Массовая обработка водонепроницаемые Запчасти для часов сменные инструменты ремонта все стальные ручки и двойные

- Категории: >>>

- Поставщик: Shenzhen,Flourish,Legend,Limited

Поделиться:

Описание и отзывы

Характеристики

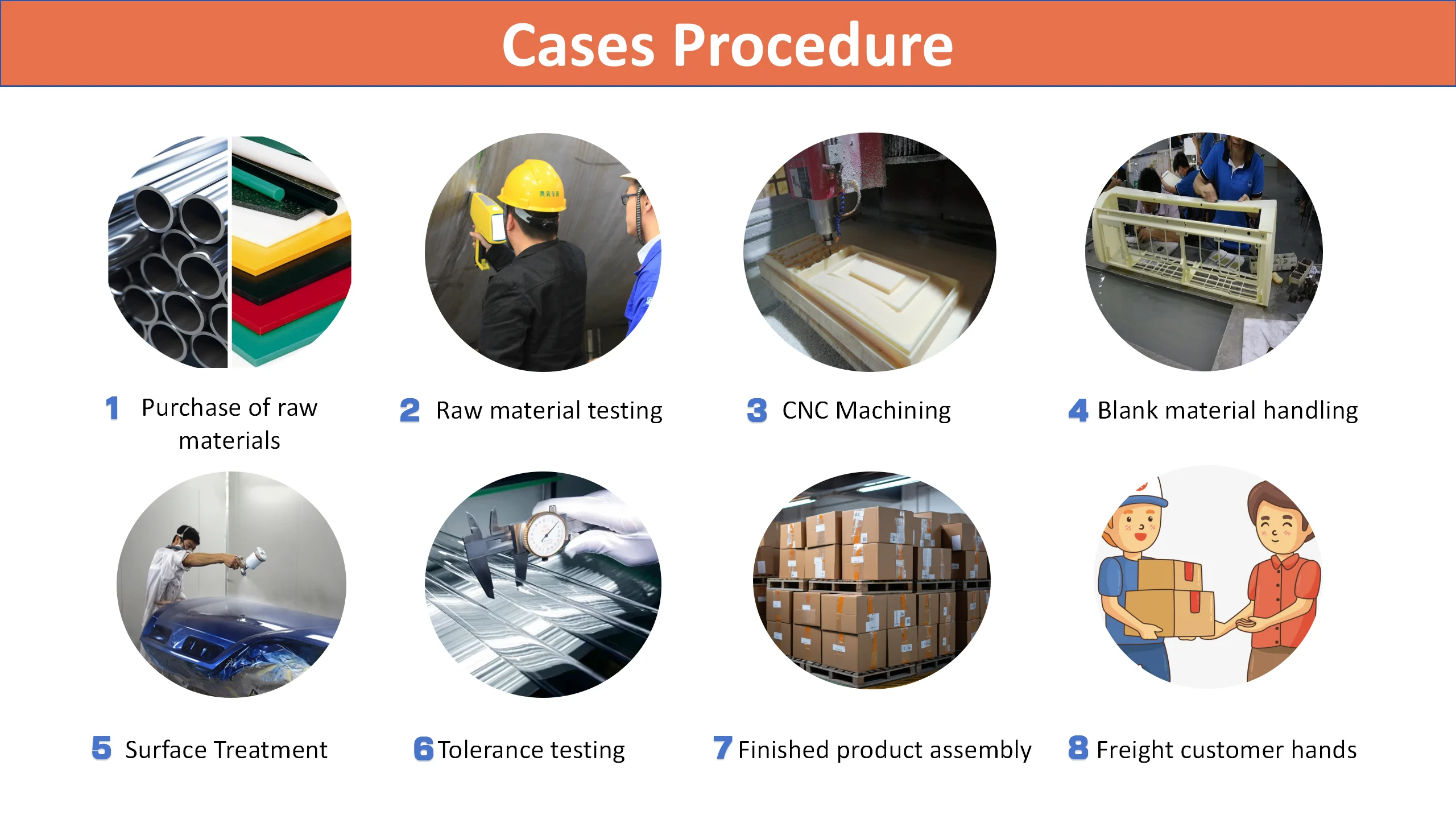

Cooperation Process

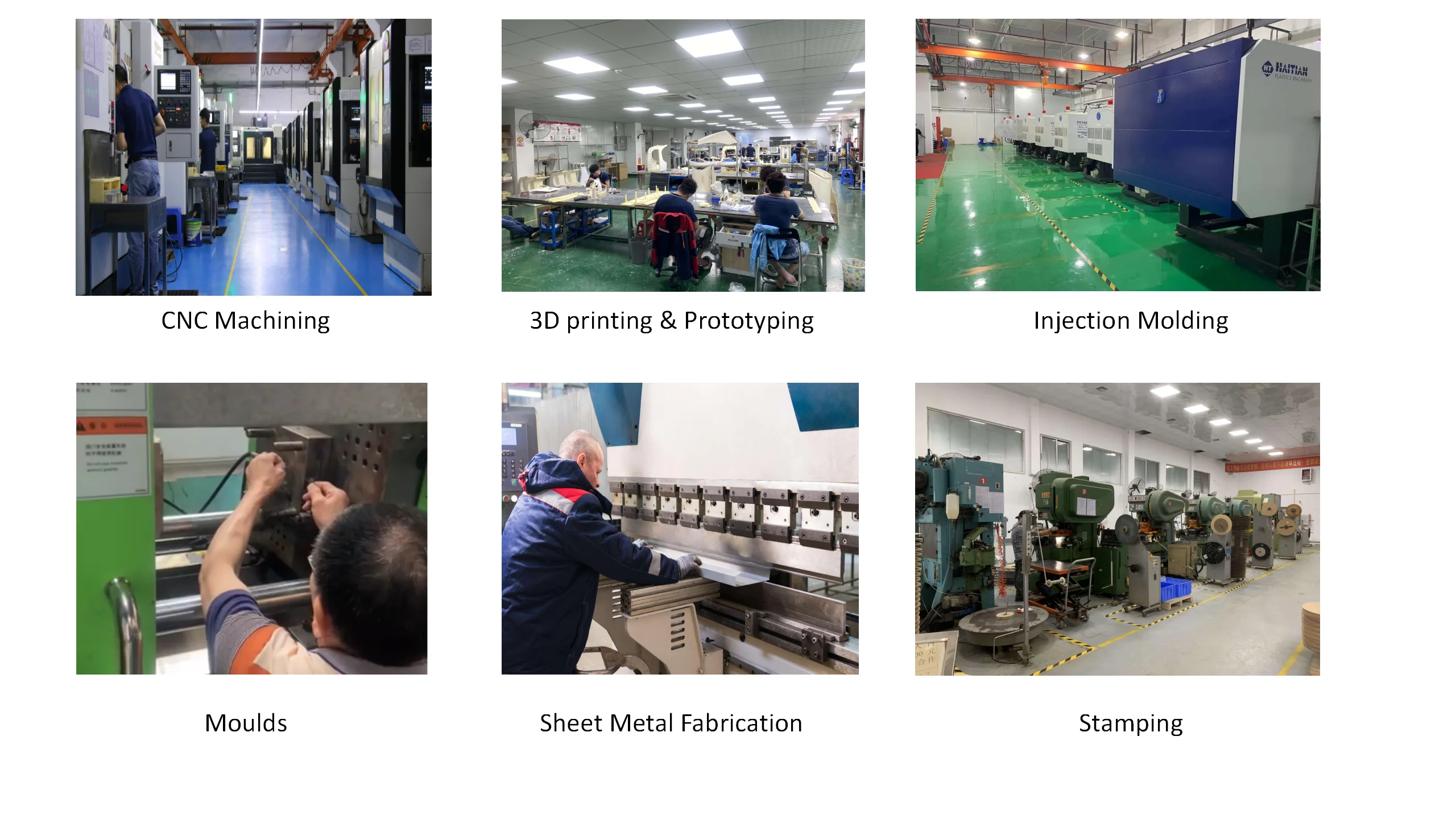

Machining ability

Overview: | 1.Tagged price not actual price, requires actual quote; 2.Buyers if you want to provide detailed drawings (CAD/DXF format, STP format or tolerance size) can contact our customer service, we can confirm the processing, please feel free to contact me; 3. Custom-ordered products do not support order cancellation |

