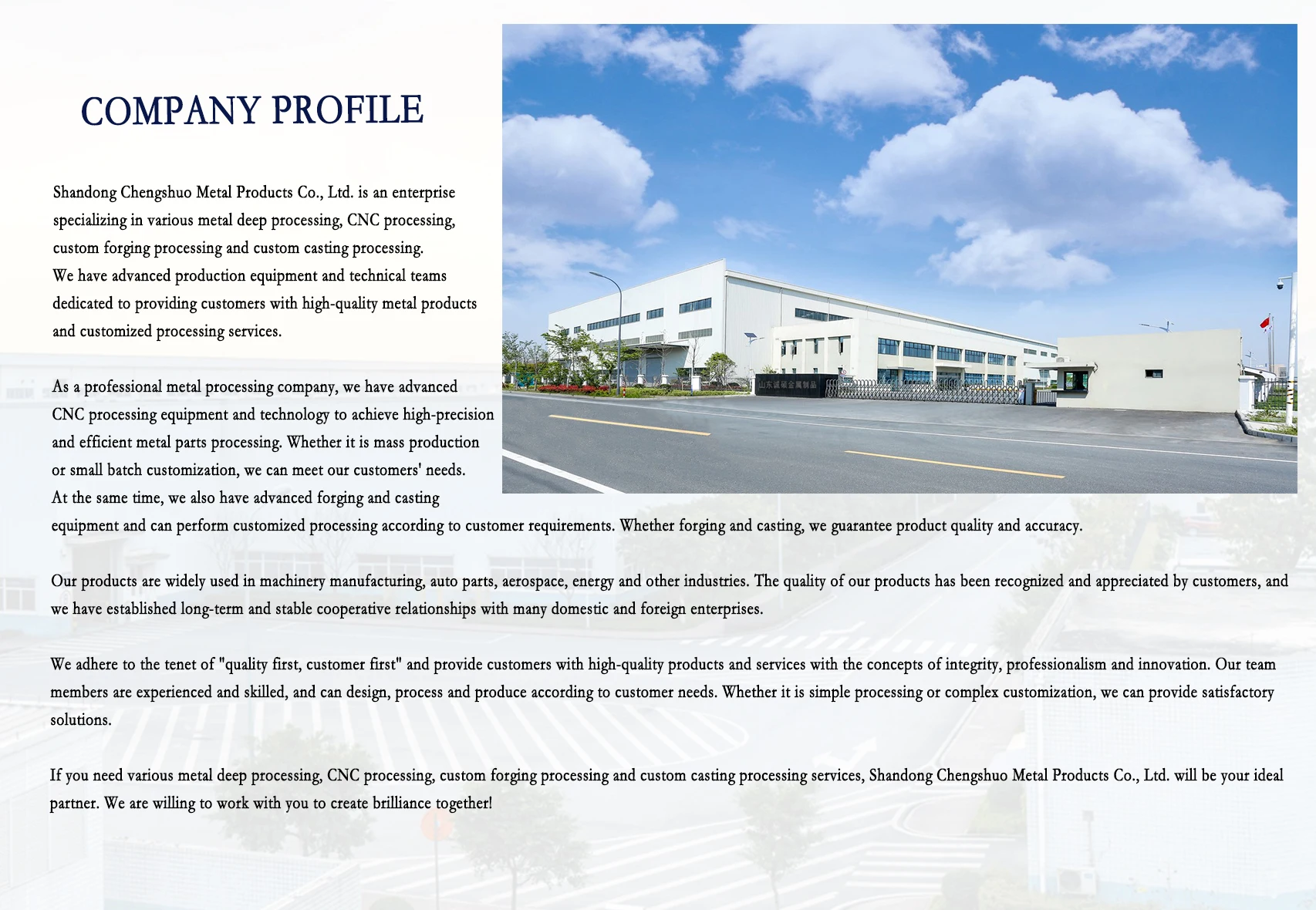

Company Profile

Shandong Chengshuo metal products co,ltd

We are a specialized metal processing company offering comprehensive one-stop services, with 22 years of industry experience. Our company is dedicated to providing a full range of metal processing solutions, including CNC precision machining, sheet metal fabrication, forging, and casting, tailored to meet diverse client needs.

