Абразивный диск коричневый корунд WA белый оксид алюминия шлифовальный круг плоская чашка

- Категории: >>>

- Поставщик: Henan,Saisu,Diamond,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

Corundum grinding wheel

Made of corundum, it has high hardness, good toughness and beautiful appearance. *It is suitable for grinding metal materials with medium strength and high tensile strength. *Such as ordinary carbon steel, alloy steel, malleable cast iron, hard bronze, etc.

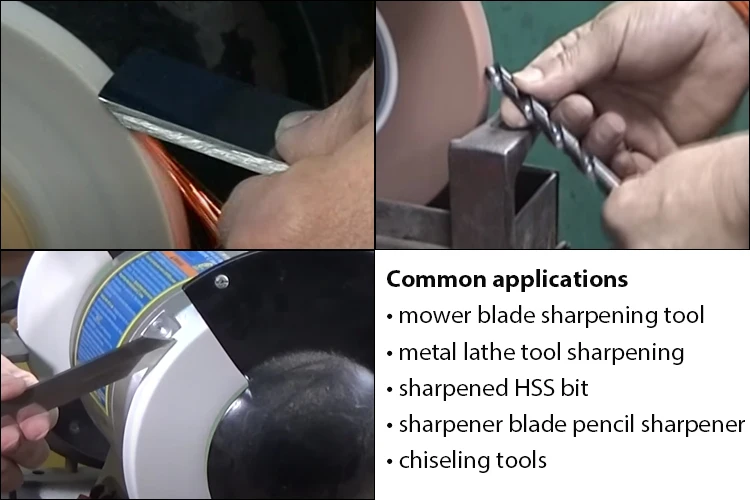

Product Features.

1. It can grind tools quickly and without burrs. 2. For workbench and floor machine. The grinding wheel is balanced and canoperate

normally.

3. It has uniform and closely bonded particles, which is suitable for providing a smooth and professional appearance.

Alumina Grinding Wheel,High hardness, abrasive grains are easily broken, sharp edges and corners, good cutting

performance, low grinding heat, etc. It is suitable for the grinding of steel with hard materials and strong heat sensitivity.

Such as the grinding of hardened steel, high carbon steel, general high speed steel, alloy steel, etc. Mainly used for grinding

and forming waste of tools, cutting tools, dies, gears, threads, thin-walled parts, etc

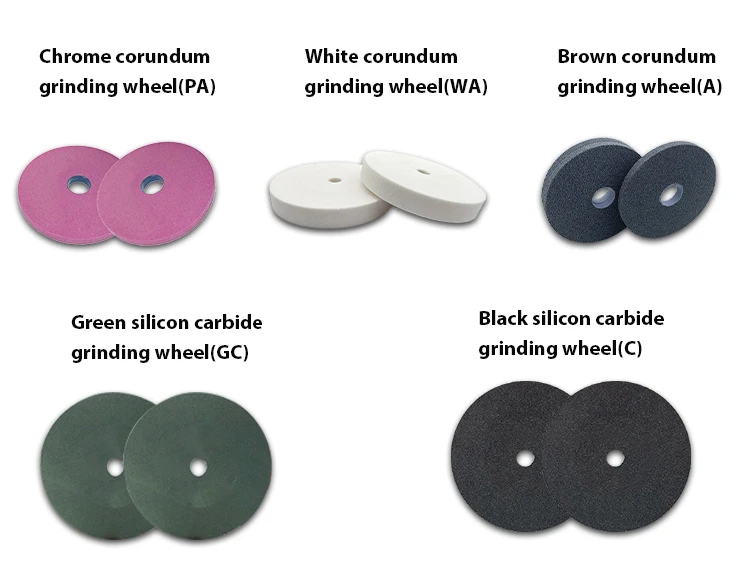

Small knowledge of material usage:

1. Brown fused alumina (A): suitable for carbon steel, alloy steel, malleable cast iron, hard bronze, etc.

2. White corundum (WA):Suitable for grinding thread grinding materials such as hardened steel, alloy steel, high-speed steel, high-carbon steel, etc.

3. Chrome corundum (PA): suitable for internal grinding of cutting tools, measuring tools, instrument threads, tool steel, stainless steel, quenched workpieces, tool grinding, etc.

4. Green silicon carbide (GC): suitable for hard and brittle materials such as cemented carbide, optical glass, ceramics, gems, and agate.

5. Black silicon carbide (C): suitable for cast iron, brass, aluminum, rubber, leather, wood, stone, refractory, etc.

| Coarse sandmaterial | alumina | | | | ||

| Item size | 200mmX25mmX31.75mm | | | | ||

| Compatible devices | Grinding machine | | | | ||

| Coarse sand type | medium | | | | ||

Safety several work description:

1. Select the grinding wheel with the spindle revolution of the grinder. Please check the grinding wheel before installation.Do not use it if any cracks or damages are found

2.The clearance between the inner hole of the grinding wheel and the spindle should not be too tight, which is generally controlled between 0.05~0.10 mm. When tightening the

nut, do not tighten it too tightly

3, The shield used by the grinder should cover at least half of the diameter of the grinding wheel

4. After the grinder is started, it must be idled for at least 2 minutes. During idling, the operator should stand in a safe

position, and it is strictly forbidden to stand in front of the grinding wheel or in the tangent direction

5. The rotation direction of the grinder should be correct, so that the grinding debris can only fly downward from the grinding wheel. Grinding is carried out after the grinder rotates smoothly. If the grinder runout is obvious, it should be stopped in time for dressing

6, The initial grinding can not be too hard, in order to avoid uneven grinding wheel force and accidents. Two people are not allowed to sharpen a knife on the same grinding wheel at the same time

7. It is strictly prohibited to use side grinding to avoid grinding wheel crushing. Do not grind copper, lead, wood and other things to prevent the grinding wheel from impingement

8, The sharpening time is long tool, should be timely cooling, to prevent hot hand

9. Regularly trim the surface balance of the grinding wheel. Keep it properly after use, do not knock against it, keep grinding wheel dry

10. always wear personal protective equipment, mask, eye mask, work cap, etc 11. Follow the instructions

Company Profile

China Sai su Diamond Tools Co..Ltd. is committed to providing customers with diamond roller Dresser abrasive tools&wheelsdiamond/CBN wheels tools for grinding,cutting,turning,milling,To provide customers with a one-stop grinding serviceOur customers find good applications in CNC forming gear grinding machine,bearing,special grinding machine, ordinary grinding machine,metalworking,AutomotiveStoneGlassesgemstonesIndustrial ceramic, oil & Gas drilling and Constructions industries. In these industriesour products are performing well on long lifetimehigh-efficiency and lessunit-cost.

Customer Reviews

Why Choose Us

Team

Professional team to give you an excellent shopping experience 1 to 1 professional service professional design docking First line workers

SERVICE

Sample and good after-sales service one year warr-anty Reply message timely Short delivery cycle professional export experience

FACTORY

We have rich experience in the production of diamond products, including various diamond dressers, grinding wheels and many grinding products etc

OEM&ODM

Products can be customized according to your requ-irements.Customized drawings free of charge ; Free logo design;Free packaging design;Design customi-zed products; free design drawing

Certifications

Exhibition

Packing & Delivery

Похожие товары

Алмазный шлифовальный диск для гранита 105 мм 115 мм 125 мм

US $5.00-$15.00

4-дюймовый режущий диск

US $0.10-$1.00

Параллельный Алмазный/CBN шлифовальный круг

US $16.00-$17.00

Алмазный шлифовальный диск для гранита 105 мм 115 мм 125 мм

US $5.00-$15.00