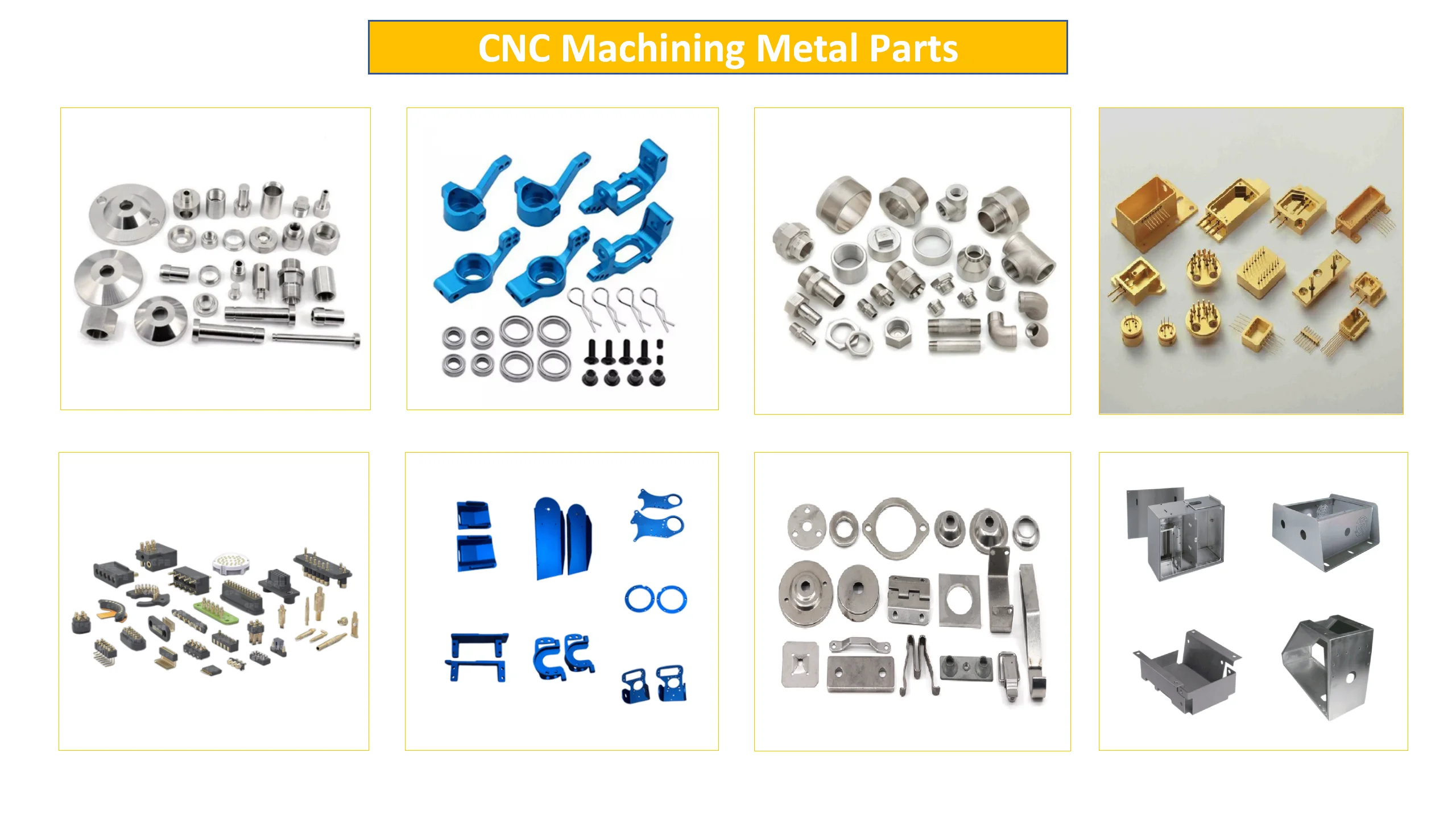

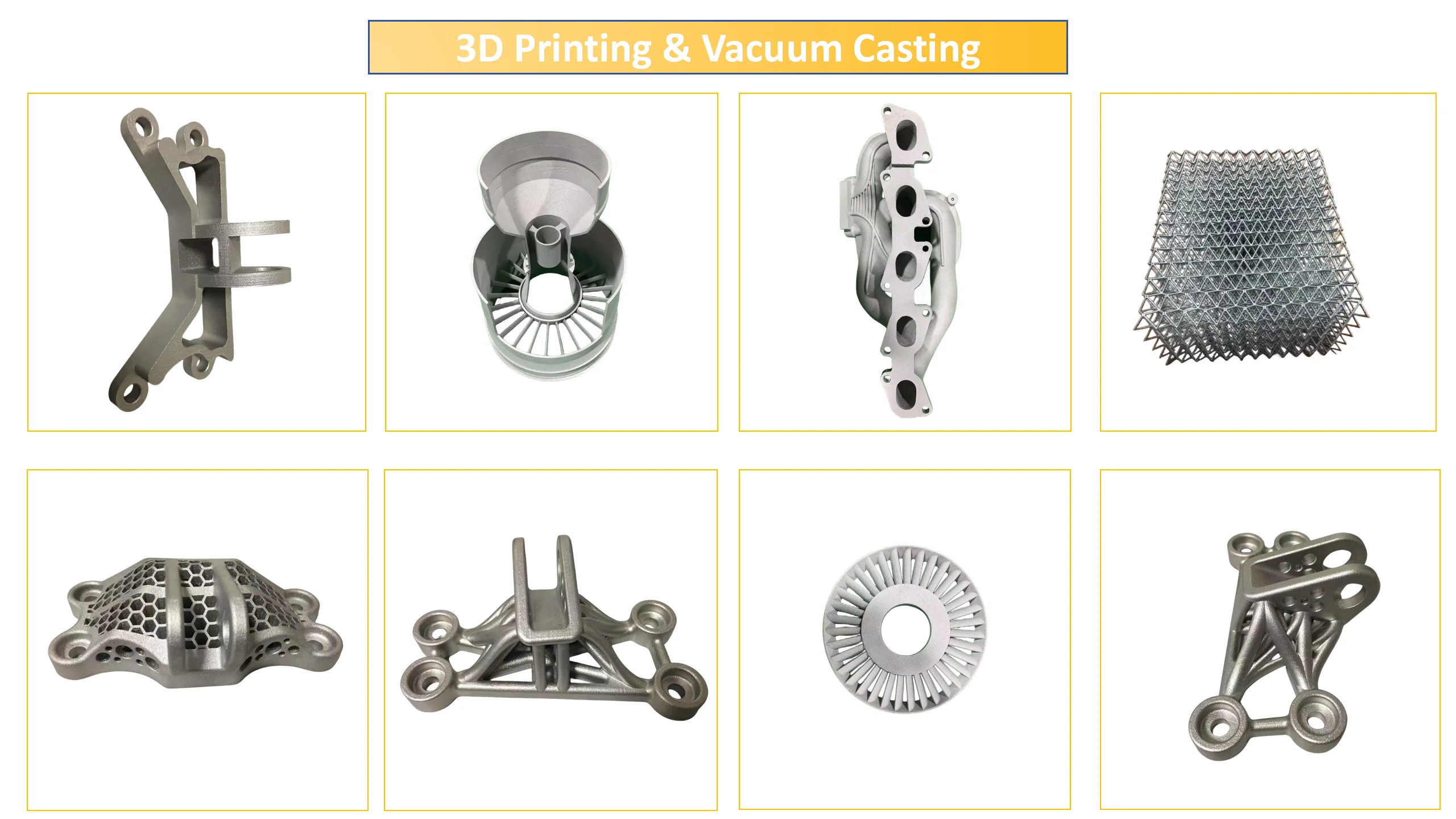

Description: | CNC Machining or Not:Cnc Machining |

Our Services: | Prototype Machining Service(NoMinimum) Non-standard Parts Customized Service(NoMinimum) One-stop CNC Machining Service(NoMinimum) Sheet Metal Fabrication Service(NoMinimum) |

