Электрическая машина для производства блоков высокая производительность городского сада мощение известкового кирпича

- Категории: >>>

- Поставщик: Gongyi,Chenghui,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

PRODUCT OVERVIEW

4-28 Automatic Block Making Machine Produce Various Brick Types

4-28 is a fully automatic hydraulic block making machine. with many advantages like High output, saving manpower,easy in operating,and durable in use. This fully automatic brick production line is small in size, covers a small area, and saves

manpower, so the investment is small and the return is quick.

manpower, so the investment is small and the return is quick.

Advantage

1. Save manpower and material resources, improve production efficiency, environmental protection and energy saving.

2. The bricks produced have high strength and good density, and can be stacked and dried at any time.

3. The mold can be replaced at will, truly

realizing one machine with multiple uses.

realizing one machine with multiple uses.

4. Consumable parts are not only convenient for maintenance, but also users can save

mold costs.

mold costs.

4-28 is a automatic hydraulic brick making machinery which is specialized in construction building block such as hollow block, solid block, paver block , porous brick , road kerb , grassing brick , ring tree brick and other concrete products .The material can be fly ash , cinder , coal gabgue and other industrial residue . Add the color material feeding machine (color system ) can produce colored products .

The pan mixer breaks up and mixes the tiny particles separated from each other in the mixture of different components. It is mainly composed of a mixing barrel, a mixing blade, a motor, a reducer, etc. The contact area between the mixture and the mixer is minimized to reduce the residence time of the mixture on the mixer.

Belt conveyors can feed continuously, have large conveying capacity, simple structure, and easy maintenance. They can also perform horizontal, inclined, and vertical transportation to meet different operational requirements.

TECHNICAL PARAMETER

Item | Data |

Model | 4-28 |

Type | Automatic |

Power | 12kw |

Molding cycle | 28(s) |

Mold Size | 800*400*200mm |

Dimension | 3200*2100*2350mm |

Weight | 1800kg |

Item | Data |

Model | JW750 |

Power | 7.5kw |

Diameter | 1.3m |

Packaging Dimensions | 1300*1300*1200mm |

Weight | 400kg |

Item | Data |

Model | CH-600 |

Power | 1.5kw |

length | 6m |

Machine Dimension | 6300*350*650mm |

Packaging Dimensions | 3200*700*650mm |

DETAILS IMAGES

National Standard Steel Q235B

Hardness and wear-resistant ability is 1.3 times better than common steel and carbon dioxide gas protection welding.

High Quality Motor

Famous brand quality, ensure the machine to run steadily and safely, long service life.

High Quality Block Molds

The mould are all treated by High temperature carburizing.The service life are 3 times longer than normal one.

Control Cabinet

The control cabinet monitors, protects and controls the electrical system to ensure the normal operation of the electrical system.

PRODUCTION PROCESS

1. Design And Draw The Brick Drawings

2. Cutting Steel Plate

3.Finished Mold

4. Environmentally Friendly Paint Spray

5. Assembling Machines

6. Testing Machine

APPLICATION FIELD

Various raw materials applicable: Fly ash, Steel slag, river sand, stone powder, slag, Coal Gangue,

.constructioin waste, stone etc.

Concrete cement bricks can produce different types of bricks.

It can also be customized according to demand.

Free giving a conventional brick mold, and brick molds can also be customized according to demand.

