Небольшая модель полуавтоматическая машина для производства кирпича с дешевой

- Категории: >>>

- Поставщик: Gongyi,Xinruida,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Overview

XRD4-35B Cement Brick Making Machine

The brick machine can produce all kinds of standard bricks, hollow bricks, large bricks and special-shaped bricks with good stability and fatigue resistance.Brick machine body all adopt high strength steel and special welding process manufacturing, hard to break open welding, extremely strong and durable.

Working Principle

Vibration platform adopts washboard cast steel technology -- to achieve the encrypted amplitude and average distribution of vibration force, which fully makes the vibration force gather on the vibration platform and increases the compactness and high strength of the block brick. At the same time, it reduces the destructiveness of the dispersed vibration force to the organism.

Product Parameter

No | Item | Data |

1 | Power | 4.8KW |

2 | Transmission Model | Machinery |

3 | Weight | 780kw |

4 | Raw Materials | Fly Ash,Cement |

5 | Molding Cycle | 35s |

6 | Pallet size | 850*550*30mm |

7 | Block specifications | Buliding Construction |

8 | Worker | 2-3 worker |

Raw Materials

1.Cement: Adding 10% ordinary Portland cement can improve the strength and water resistance of the brick, and it will not crack after soaking. Otherwise, cracks will occur in general bricks.

2. Clay: It must contain a certain amount of loose particles to facilitate the mixing of cement. The clay with low sand content can be mixed with sand in the soil. Clay with low sand content and hardness must be ground before mixing with sand.

3. Additives: Adding a small amount of additives (reinforcing agents), in addition to improving the hardening strength of bricks, can also reduce the amount of cement and reduce product costs.

4. Water: If the water consumption is proper, the strength of the brick will be high. The molding moisture is small, the strength of the brick is poor, the material has a large resistance in the mold, the pressure is on one side, and the bottom surface of the brick is not dense; the molding water is large, the bottom surface is wet, and it is easy to be damaged when it is ejected. When the moisture content of sand is 3-5%, the water consumption during molding is preferably 10%. If the raw fine sand is too much, it will be reduced to 8%.

2. Clay: It must contain a certain amount of loose particles to facilitate the mixing of cement. The clay with low sand content can be mixed with sand in the soil. Clay with low sand content and hardness must be ground before mixing with sand.

3. Additives: Adding a small amount of additives (reinforcing agents), in addition to improving the hardening strength of bricks, can also reduce the amount of cement and reduce product costs.

4. Water: If the water consumption is proper, the strength of the brick will be high. The molding moisture is small, the strength of the brick is poor, the material has a large resistance in the mold, the pressure is on one side, and the bottom surface of the brick is not dense; the molding water is large, the bottom surface is wet, and it is easy to be damaged when it is ejected. When the moisture content of sand is 3-5%, the water consumption during molding is preferably 10%. If the raw fine sand is too much, it will be reduced to 8%.