QC control: | 100% inspection on critical dimensions |

Price: | CNC part factory price |

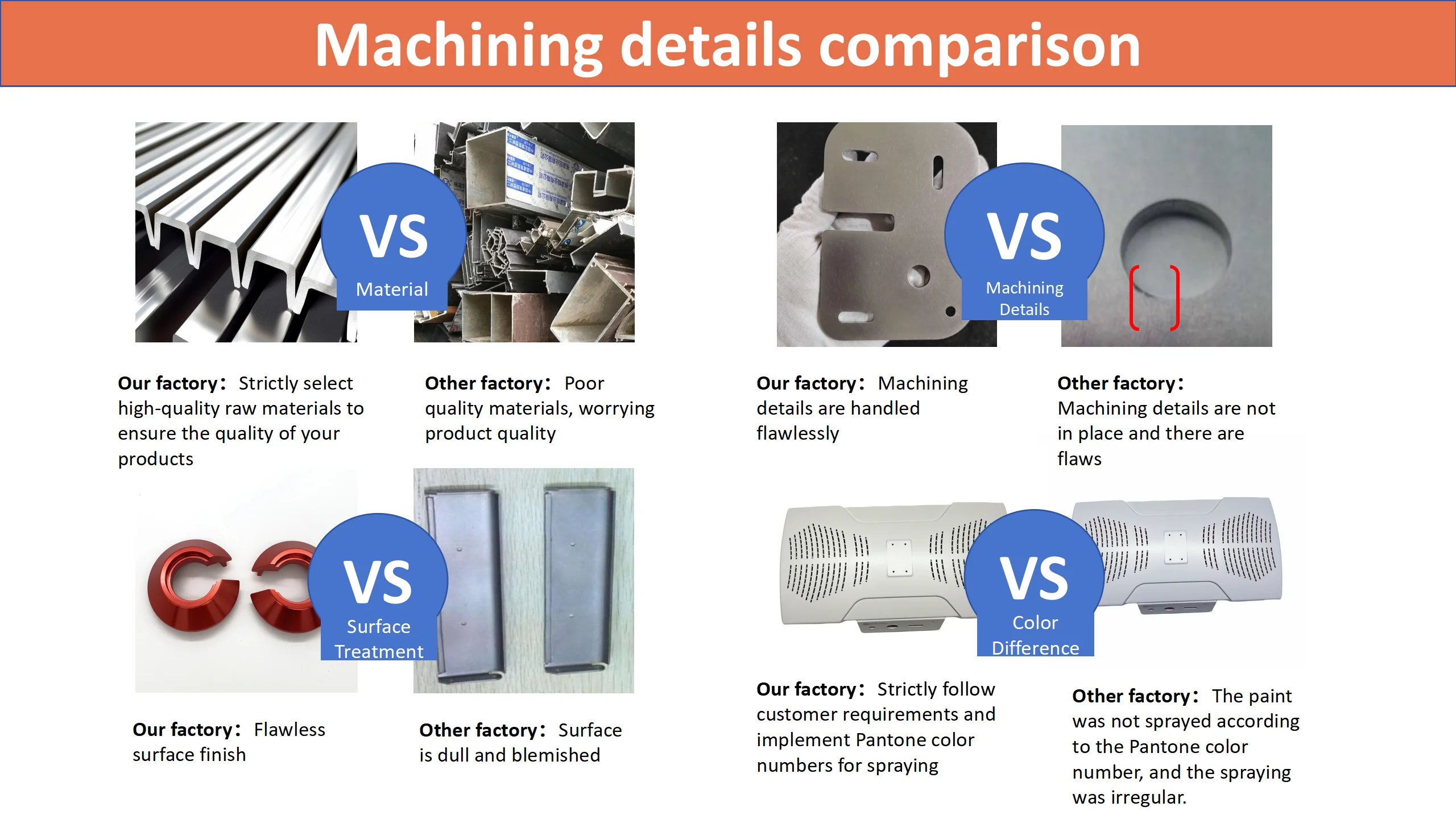

Why choose us: | Superior quality+on-time delivery+Prompt feedback+competitiv |

Processing: | CNC Milling,CNC Turning,Wire-cut EDM,Precision grinding,Lathe machining,Drilling. Bending,Stamping,Laser Cutting,Broaching. etc. |

Surface: | Anodizing,Sand blasting,Bead Blasting,Powder coating,PaintingAlodine/passivation, treatment zinc plating, silk printing,Laser etching,PolishingTeflon finish,Chrome plating, etc. |

Heat treatment: | Annealing,NormalizingNitriding,TemperingCarbonitriding,etc. |

Tolerance: | ±0.01mm |

Finish: | all kinds of finish available |

Testing equipment: | CMM. Tool microscore. Automatic heiaht gaugeManual height gauge,Digital Micrometer Marble platform,Roughness |

CNC Turning A Machining Process That Rotates a Workpiece While a Cutting Tool Removes Material from the Surface, Suitable for Cylindrical or Round-Shaped Parts Made of Various Materials Such as Metals, and Plastics, And Woods. Advantages: High Precision, Repeatability,And Efficiency in Mass Production. |

CNC Milling A Machining Process That Uses Rotary Cutters to Remove Material from a Workpiece, Suitable for Flat or Irregularly Shaped Parts Made of Various Materials Such as Metals, Plastics, And Woods. Advantages: Versatility in Creating Complex Shapes, High Precision, Repeatability, And Efficiency in Mass Production. |

