Титан цирконий гафний Ванадий ниобий тантал молибден вольфрамовая часть специальная обработка металла с

- Категории: >>>

- Поставщик: Qingdao,Huarui,Hardware,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Titanium,Zirconium, Hafnium, Vanadium, Niobium, Tantalum, Molybdenum,Tungsten Part Special Metal CNC Machining

| Material | Aluminum, Stainless steel, Copper,Bronze,iron Titanium,Zirconium, Hafnium, Vanadium, Niobium, Tantalum, Molybdenum,Tungsten |

| Size or shape | According to customer drawings or requests |

| Service | Sheet Metal Fabrication / CNC Machining / Metal cabinets&enclosure&box / Laser Cutting Service / Steel Bracket / Stamping Parts, etc. |

| Surface treatment | Anodizing,Polishing,Zinc Plating, Nickel Plating, Chrome Plating, Powder Coating, E-coating,blacken Ect. |

| Drawing accepted | CAD, PDF, SOLIDWORKS, STP, STEP, IGS, etc. |

| MOQ | 1PCS |

| Service mode | OEM or ODM |

| Certification | ISO 9001 |

| Feature | Focus on high end market products |

| Processing procedure | Laser cutting, cnc punching, cnc bending, riveting, welding, polishing, assembly |

| Package | Inner pearl button,wooden case,or customized. |

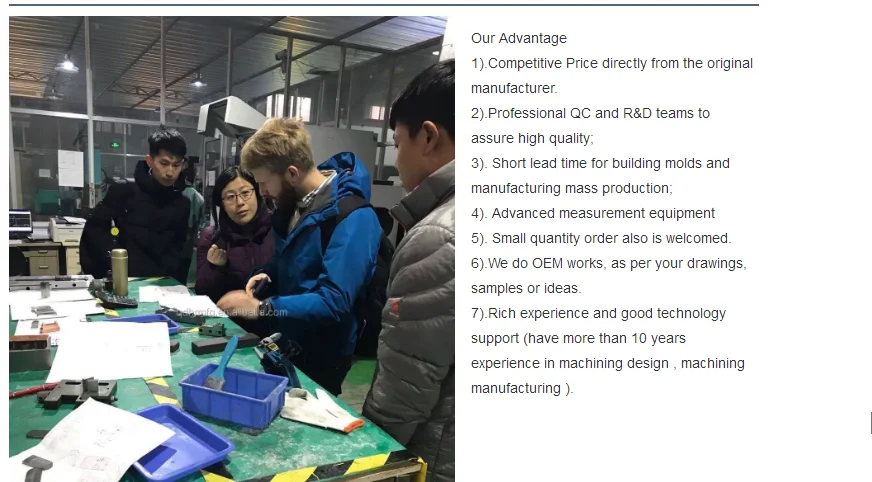

Introduction: - Introduce the topic of custom precision aluminum CNC turning machining parts. - Highlight the importance and relevance of these parts in various industries.

Body: 1. Definition and Explanation - Define custom precision aluminum CNC turning machining parts.

- Explain their significance in manufacturing processes, particularly in achieving high accuracy and quality.

2. Applications - Discuss the

wide range of industries that utilize these parts, such as aerospace, automotive, electronics, and medical. - Highlight specific examples or case studies to demonstrate their effectiveness in different applications.

3. Advantages - Outline the advantages of using custom precision aluminum CNC turning machining parts over other alternatives. - Enhanced precision: Discuss how these parts can achieve tight tolerances and intricate designs with minimal errors. - Durability: Emphasize the strength and longevity offered by aluminum material for various applications. - Cost-effectiveness: Explain how efficient production processes contribute to cost savings for manufacturers.

4. Manufacturing Process - Provide a brief overview of the steps involved in producing custom precision aluminum CNC turning machining parts.

- Material selection: Discuss why aluminum is commonly chosen for its desirable properties like lightweight yet sturdy nature. - Computer Numerical

Control (CNC) programming: Explain how computerized instructions guide machines to perform precise cutting operations on raw materials. - Turning process: Describe how lathes rotate workpieces while cutting tools shape them into desired forms. 5. Quality Assurance - Address the

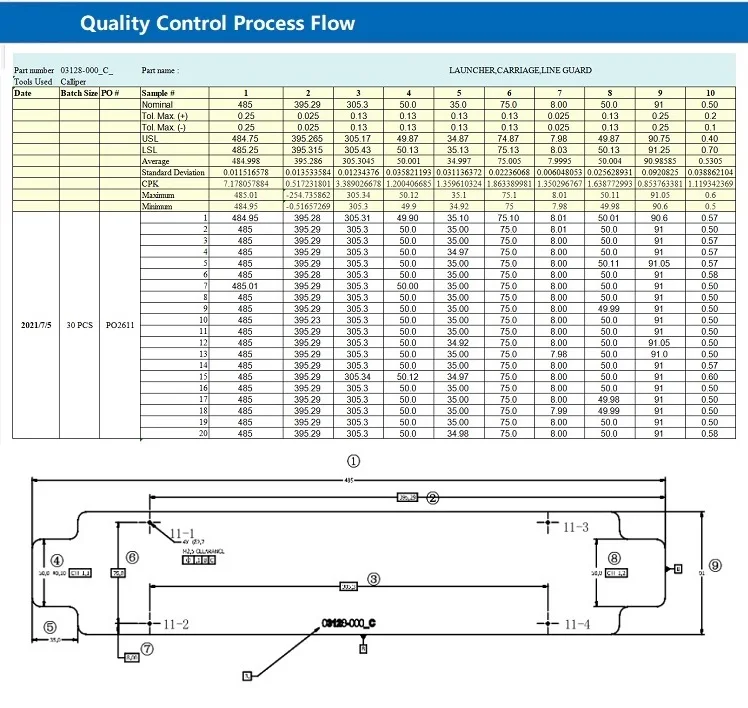

importance of quality control measures throughout the manufacturing process to ensure accurate dimensions and specifications are met consistently.

Q: ARE YOU TRADING COMPANY OR MANUFACTURER ?

A: We are factory.

Q: HOW LONG IS YOUR DELIVERY TIME?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: DO YOU PROVIDE SAMPLES ? IS IT FREE OR EXTRA ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: WHAT IS YOUR TERMS OF PAYMENT ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: