Дешевая установка для разделения газа воздуха 600 Нм 3/ч химическая очистки диоксида углерода фармацевтической

- Категории: >>>

- Поставщик: Wobo,Industrial,Group,Corp.

Поделиться:

Описание и отзывы

Характеристики

Cryogenic Air Separation Ultra-Pure Carbon Dioxide Equipment

Fast Delivery Air Separation Plant 99.9999%Purity User-Friendly Carbon Dioxide Generator For Fire Extinguishers

Product Description

Our cryogenic separation equipment is purpose-built to provide ultra-pure carbon dioxide, meeting the demanding specifications of diverse industries including healthcare, food and beverage, and industrial applications. By harnessing advanced cryogenic technology, our equipment guarantees efficient and dependable separation processes, resulting in the production of high-quality, ultra-pure carbon dioxide. Depending on the gas production capacity and carbon dioxide requirements, we employ a range of techniques such as ambient temperature molecular sieve purification, low-pressure circulation with cryogenic refrigeration, or medium-pressure air circulation combined with high and low-temperature expansion refrigeration. These processes enable us to achieve carbon dioxide purity levels surpassing 99.9999%, ensuring an exceptional standard of product for our customers' needs.

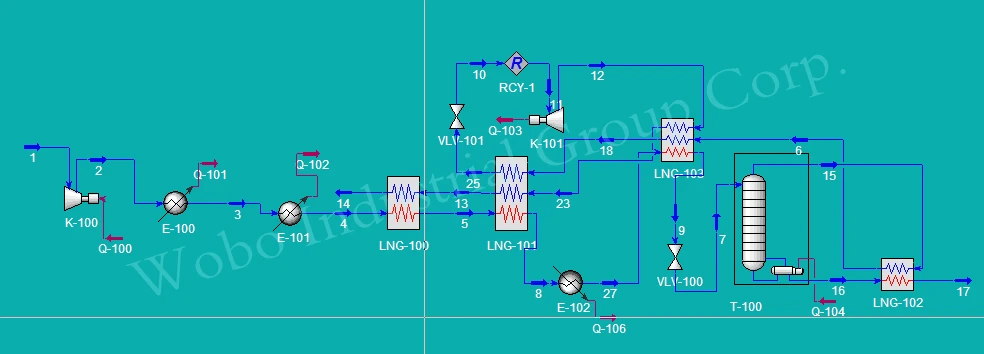

Process Description

The cryogenic air separation equipment for ultra-pure carbon dioxide employs a meticulous process to ensure the production of high-quality carbon dioxide with exceptional purity. The following steps outline the process description:

1. Intake and Compression: The air, containing carbon dioxide, is taken into the cryogenic air separation equipment and compressed to the desired pressure. This compression stage prepares the air for further processing.

2. Cooling and Liquefaction: The compressed air undergoes a series of cooling processes to lower its temperature. Cryogenic refrigeration systems are employed to achieve extremely low temperatures, causing the carbon dioxide to transition from a gas to a liquid state. The cooling and liquefaction stages enable the separation of carbon dioxide from other components present in the air mixture.

3. Separation and Purification: The cooled and liquefied air is then subjected to separation processes, which involve techniques such as ambient temperature molecular sieve purification. This purification method selectively removes impurities and contaminants, ensuring that the resulting carbon dioxide is of ultra-pure quality.

4. Medium-Pressure Air Circulation and Expansion: In certain cases, a medium-pressure air circulation technique combined with high and low-temperature expansion refrigeration is employed. This process involves circulating the air at a medium pressure and subjecting it to controlled temperature expansions. These expansions facilitate the liquefaction of carbon dioxide, enabling its separation from other components.

5. Quality Assurance: Throughout the process, stringent quality control measures are implemented to monitor and verify the purity levels of the produced carbon dioxide. Analytical techniques are utilized to ensure that the carbon dioxide meets or exceeds the required purity standards, often surpassing 99.9999% purity.

