Полностью автоматическая машина для дистилляции отработанного моторного масла/оборудование переработки

- Категории: >>>

- Поставщик: Chongqing,Nakin,Electromechanical,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Application

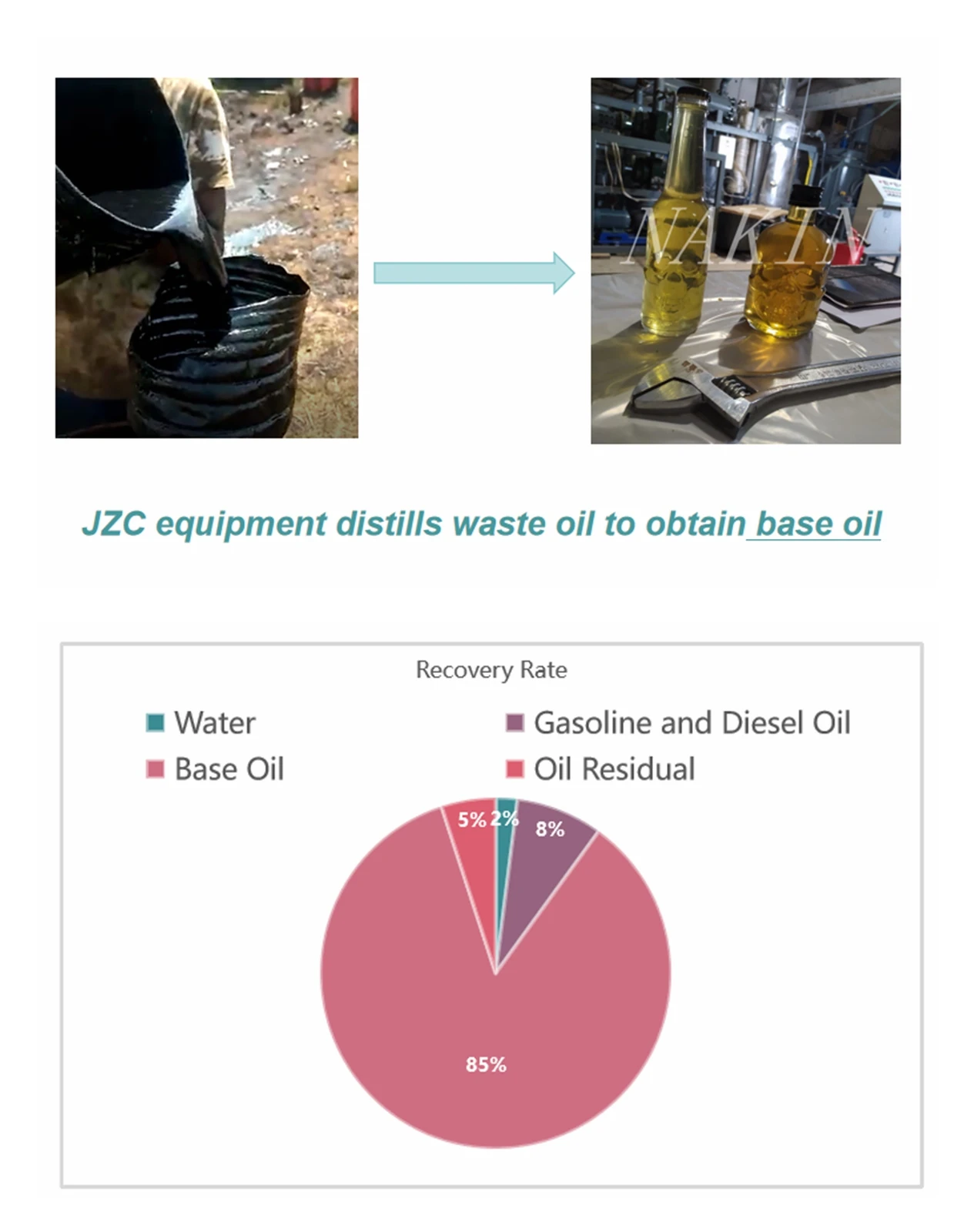

waste oil vacuum distilling machine (JZC waste oil distillation machine) is special for distilling and regenerating the black waste lube oil, including waste engine oil, lube oil, hydraulic oil, gear oil, dirty diesel oil, mixed oils etc. This equipment adopts physicochemical way to polymerize, passivity, absorb, eliminate impurities and harmful contaminations. JZC waste oil distillation machine heat the waste oil to (from 110℃ to 350℃) different temperature under high vacuum condition, making Hydrocarbon molecules break out, and re-order combination, forming diesel oil, lubricating base oil etc. JZC machine is very suitable for the small oil refinery company, also for the small oil company who want to make the oil by self.

Working Steps Of The Machine

Working Steps Of The Machine( Omitted version )

There are five steps from waste oil to base oil.

1.Use press paper filter device filter impurities in waste oil

2.The waste oil leads to the waste oil mixing tank, heat the waste oil to 60-80 ºC and then mix it with sodium hydroxide. When sodium hydroxide is mixed with waste oil, a chemical reaction will occur, flocculation and precipitation.

3.Use press paper filter device filter waste oil again, the waste oil then flows to the distillation tank.

4. Set the temperature, let the distillation tank heat to the set temperature, and distill out water vapor and oil vapor. The

distillation temperature reaches 80-110ºC, and water is distilled.The distillation temperature reaches 120-210ºC, and Gasoline and diesel is distilled. The distillation temperature reaches 220-290ºC, and light base oil is distilled. The distillation temperature reaches 300-350ºC, and heavy base oil (Viscosity≥SN150 ) is distilled.

5. The oil is then condensed through a cooler condenser,condensation from vapor state to liquid state. This step is actually the operation of employees opening different valves and pumps. There is no difficulty in operation. Emphasize that the machine comes with a collection tank that can separate different types of oil.

1.Use press paper filter device filter impurities in waste oil