With extensive expertise and advanced technology, we handle various materials and processes, offering complete solutions from design to manufacturing. Our CNC machining capabilities are robust, delivering high precision and efficiency for complex components. In sheet metal fabrication, we produce high-quality, reliable products, while our forging and casting processes ensure durable and standard-compliant metal goods.

For over two decades, we have upheld the principles of “quality first, integrity foremost,” earning the trust and support of our clients through stringent quality control and exceptional service. Moving forward, we are committed to continuous innovation and process improvement, providing superior products and services. We look forward to collaborating with partners across industries to achieve mutual success.

With extensive expertise and advanced technology, we handle various materials and processes, offering complete solutions from design to manufacturing. Our CNC machining capabilities are robust, delivering high precision and efficiency for complex components. In sheet metal fabrication, we produce high-quality, reliable products, while our forging and casting processes ensure durable and standard-compliant metal goods.

For over two decades, we have upheld the principles of “quality first, integrity foremost,” earning the trust and support of our clients through stringent quality control and exceptional service. Moving forward, we are committed to continuous innovation and process improvement, providing superior products and services. We look forward to collaborating with partners across industries to achieve mutual success.

Staff training

Activity Area

Meeting area

Sheet metal processing workshop

CNC workshop

Forging workshop

Powder coating workshop

Anodizing workshop

Casting workshop

FAQ

1. What is the difference between free forging and die forging?

Free forging is the processing of metal by hammering or press in an open environment without the use of dies, which is suitable for the production of large, customized parts. Die forging uses closed dies to form metal, which is suitable for mass production of high-precision, consistent-shaped parts.

2. What materials can be used for free forging and die forging?

Both free forging and die forging can process a variety of materials, including carbon steel, alloy steel, stainless steel, aluminum alloy, titanium alloy and copper alloy. The choice of material depends on the application needs and performance requirements of the final product.

3. Do the forged parts need to be processed later?

Usually, the forged parts need to be heat treated, machined or surface treated to achieve the final dimensional accuracy and performance requirements. These subsequent processes help to improve the hardness, strength and wear resistance of the parts. We can complete these processes.

4. What is the production cycle of forged parts?

In general, the production cycle of free forging and die forging is 4 to 8 weeks, depending on the order quantity, material procurement and processing complexity. If there is an urgent need, we can also provide expedited service.

5. Forged parts can undergo a variety of surface treatments, including heat treatment (such as annealing, quenching, tempering), sandblasting, polishing, coating, etc., to improve the performance and durability of the parts.

6. How to determine the appropriate forging process?

The selection of a suitable forging process depends on the size, shape, material and production quantity of the part. We will provide the most suitable forging process recommendations based on customer requirements and part characteristics.

Free forging is the processing of metal by hammering or press in an open environment without the use of dies, which is suitable for the production of large, customized parts. Die forging uses closed dies to form metal, which is suitable for mass production of high-precision, consistent-shaped parts.

2. What materials can be used for free forging and die forging?

Both free forging and die forging can process a variety of materials, including carbon steel, alloy steel, stainless steel, aluminum alloy, titanium alloy and copper alloy. The choice of material depends on the application needs and performance requirements of the final product.

3. Do the forged parts need to be processed later?

Usually, the forged parts need to be heat treated, machined or surface treated to achieve the final dimensional accuracy and performance requirements. These subsequent processes help to improve the hardness, strength and wear resistance of the parts. We can complete these processes.

4. What is the production cycle of forged parts?

In general, the production cycle of free forging and die forging is 4 to 8 weeks, depending on the order quantity, material procurement and processing complexity. If there is an urgent need, we can also provide expedited service.

5. Forged parts can undergo a variety of surface treatments, including heat treatment (such as annealing, quenching, tempering), sandblasting, polishing, coating, etc., to improve the performance and durability of the parts.

6. How to determine the appropriate forging process?

The selection of a suitable forging process depends on the size, shape, material and production quantity of the part. We will provide the most suitable forging process recommendations based on customer requirements and part characteristics.