By utilizing advanced cryogenic technology, our cryogenic air separation equipment ensures the efficient and reliable separation of carbon dioxide, resulting in ultra-pure carbon dioxide output. The precise combination of compression, cooling, liquefaction, separation, and purification techniques guarantees the highest quality carbon dioxide for various industrial applications, meeting the stringent requirements of industries such as healthcare, food and beverage, and others that rely on ultra-pure carbon dioxide for their processes.

Product Parameter

Applicable Gas | CO2 | |||

Crafts | Abs | Cat+Abs | ||

O2 | <1 | <1 | ||

H2O | <1 | <1 | ||

CO | <1 | <1 | ||

H2 | <1 | <1 | ||

CH4 | —— | <1 | ||

VA | <0.005 | <0.005 | ||

VB | <0.5 | <0.5 | ||

RC | <0.005 | <0.005 | ||

Corg | <0.15 | <0.15 | ||

Ncorg | <1 | <1 | ||

* We can customize it according to your requirements. | ||||

Equipment Advantages

1. Superior Purity: Our cryogenic separation equipment excels in delivering ultra-pure carbon dioxide with exceptional levels of purity exceeding 99.9999%. This high purity is crucial for industries such as healthcare and food and beverage, where stringent specifications and quality standards are required. The advanced cryogenic technology employed in our equipment ensures that impurities and contaminants are effectively removed during the separation process, resulting in a product of superior purity.

2. Customized Solutions: Our equipment is designed to accommodate various liquid production capacities and specific carbon dioxide requirements. By employing techniques such as ambient temperature molecular sieve purification, low-pressure circulation with cryogenic refrigeration, or medium-pressure air circulation combined with high and low-temperature expansion refrigeration, we can tailor the separation process to meet the unique needs of different industries and applications. This versatility allows us to provide customized solutions that address the specific requirements of our customers.

3. Efficient and Reliable Operation: The cryogenic technology integrated into our equipment ensures efficient and dependable separation processes. The precise control and optimization of temperature, pressure, and circulation systems enable smooth and consistent production of ultra-pure carbon dioxide. Our equipment's reliable operation minimizes downtime, ensuring a continuous supply of high-quality carbon dioxide for uninterrupted manufacturing processes.

4. Compliance with Industry Standards: Our cryogenic separation equipment meets the demanding specifications of diverse industries, including healthcare, food and beverage, and industrial applications. The ultra-pure carbon dioxide produced by our equipment complies with stringent industry standards and regulations, ensuring that it is safe for use in critical applications. This compliance guarantees that our customers can rely on our equipment to meet the specific requirements of their respective industries.

5. Enhanced Product Quality and Safety: The high-quality and ultra-pure carbon dioxide generated by our equipment contribute to improved product quality and safety. In applications such as food and beverage processing, the use of ultra-pure carbon dioxide helps maintain the integrity, freshness, and flavor of the products. Additionally, the reliable removal of impurities during the separation process ensures the safety of carbon dioxide used in healthcare applications and other sensitive industries.

Applications & Solutions

1. Cleaning Process in Chip Manufacturing: Our cryogenic air separation equipment offers significant advantages for the cleaning process in chip manufacturing. The ultra-pure carbon dioxide produced by our equipment ensures effective and efficient removal of contaminants from the chip surfaces. The high purity of the carbon dioxide minimizes the risk of introducing additional impurities during the cleaning process, resulting in cleaner and more reliable chips. Furthermore, the precise control and consistency of the carbon dioxide supply from our equipment contribute to improved process repeatability and yield in chip manufacturing.

2. Support Gas for Immersion Lithography: Cryogenic air separation of ultra-pure carbon dioxide provides a reliable source of support gas for immersion lithography systems. In the semiconductor industry, immersion lithography is a crucial process that requires a highly pure and stable gas environment. Our equipment delivers ultra-pure carbon dioxide that meets the stringent requirements for support gas in immersion lithography machines. The exceptional purity and stability of the carbon dioxide enhance the precision and reliability of the lithographic processes, resulting in higher-quality patterns and improved performance of semiconductor devices.