Metal fabrication Processing 1. production machine: laser cutting machine,punching machine, bending machine 2. tolerance: +/-0.1mm | Stamping From welding and tapping processes to coatings and assembly, we offers an array of value-added services to accommodate our clients' metal stamping projects. |

Surface Finishing We provides real production-level surface finishing for rapid prototyping & production, such as painting, powder coat,anodized,and chromed finishes. |

Materials

CNC Machining & Sheet Metal Fabrication Materials | |||||

Aluminum | Stainless steel | Steel | Copper | Plastics | Titanium |

Aluminum 2024 | Stainless steel 303 | Steel Alloy 4130 | Brass C230 | ABS | Grade 2 |

Aluminum 5052 | Stainless steel 304 | Steel Alloy 4140 | Brass C360 | POM (Delrin/Acetal) | Grade 5 |

Aluminum 6061 | Stainless steel 316 | Steel Alloy 1018 | Copper 101 | PEEK | |

Aluminum 6063 | Stainless steel 416 | Steel Alloy 1215 | Copper 110 | Nylon (Polyamide) | |

Aluminum 6082 | Stainless steel 17-4PH | Steel Alloy 4140PH | PMMA (Acrylic) | ||

Aluminum 7050 | Stainless steel 15-5 | Steel Alloy 4340 | Polycarbonate (PC) | ||

FAQ

Q1:Where can I get product&price information? A1:Send us e-mail , we will contact you as we receive your mail. Q2: How soon can I get samples? A2: Depending on your specific project, it usually takes 10 to 20 days. Q3:How to enjoy the OEM services? A3:Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you. Q4:Can you make machining parts based on our samples A4:Yes, we can make measurement based on your samples to make drawings for machining parts making. Q5: Is it possible to know how are my products going on without visiting your company? A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress. |