Машина для производства бетонных стеновых

- Категории: >>>

- Поставщик: Guangxi,Hongfa,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

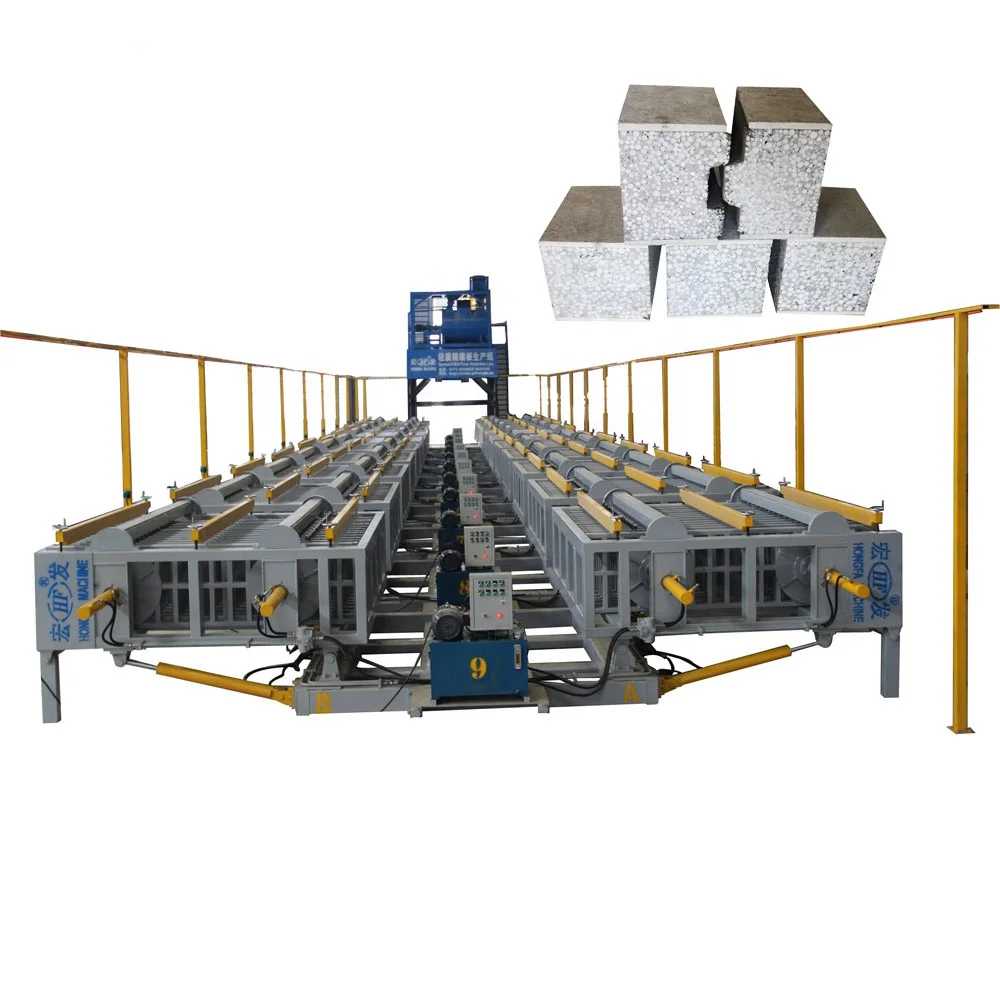

Precast Concrete Wall Panel Machine Sandwich Lightweight EPS Cement Wall Panel Mould Car/Board Making Machine for House Material

HF concrete precast houses prefab home precast concrete sandwich plate machine to make PET foam core wall block board panels

Applications of Precast Eps Sandwich Wall Panels/Lightweight Cement Board

The Wall panel is widely used for partition board in non-bearing wall,exterior wall in steel structure,roof and floor.It is popular for new construction or renovation and expansion building,such as house construction,fire wall,fences,footings,retaining walls,bungalows high-rise buildings,basements,walk-in fridges,hotels,schools,shopping malls,villas and etc.

The use of new wall materials can significantly reduce the weight of the building, creating conditions for the promotion of light building structures, to promote the modernization of building construction technology, greatly speed up the speed of building.

It can be seen that the new wall materials have created good economic, social and environmental benefits, and have received strong support from national policies. Therefore, the new wall materials have been recognized and favored by the society.

Hongfa group since 1990, We mainly provide kinds of Lightweight EPS Wall Panels Making Machine for Choice.

A leader developer& Manufacturer of Construction Material Machinery.