2.The waste oil leads to the waste oil mixing tank, heat the waste oil to 60-80 ºC and then mix it with sodium hydroxide. When sodium hydroxide is mixed with waste oil, a chemical reaction will occur, flocculation and precipitation.

3.Use press paper filter device filter waste oil again, the waste oil then flows to the distillation tank.

4. Set the temperature, let the distillation tank heat to the set temperature, and distill out water vapor and oil vapor. The

distillation temperature reaches 80-110ºC, and water is distilled.The distillation temperature reaches 120-210ºC, and Gasoline and diesel is distilled. The distillation temperature reaches 220-290ºC, and light base oil is distilled. The distillation temperature reaches 300-350ºC, and heavy base oil (Viscosity≥SN150 ) is distilled.

5. The oil is then condensed through a cooler condenser,condensation from vapor state to liquid state. This step is actually the operation of employees opening different valves and pumps. There is no difficulty in operation. Emphasize that the machine comes with a collection tank that can separate different types of oil.

Features and Advantages

◆ Safety design, during the working process, raw materials oil is always flowing and flashing between the distillation tank and heating system, there is no any coking happen in the pipes and tanks, so the system is 100% safety, and long life time.

◆ There are optional ways to heat the oil, like the boiler way by using fuel, natural gas or coal. Also, if machine is small capacity, we can use the electric heating way.

◆ By using the high vacuum distilling way, so the distilling temperature is low, energy saving and safety.

◆ Using the special chemicals to catalyze the waste oil, which makes sure the final diesel oil, gasoline oil and base oil are good anti-oxidation with good color, there is no bad odor. The final oil can be storage for one year without color change and odor change.

◆ Oil cooler system adopts the SS304, which has the good heating exchange function, long life time.

◆ Environmental friendly, there is only 5-8% of the oil residual under the distilling kettle, which can be use as the boiler heavy fuel, so there is no pollution.

◆ The final oil is high purity; gasoline/diesel oil and lube base oil be loaded in different oil tanks.

◆ Machine design life is more than 20 years, long working life time.

◆ Easy operation, only 1 or 2 workers can operate the machine.

Most 3 abvious advantages of our JZC equipment compared with competitos

1. The warranty period of our equipment is 2 years, and other companies usually only have 1 year.

2.Distillation tank has insulation layer, which has energy-saving effect

3.The cooler is made of stainless steel, which has a longer life.

Oil Parameters After Treatment

Final Product | Ratio Percentages | Distillation Temperature | Vacuum Value | ||

Water | 2% | 80ºC-110ºC | -0.098 | ||

Gasoline and diesel | 8% | 120ºC-210ºC | 500Pa | ||

Light base oil | 40% | 220ºC-290ºC | 50-500 Pa | ||

Heavy base oil | 45% | 300ºC-350ºC | 50-500 Pa | ||

Oil Resicudal | 5% | ||||

Total | 100% | ||||

Detailed Photos

Project Show

Representative of key projects

Panamanian customers personally visited our customer's factory and obtained oil samples. After returning to Panama, he took the oil sample to the laboratory for testing and placed an order for our JZC equipment. He bought 3 sets JZC in total, and now he has become our agent in South Africa

Customer Visit Our Company

Product Packing

Company Profile

CHONGQING NAKIN ELECTROMECHANICAL CO.LTD. is a professional mechanism manufacturer (oil purifier) from Chongqing China.The company has a 3000 square meter production workshop with more than 40 staffs and engineers. The company is joint-stock high-tech enterprise, after ten years of development, company has grown into a comprehensive enterprise, engaging in vacuum oil purifier producing, filter element producing, and Imp&Exp trading. NAKIN oil purifier and filter are widely applied in projects of transformer substation, electric department, steel structure, bridge, auto, railway, aviation, chemicals, petroleum etc. The products are exported to more than 30 countries and areas, such as Europe, America, Middle East, Southeast Asia and so on. The product gets the good reputation from the dealer and end user.

FAQ

Q1. What are the heating methods of the machine?

A: The conventional heating method of JZC is electric heating. If you need to customize the burner heating mode, we can also customize it for you.

Q2. How about the Installation of the machine?

A: About installation, the installation of the machine is modular and sample.If we send engineer , buyer need to be responsible for engineer's round-trip airfare, visa, accommodation and his salary 100 dollars /day. With the installation instructions,buyer can also install by themselves. Our Engineers can talk with customers in English video to teach how to install and use the machine.Whether engineers are needed or not depends on the customers themselves.

Q3. What is your terms of payment?

A: Generally, we use T/T, 30% in advance, balance pay after the machine finish.

Q4. How about your delivery time?

A: Generally, JZC-1 (1 ton/day) need 35 workings days to finish. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you customized goods for us?

A: Yes, we can customized according to your flow requirements, the brand requirements of parts used in the machine........

Q6. If you have any inspection or test for your goods before delivery?

A: Yes, we do the inspection and test before finished goods.

Q7. Can we visit your factory?

A: Yes, we warmly welcome your visiting, and can pick up you at airport or train station.

A: The conventional heating method of JZC is electric heating. If you need to customize the burner heating mode, we can also customize it for you.

Q2. How about the Installation of the machine?

A: About installation, the installation of the machine is modular and sample.If we send engineer , buyer need to be responsible for engineer's round-trip airfare, visa, accommodation and his salary 100 dollars /day. With the installation instructions,buyer can also install by themselves. Our Engineers can talk with customers in English video to teach how to install and use the machine.Whether engineers are needed or not depends on the customers themselves.

Q3. What is your terms of payment?

A: Generally, we use T/T, 30% in advance, balance pay after the machine finish.

Q4. How about your delivery time?

A: Generally, JZC-1 (1 ton/day) need 35 workings days to finish. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you customized goods for us?

A: Yes, we can customized according to your flow requirements, the brand requirements of parts used in the machine........

Q6. If you have any inspection or test for your goods before delivery?

A: Yes, we do the inspection and test before finished goods.

Q7. Can we visit your factory?

A: Yes, we warmly welcome your visiting, and can pick up you at airport or train station.

Certifications

Contact Us