Автоматический самоочищающийся фильтр для системы рециркуляции воды эпоксидированный резиновый

- Категории: >>>

- Поставщик: Haian,Jci,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Products Description

AFM Filter is a new type of self-cleaning strainer independently developed by Shanghai Jiucheng company with our own interlectual property. It is designed for continuous online filtration to remove impurities on the outer surface of filter screen via highly-efficient mechani- cal scrapping. AFM Filter is mainly designed for middle- and high-viscosity filtration and the impurities with a certain hardness, with the precision range being 50-1500μm. Featuring precise filtration can effectively remove impurities from the surface of filtering screens, thus removing more impurities with high efficiency. It applies to the filtration of water and various viscous liquids.

Traditional filters easily get blocked when used to filtrating viscous materials and soft impuri- ties. For this reason, large-sized filters are usually selected or manual cleaning is frequently conducted, resulting in heavy investment, heavy work and serious waste of materials. Such problems can be easily solved by AFM Filter with advanced self-cleaning mode. It can regu- larly maintain cleanness of filtering screens and expel waste fluid containing high-concentra- tion impurities, thus reducing waste of materials. It has evident advantages and higher efficiency in filtrating poor-quality water and viscous materials such as adhesive, resin, poly- mer, coatings and grease.

Shanghai JCI owns full series of scraping self-cleaning filters, which falls into 4 subseries. AFE series, motor-driven external scraping; AFC series, pneumatic-driven internal scraping; AFM series, motor-driven internal scraping, AFB series, motor-driven internal brushing. AF Filters apply to different occasions and can fulfill customers’ various demands for mechanical self-cleaning filtration(AFC&AFE&AFB as shown in details).

Traditional filters easily get blocked when used to filtrating viscous materials and soft impuri- ties. For this reason, large-sized filters are usually selected or manual cleaning is frequently conducted, resulting in heavy investment, heavy work and serious waste of materials. Such problems can be easily solved by AFM Filter with advanced self-cleaning mode. It can regu- larly maintain cleanness of filtering screens and expel waste fluid containing high-concentra- tion impurities, thus reducing waste of materials. It has evident advantages and higher efficiency in filtrating poor-quality water and viscous materials such as adhesive, resin, poly- mer, coatings and grease.

Shanghai JCI owns full series of scraping self-cleaning filters, which falls into 4 subseries. AFE series, motor-driven external scraping; AFC series, pneumatic-driven internal scraping; AFM series, motor-driven internal scraping, AFB series, motor-driven internal brushing. AF Filters apply to different occasions and can fulfill customers’ various demands for mechanical self-cleaning filtration(AFC&AFE&AFB as shown in details).

Specification

Applicable liquid | Water and viscous liquid (<800000cps), impurity content <1000ppm |

Filtration accuracy | 50μm |

Standard design pressure rating | 1.OMPa, higher pressure can be customized |

High design temperature | 0-260℃ (depending on the seals) |

Single filter area | 0.14-1.45 ㎡ |

Cleaning pressure difference | 0.05MPa |

Differential pressure transmitter | Differential pressure transmitter or differential pressure switch |

Geared motor | 180w, three-phase,380V protection grade lP55; worm gear reducer |

lmport and export connection standards | Flange, HG20592-2009 (standard design), HG20615-2009 (compatible with ANSIB16.5) |

Filter element type material | V-shaped wedge net, material 304/316L/2205/titanium |

Shell wetted material | SS304/316L/2205/CS |

Scraper material | Alloy steel/PTFE |

Shell sealing material | NBR nitrile rubber(standard)VITON (FKM) fluorine rubber |

Public supply requirements | Pneumatic ball valve, protection grade lP65 |

Public supply requirements | 380V AC,0.4-0.6MPa clean and dry compressed air |

The main parameters and dimensions of the equipment:

Filter model No. | AFM14 | AFM28 | AFM42 | AFM77 | AFM116 | AFM145 |

Filter area(m2) | 0.14 | 0.28 | 0.42 | 0.77 | 1.16 | 1.45 |

Inlet and outlet size | DN20-DN50 | DN50 - DN80 | DN50 - DN100 | DN65 - DN100 | DN80 - DN125 | DN100 - DN150 |

Discharging outlet size | DN40 | DN40 | DN50 | DN50 | DN50 | DN50 |

Cylinder diameter(mm) | 273 | 273 | 273 | 460 | 550 | 550 |

Working principle

[Filter status]

The liquid flows in from the inlet, and the scraper with compensation is attached to the outer surface of the filter in a

tangential manner. The liquid flows inward from the outer surface of the filter through the filter, the impurities are trapped on the outer surface, and the liquid flows out from the outlet; as time goes by, the impurities Gradually increase, the pressure difference rises, and the filter screen is cleaned according to the set pressure difference or regularly.

[Cleaning state]

The motor drives the scraper to perform a horizontal rotation to clean the filter screen. When the scraper rotates, the impurities are scraped (peeled off) by the scraper and flow along the filter screen to the bottom of the filter, and the impurities are deposited in the dirt collection chamber. Each cleaning consists of several strokes. After the surface of the filter screen is cleaned, the filtering capacity is restored. Normally filter during cleaning without interruption of flow.

[Sewage state]

After multiple cleaning cycles, the impurities have accumulated to a sufficient amount, and the drain valve is opened regularly to discharge the waste liquid with high concentration of impurities. If necessary, it can also be recycled.