Free drawings are provided to customers who need customized brick types

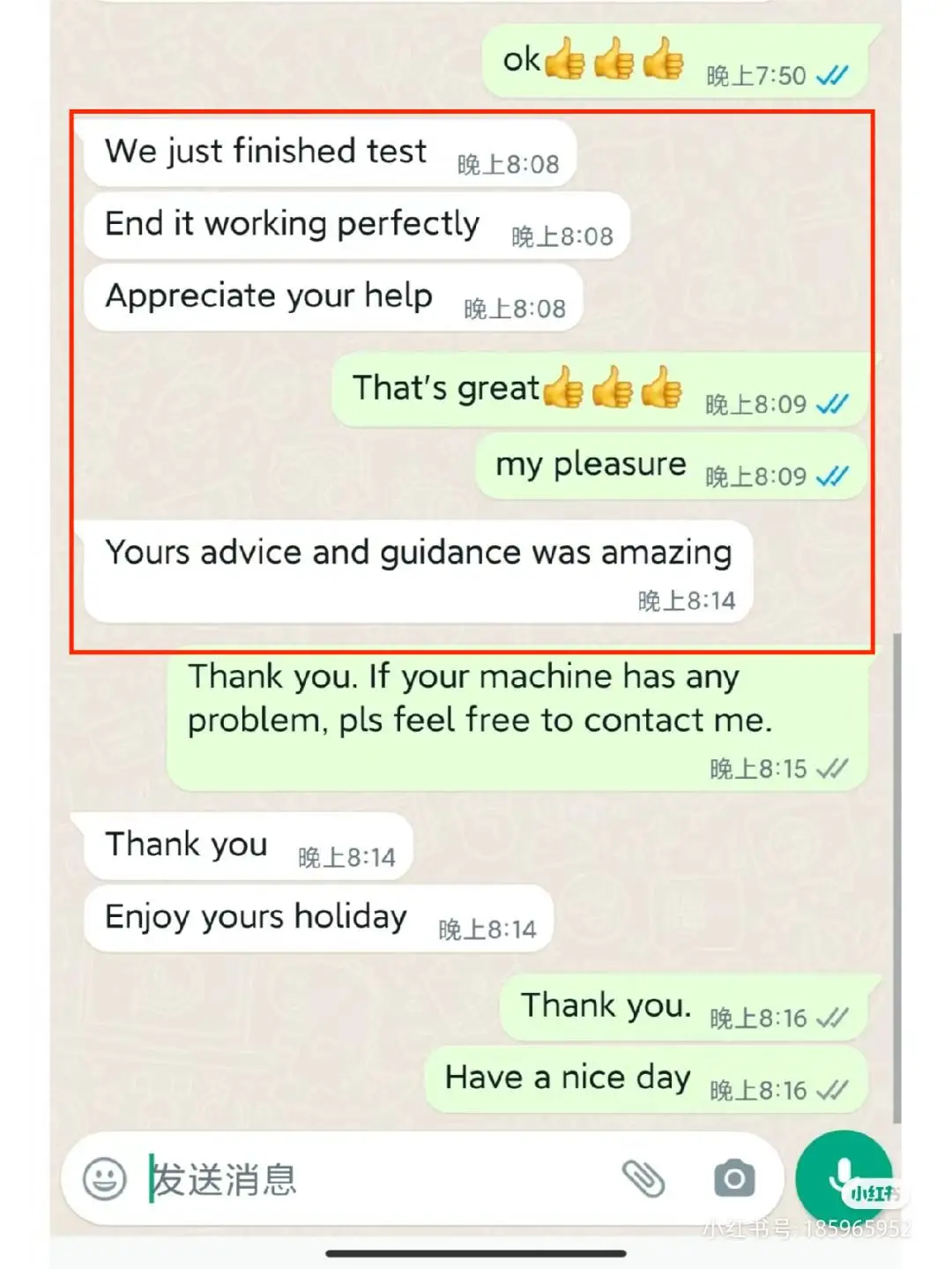

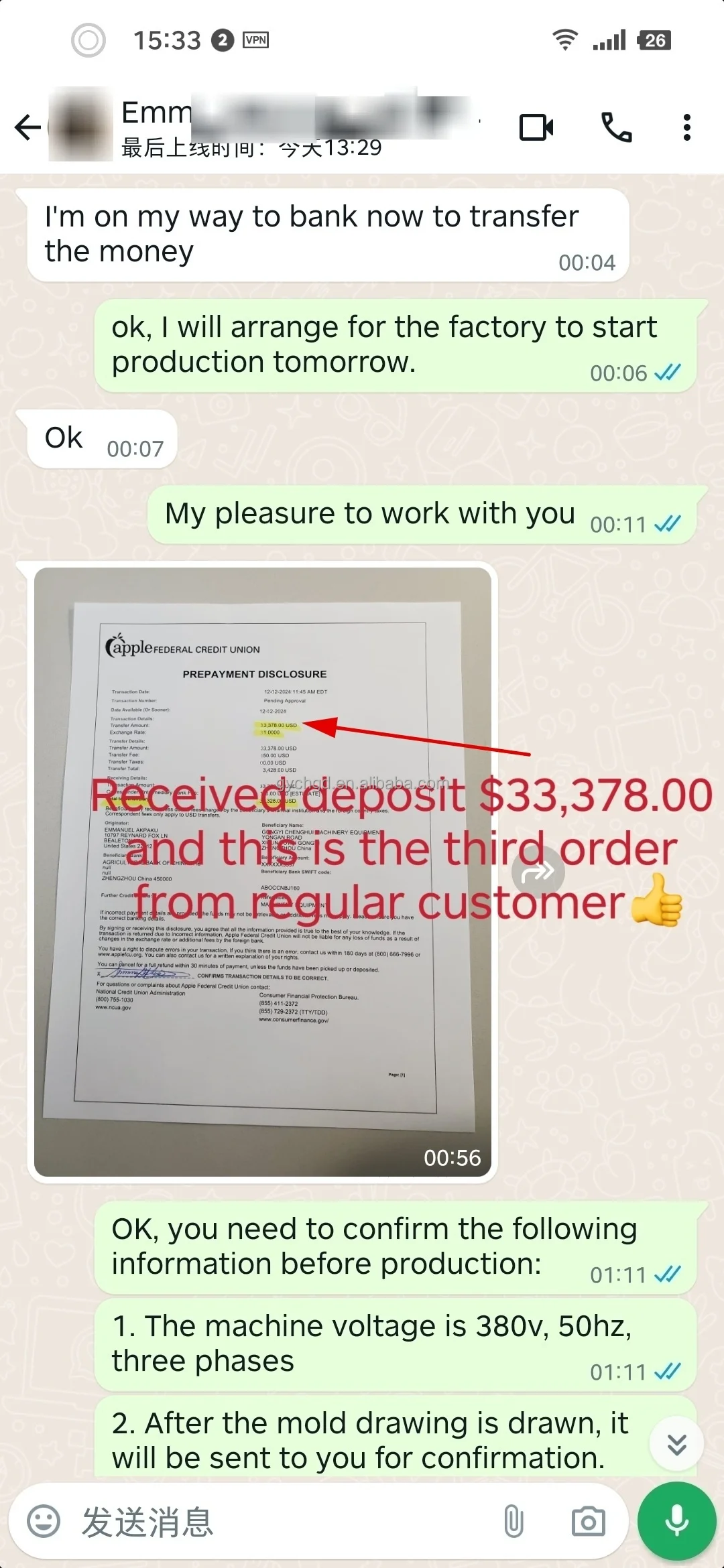

SUCCESSFUL PROJECT

Project in Zimbabwe

Project in Ghana

Project in Jamaica

Project in Nigeria

Project in Ghana

WHY CHOOSE US

Certain Suppliers

ChengHui Machinery

Reason 1: Mold Manufacturing Process

The mold of the brick making machine is not precise enough, which affects the brick forming effect, resulting in the collapse of the shaped bricks.

Reason 2: Vibration Intensity

Inferior vibration motors cannot reach the calibrated power, and insufficient vibration intensity will cause the raw materials to be unable to be fully compacted and the interior of the bricks to be loose.

Reason 2: Vibration Intensity

Inferior vibration motors cannot reach the calibrated power, and insufficient vibration intensity will cause the raw materials to be unable to be fully compacted and the interior of the bricks to be loose.

ChengHui Machinery’s mold plates use laser cutting technology with an error as low as 1 mm.

ChengHui Machinery uses high-quality motors to ensure that the vibration intensity reaches the standard.

Other Reasons:

Too much or too little moisture in the raw materials, uneven particle size of the raw materials or excessive impurities, improper raw material ratio, insufficient molding cycle time, etc. will all affect the brick molding effect.

Different solutions can be adopted for different problems, such as adjusting the moisture content of raw materials, increasing vibration intensity, repairing molds, optimizing the raw material ratio, etc. By analyzing and optimizing these problems, the production efficiency, brick quality and service life of the brick machine can be improved. Contact us to get more details.

FAQ

Q1:What is the warranty for this machine?

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.

A1:3 years excluding the easy wear parts.Spare parts is recommended to keep at least one year in case of emergency

Q2: What kind of material is this machine made of ?

A2: Stainless steel and carbon steel.

A2: Stainless steel and carbon steel.

Q3: When can I get the price?

A3: Within 24 hours. If urgent, please directly call us.

Q4: Can the price be much lower?

A4: Our MOQ is the very reasonable price for 1 set, but with big order, we can apply to our Manager to provide a proper discount.

Q5: Do you offer oversea installation?

A5: We'll send professional installation engineer to help you install the equipment, as well as train your workers freely.