3. Food and Beverage Industry: Ultra-pure carbon dioxide is utilized in the food and beverage industry for a range of applications. It is commonly used in carbonation processes to create carbonated beverages, ensuring precise and consistent levels of carbonation. Additionally, ultra-pure carbon dioxide is employed for modified atmosphere packaging (MAP) to extend the shelf life of perishable food products by inhibiting microbial growth and oxidative reactions. The high purity and reliability of cryogenic air separation equipment make it ideal for these critical applications in the food and beverage industry.

4. Pharmaceutical and Healthcare Industry: In the pharmaceutical and healthcare sectors, ultra-pure carbon dioxide is essential for various applications. It is used in pharmaceutical manufacturing processes, such as solvent extraction, where high-purity carbon dioxide acts as an environmentally friendly and efficient solvent. Carbon dioxide is also employed in medical gas mixtures for respiratory therapies, where the purity and consistency of the gas are of utmost importance for patient safety. Cryogenic air separation equipment ensures the production of ultra-pure carbon dioxide that meets the stringent requirements of these industries.

5. Chemical and Petrochemical Industry: The chemical and petrochemical industry utilizes ultra-pure carbon dioxide for a range of applications. Carbon dioxide is used as a solvent, a reactant in chemical synthesis, and as a process gas for stripping, pH control, and cooling. The high purity and reliability of cryogenic air separation equipment enable the production of ultra-pure carbon dioxide, ensuring the quality and effectiveness of these chemical processes.

6. Environmental and Renewable Energy Applications: Ultra-pure carbon dioxide produced by cryogenic air separation equipment has applications in environmental and renewable energy sectors. It is used in carbon capture and storage (CCS) technologies to capture and sequester carbon dioxide emissions from industrial processes, reducing greenhouse gas emissions and mitigating climate change. Additionally, ultra-pure carbon dioxide is utilized in enhanced oil recovery (EOR) techniques to extract additional oil reserves from existing wells. The purity and consistency of carbon dioxide produced by cryogenic air separation equipment are crucial for the success of these environmental and energy applications.

4. Pharmaceutical and Healthcare Industry: In the pharmaceutical and healthcare sectors, ultra-pure carbon dioxide is essential for various applications. It is used in pharmaceutical manufacturing processes, such as solvent extraction, where high-purity carbon dioxide acts as an environmentally friendly and efficient solvent. Carbon dioxide is also employed in medical gas mixtures for respiratory therapies, where the purity and consistency of the gas are of utmost importance for patient safety. Cryogenic air separation equipment ensures the production of ultra-pure carbon dioxide that meets the stringent requirements of these industries.

5. Chemical and Petrochemical Industry: The chemical and petrochemical industry utilizes ultra-pure carbon dioxide for a range of applications. Carbon dioxide is used as a solvent, a reactant in chemical synthesis, and as a process gas for stripping, pH control, and cooling. The high purity and reliability of cryogenic air separation equipment enable the production of ultra-pure carbon dioxide, ensuring the quality and effectiveness of these chemical processes.

6. Environmental and Renewable Energy Applications: Ultra-pure carbon dioxide produced by cryogenic air separation equipment has applications in environmental and renewable energy sectors. It is used in carbon capture and storage (CCS) technologies to capture and sequester carbon dioxide emissions from industrial processes, reducing greenhouse gas emissions and mitigating climate change. Additionally, ultra-pure carbon dioxide is utilized in enhanced oil recovery (EOR) techniques to extract additional oil reserves from existing wells. The purity and consistency of carbon dioxide produced by cryogenic air separation equipment are crucial for the success of these environmental and energy applications.

We supply all kinds of small and medium sized air separation equipment, nitrogen production equipment, oxygen production equipment and liquefaction equipment, etc. Cryo Chains will continue to develop and promote industrial applications and related products to help you improve production efficiency.In addition, Cryo Chains will also provide a range of industrial services, for your business to provide full support.

Project Case

Related Products

Похожие товары

Генератор жидкого азота с низким уровнем шума

63 999,00-69 999,00 $

Портативный генератор кислорода-решение для подачи кислорода в любое время и любом месте

32 000,00-35 000,00 $

High Productivity Air Separation Plant Nitrogen

104 000,00-105 000,00 $