The liquid flows in from the inlet, and the scraper with compensation is attached to the outer surface of the filter in a

tangential manner. The liquid flows inward from the outer surface of the filter through the filter, the impurities are trapped on the outer surface, and the liquid flows out from the outlet; as time goes by, the impurities Gradually increase, the pressure difference rises, and the filter screen is cleaned according to the set pressure difference or regularly.

[Cleaning state]

The motor drives the scraper to perform a horizontal rotation to clean the filter screen. When the scraper rotates, the impurities are scraped (peeled off) by the scraper and flow along the filter screen to the bottom of the filter, and the impurities are deposited in the dirt collection chamber. Each cleaning consists of several strokes. After the surface of the filter screen is cleaned, the filtering capacity is restored. Normally filter during cleaning without interruption of flow.

[Sewage state]

After multiple cleaning cycles, the impurities have accumulated to a sufficient amount, and the drain valve is opened regularly to discharge the waste liquid with high concentration of impurities. If necessary, it can also be recycled.

Application

* Applicable fields: Petrochemical, fine chemical, grease, water treatment, papermaking, etc.

* Applicable liquid types: Resin, paint, ploymer, adhesive, citric acid, fermentation broth, chitosan, cosmetics, agarose(gel),silicone resin solution, soap, sorbitol, sterodi, grain syrup, wet department of additives, pigments, lubricants, rubber,ethanol, mixed oie, edible oil, high temperature oil, fruit juice, diesel, etc.

* Applicable liquid types: Resin, paint, ploymer, adhesive, citric acid, fermentation broth, chitosan, cosmetics, agarose(gel),silicone resin solution, soap, sorbitol, sterodi, grain syrup, wet department of additives, pigments, lubricants, rubber,ethanol, mixed oie, edible oil, high temperature oil, fruit juice, diesel, etc.

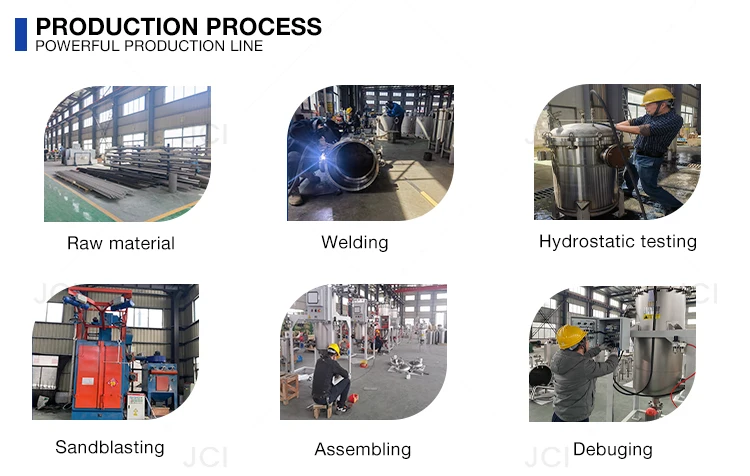

Production Process

Our Advantages

■ Horizontal rotary scraping, scraping off the impurities directly, is good at filtering middle- and high-viscosity filtration and the impurities with a certain hardness;

■ Simple structure, easy distuffing; after removing the scraper, easy to take out the filter screen and clean the inside;

■ Automatic operation, continuous online filtration, to end up the heavy filter screen replacement and cleaning work;

■ Do not produce disposable filter material, saving consumables costs and environmental costs;

■ Small filtration pressure loss, stable flowrate, energy saving .

■ Sealed filtration, preventing dangerous material leakage, is advantageous to the safe production and the staff health; ■ Discharge waste liquid with high impuries concentration can be recycled, to reduce the loss of high-value materials; ■ A variety of advanced control systems are optional, powerful, efficient and reliable;

■ A variety of advanced control systems are optional, powerful, efficient and reliable; selection of world-renowned brands of components, high reliability, low costs.

■ Simple structure, easy distuffing; after removing the scraper, easy to take out the filter screen and clean the inside;

■ Automatic operation, continuous online filtration, to end up the heavy filter screen replacement and cleaning work;

■ Do not produce disposable filter material, saving consumables costs and environmental costs;

■ Small filtration pressure loss, stable flowrate, energy saving .

■ Sealed filtration, preventing dangerous material leakage, is advantageous to the safe production and the staff health; ■ Discharge waste liquid with high impuries concentration can be recycled, to reduce the loss of high-value materials; ■ A variety of advanced control systems are optional, powerful, efficient and reliable;

■ A variety of advanced control systems are optional, powerful, efficient and reliable; selection of world-renowned brands of components, high reliability, low costs.

Related Products

Company Information

Shanghai JCI is a leading design and manufacturing company in the filtration industry, specializing in high-performance filtration equipment, especially in the field of self-cleaning filtration occupies an important position.Founded in 2014, the company is headquartered in Shanghai, with two production bases in Hai 'an, Jiangsu Province and Taiwan,China, and agents in Russia, the United States, Singapore, South Korea and other places. In March 2021, the company signed an investment and investment agreement with Jiangsu Haian City Government, and officially moved the factory to Nantong Haian in August of the same year. At present, the company has more than 5000 plants, the company currently has more than 40 patents, more than 2 invention patents, of which the company's self-developed self-cleaning and drying slag system fundamentally solves the pain points that have plagued the filtration industry for many years, and has been widely recognized by many customers and the industry.With excellent technical strength, exquisite product quality and excellent service system, JCI has won the trust and praise of many customers. At present, JCI has served more than 25 of the world's top 500 enterprises. In the future, Jiu Cheng will, as always, provide customers with better quality products and services to repay the support and trust of customers.