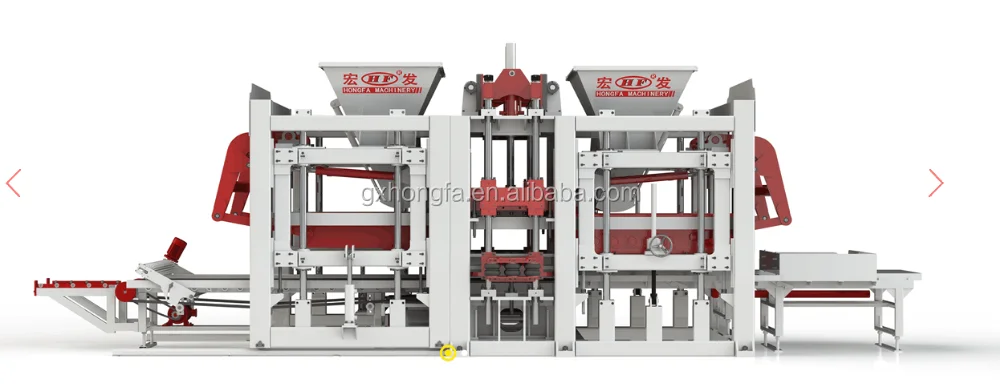

HONGFA Автоматическая установка для производства блоков машина опилок каменных пластиковых цена оборудование

- Категории: >>>

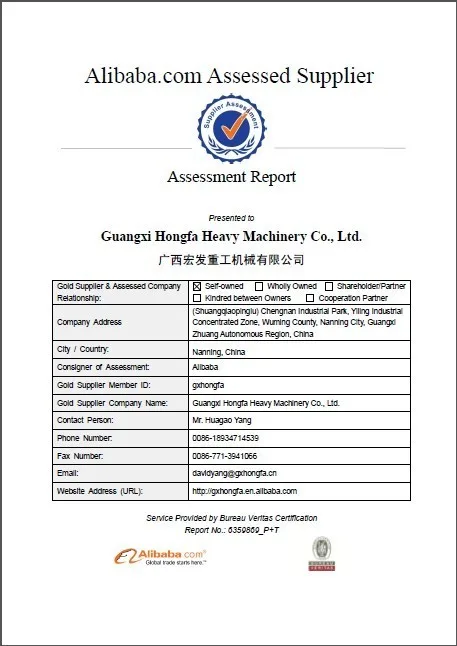

- Поставщик: Guangxi,Hongfa,Heavy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

automatic block making plant block machine brick machine shape mold form build make press machine brick making machinery brick making machine manufacturing brick machine blocks brick making machine brick machine price brick making machinery making money at home online machines for small businesses block machine block making machine brick making machinery

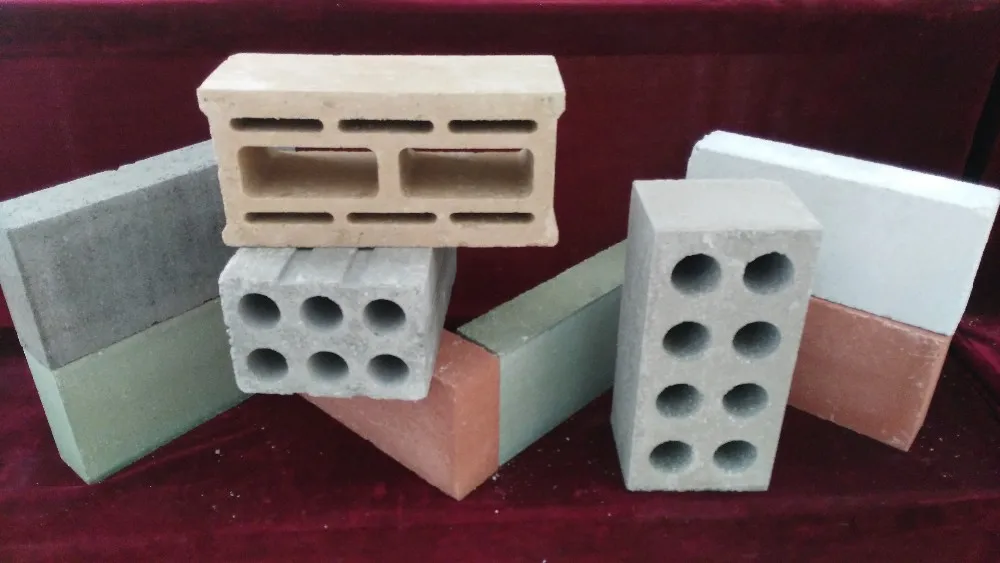

1.HFB5250A brick making machinery can produce different size and different type of blocks by changing moulds.Such as concrete hollow block,paver brick,kerbstone block and so on.