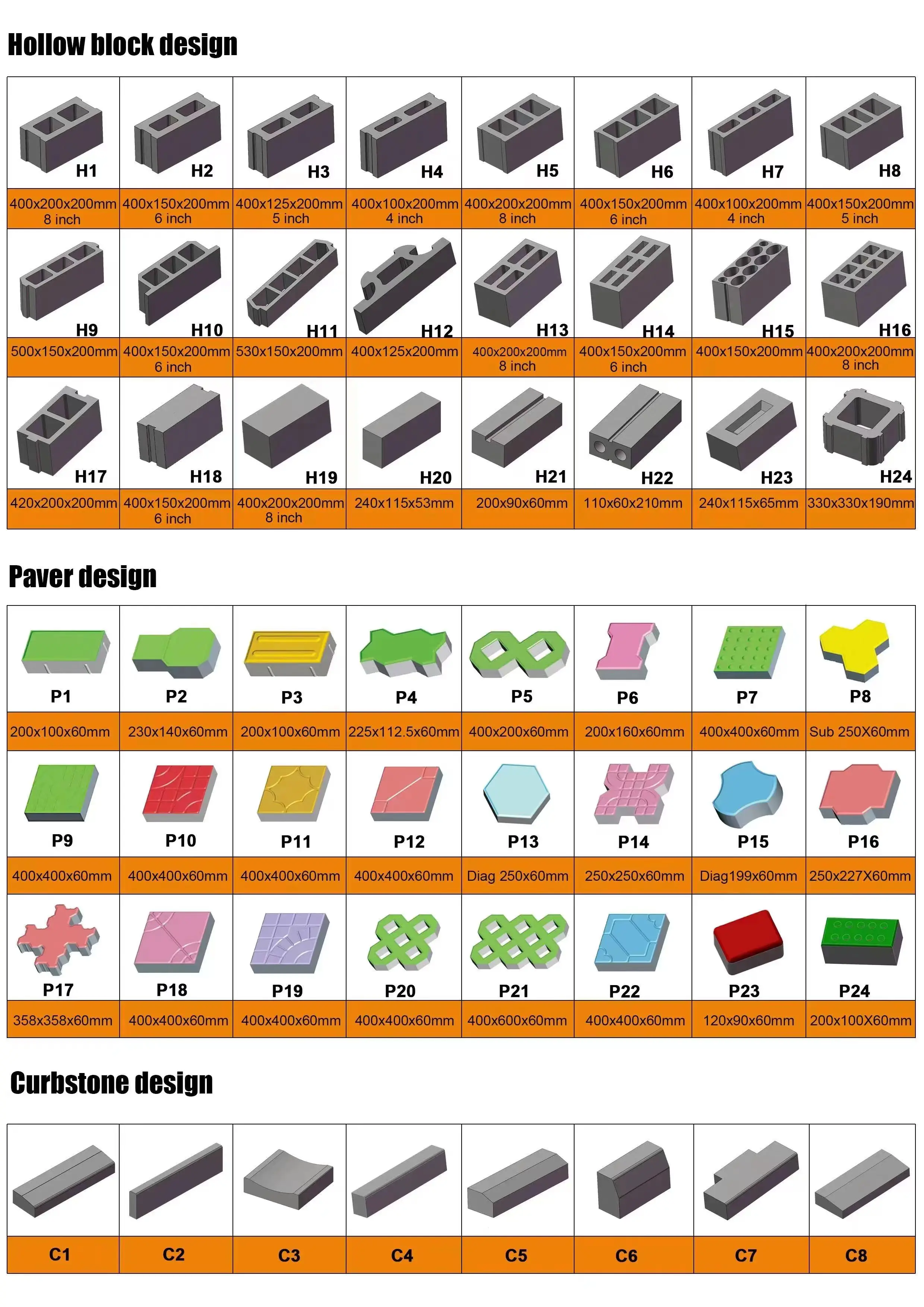

Brick Types

Similar Product

Company Profile

Xinruida Machinery Equipment Co., Ltd. is located in Gongyi City, Henan Province, is a company with more than 20 years of production experience,and is a equipment manufacturer with complete testing equipment and a strong technical force. There are many kinds of mechanical products, good quality, novel style, and reasonable prices, which are widely used in mining and other related industries. Our products keep up with the evolving industry direction, to meet the diversified needs of customers, widely recognized and trusted. Products sell well in North America, South America, Africa, Asia, and other countries and regions, the number of new and old customers steadily increases, customer trust is our biggest driving force, we insist on doing better products!

FAQ

Q1: How do I know which model is suitable for my bricks?

A: Please inform us your brick sample pictures or brick drawings , we will suggest you our suitable types for your reference.

Q2:What is your package for shipment?

A: Usually safety export package(steel box) for LCL,Nude package for full container. or as customer's requirements.

Q3:How long about the delivery time?

A: The delivery time shall be determined according to the type,Within 15-25 days after received deposit usually.

Q4: What is the useful life of your machine?

A:usually 8-10 years

Q5:How long is your warranty terms?

A: Our Warranty terms is 1 years guarantee.

Contact Us