EPS thermal insulation wall board styrofoam sandwich partition wall panel machinery for concrete foaming wall panel machine

1.Hongfa automatic vertical concrete EPS sandwich wall panel making machine. HFP530A (Medium Cost,Big Capacity,Less Labours)

Hongfa is the first one to design and produce this kind of machine

1. Install fiber cement board and aluminium molds quickly. 2-3 labors can finish 1 set of molding car(30 pcs 100mm thickness panel)within 15mins.

2. 8 hydraulic cylinder guarantee dividers keep tightly when curing. Cement hydration reaction(curing) will expand inside of the machine, so machine's design is important for panels flat surface.

3. Demolding is fast and it will not affect molds installation efficiency.

4. Verified efficiency: 7 labors can get 900sqm per 8 hours.(130sqm/labor/shift)

5. Patent protected product

6. Labor-saving and Advanced Technology

7. Double side opening and higher capacity

8. ISO9001-2015

9.Adopts touch screen control, automatic filling, electronic weighing, temperature control, material level control to realize automatic production.

10. Easy to maintainence, Easy to clean.

3.Hongfa horizontal EPS concrete lightweight wall panel making machine.HFP512A(Low Cost,Small Capacity,Less Labours)

1.High strength

2.Fast pouring

3.The finished wall panel strong and beautiful

4.Easy to use/operating

5.Low labor intensity

Precast Concrete Eps Wall Panel Machine Adobe Lightroom Board Making Machines for prefabricated-building production line

For the production moulds use in our EPS sandwich wall panel production line and for our customer, it can keep using for 10 years without any deformation, that is because we take use China famous brand raw material and the most small thickness can reach to 4MM and also our special technology to ensure the high quality and long service life.

Hongfa one production line of wall panel machine can produce kinds of wall panels

Tilting Table Foaming Concrete Slab Precast Concrete Lightweight Eps Sandwich Wall Panel Making Machine For Prefabricated House

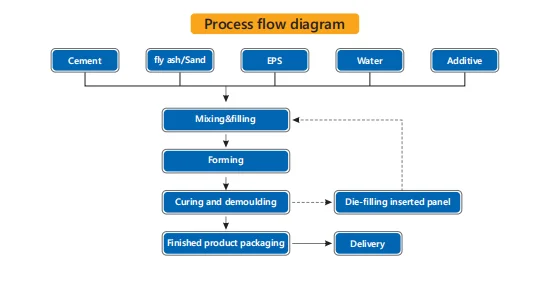

1.Outsite(with side board or without)

*Calcium silicate board,Cement fiberboard,MGO Board.

*Also can be without the side board and adjustable.

2.Inside(core material)

*EPS,Sand,Cement,Additives or Fly Ash(Coal Boiler), Water, Perlite, etc.

Advantages of the widely used eps concrete wall panel

Lightweight precast concrete insulation wall panel machines eps cement sandwich wall panels drywall production line

The new wall material has the characteristics of light weight, heat insulation, sound insulation, heat preservation, no formaldehyde, no benzene, and no pollution. Some materials even achieve the function of fire protection.

The development of new wall materials has a huge impact on building technology and may change the form or structure of buildings. New wall materials include new raw materials and products, as well as new products of original materials.

Lightweight wall panel machine precast concrete wall panel machine with Good Price

For the EPS Sandwich Wall Panel Production Line/Precast Concrete Wall Panel Plant/Lightweight Wall Panel Machine Line,we have lots of sucessful case all over the world, such as India,Philippines,Uzbekistan,Dubai,Qatar,Kazakhstan,and etc. and here below some cases for reference.

Package for the Wall Panel Machine: Naked packing or Stretch film packing or according to Customers' Requirements

After sales service

2.We will provide you with a set of spare parts for free!

3.Engineers available to service machinery overseas

4.When we go to the local exhibition, we also visit the customers to check the operation of the machines.

Company Instruction

Brand and Quality

Hongfa Machinery's Honor

One of Top Ten Influential Brands in China Brick &Tile Industry

China National Enterprise Abiding By contract & Keeping Good Faith

Quality and Credibility of the Dual-protection Demonstration Unit

High and New Technology Enterprise

Famous Trademark of China

Star Enterprise with China Patent

AAA Grade Credit Enterprise

Consumer Satisfaction Unit

One of Top 100 building Material Industry Brands of China

One of Top Ten Good Faith Units

Advanced Exporter in Guangxi Province

Advance Quality Management Unit

For any question, please feel free to contact with Ms.Fiona for reply

Sales manager: Fiona Yao

Tel:86-18775047415(what sapp/ We Chat)

Guangxi Hongfa Heavy Machinery Co.,Ltd

Wesite:www.gxhongfa.cn