2.Our brick making machinery moulds are made of manganese steel and adopt carburization and heat treatment technology,which can enhance resistance of the mold, prolong the cycle lifespan and keep precise size of the blocks .

3.Our brick making machinery select Siemens PLC control system, electronic components and Motor , which ensure high efficient working status and superior quality .

4.Simple operation and low (frequency changeable motors)frequency in feeding concrete and high frequency vibration when pressing which can save 25% energy compared to the same industry and protect the motors

5. The comtrol system has the self-diagnosis function, which can find out the system problem quickly and fix it.

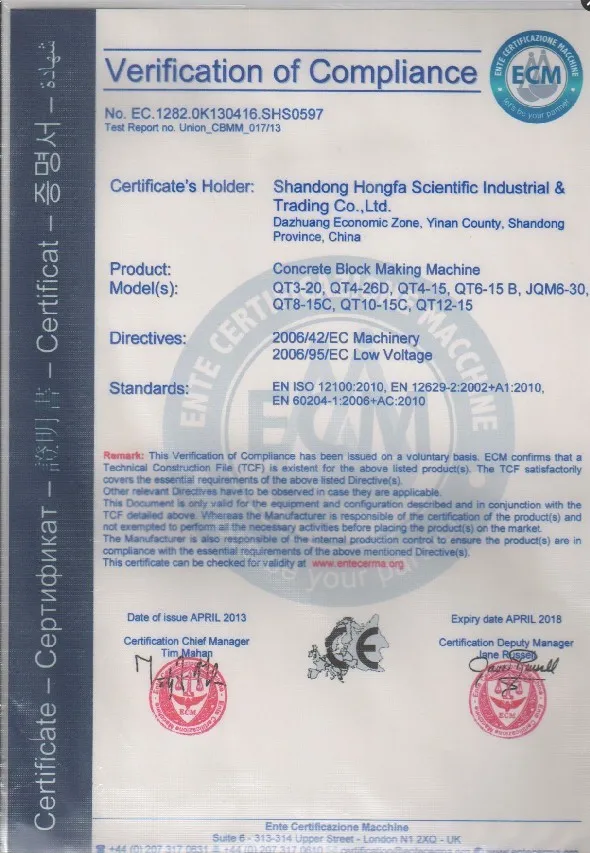

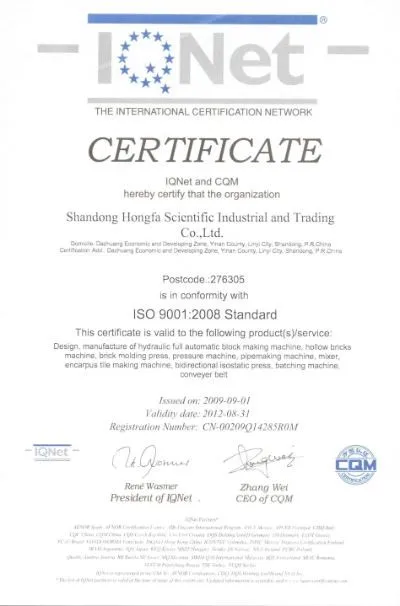

6. ISO 9001 and CE certifications.

Overall Dimension :\t8200X2600X3020 (mm)

Rated Pressure :\t21 MPa

Main Vibration Form :\tPlatform vibration

Cycle Time :\t15~20 seconds

Vibrating Frequency :\t2800-4500 rolls / minute

Motors Power :\t66 KW

Pallet Size :\t1420×900 (mm)

The frame is 200*200mm with 10mm thickness

Using Siemens touch screen, Siemens control system and Siemens motors

Using Taiwan Calyca Hydraulic system and Double proportion valves

1. 4 polts guiding to elevate the top mold and get more stable moving

2. Adding 2 pcs of guiding shafts and one adjusting wheel on each side ,so it can be very easy and faster to adjust the materails feeder height.

3 pcs of airbag in each side, it can perfectly absorb the vibration and protect the machine.

The materials feeder box runned by bearing and inside it use Copper based powder metallurgy set , it can run more than 10 years and no need to change.

1. Change to swing type feeder, so even it jammed by big stone, the motors won't break down or burn.

2. Adding Wear resistant sleeve with heat treatment, so that it can run longer.

3. Adding stainless steel on the placing boom, so that the materials can be feeded into the mould faster and even.

2. Drawbar is solid and one pcs only, so it will never broken.

3. From two motors changed to one bigger motor, whenever one force will be more focus and synchronize than two.

4. Using PH400 wear-resisting alloy steel in bottom of material feeder,the yield strength is up to 1200Mpa.

1. Adding 5 more Over-pressure-proof supports on the low-mould support flatform and the supporting bar with heat treatment (more durable and make sure no pallet broken when demoulding )

2.The steel board under the vibration platform used 50mm thickness manganese steel,it will make sure very good performance during operation and longer longlife span.

1. There are vibrator and vibration case and extra 2 pcs of Cardan shaft and one Synchronous box, which can increase the vibration synchronism

2. Using dry vibration case, so running faster and no oil leaking .

automatic block making plant block machine brick machine shape mold form build make press machine brick making machinery brick making machine manufacturing brick machine blocks brick making machine brick machine price brick making machinery making money at home online machines for small businesses block machine block making machine brick making machinery

We are a construction and building material equipments manufacturer mainly produces all kinds of AAC block production line, concrete mixing plant, mixer, concrete block making machine, concrete tile making machine, concrete pipe making machine etc, with more than 27 years experience and being the biggest manufacturer at present. All the products are conformity with the standard of the state and gets the ISO9001 certificate and also honored as " One of The Top Ten Famous Brands of Brick and Tile Field in China"and other honors. Hope to cooperate with you .

HONGFA workshop

Our honors

2.China National Enterprise Abiding By Contract & Keeping Good Faith

3.Quality and Credibility of the Dual-protection Demonstration Unit

4.High and New Technology Enterprise

5.Famous Trademark of China

6.Star Enterprise with China Patent

7.AAA Grade Credit Enterprise

8.Consumer Satisfaction Unit

9.One of Top 100 building Material Industry Brands of China

10.One of Top Ten Good Faith Units

11.Advanced Exporter in Guangxi Province

12.Advance Quality Management Unit

We are a Direct factory, not agent or trading company, and the quality and after-sale services is guaranteed.

Welcome to visit our factory at any time.

We are an ISO9001 and CE certified factory,

Our quality and on time delivery is your guarantee to a successful project.

Our service:

FAQ for Production of brick making machinery:

Q: Are you trading company or manufacturer ?

A: We are Direct factory, not agent or trading company, and the quality and after-sale services is guaranteed. Welcome to visit our factory at any time.

Q: How long is your delivery time?

A: 20~30 days after receipt of deposit and molds confirmation from Buyer.

Q: What is the product guarantee period ?

A: One year after installation finished at buyer's factory.

Q: What about the payment?

A: 30% as down deposit by T/T ,70% as the balance paid by T/T before loading(L/C is also acceptable).

Q:Raw material of concrete brick making machine need?

A:Stone powder, pigment, crushed stone, cement.

Q:How many workers need in whole production line?

A: 3-5 workers will be ok in the brick making machine production line.

Q: How can you guarantee the production quality?

A: All our product are ISO9001 and CE certified. We have more than 30 years experience on producing the machines and will be inspected by QC team for each shipment. We have strictly quality control system in our production process. We do inspection for each batch of finished product before packing. Third party inspection is acceptable.

Q: How about the commissioning of the machine and training to workers?

A: After finish the installation of the production line, our engineer will do the testing and commissioning, and make the most suitable ratio of the materials to make the bricks, and train the workers how to operate and maintain the machines.