Мобильный Harbour портативный стреловой кран плавучий док козловой однобалочный мостовой Портальный

- Категории: >>>

- Поставщик: Henan,Huada,Heavy,Industry,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Mobile Harbour Portable Jib Crane Floating Dock Gantry Crane

A single-jib portal crane is a type of crane that features a single horizontal beam or jib mounted on a portal frame structure, and is commonly used in industrial settings, shipping ports, warehouses, and construction sites for a variety of lifting and material handling tasks.

Single Jib Portal Crane Drawing:

Single Jib Portal Crane Technical Parameters:

| Elevating Capacity | Lifting Capacity | Main Hook | Aux. Hook | |

| 120t | 40t | 20t | ||

| Radius | 24~33m | 24~60m | 28~65m | |

| Lifting Height | 60m | 60m | ||

| Working Radius | Max. | 60m | 65m | |

| Min. | 24m | 28m | ||

| Speed | Lifting Speed | 6(12, <48)m/min | 15(<8, 30)m/min | |

| Luffing Speed | ~10m/min | |||

| Slewing Speed | 0.24r/min | |||

| Traveling Speed | 30m/min | |||

| Power Source | 3-Phase A.C. 50Hz 380V | |||

| Track Gauge/Wheel Base | 13/16 | |||

Single Jib Portal Crane Features:

1. Jib or Boom: extend horizontally from the main structure, provide a pivot point for lifting and moving loads vertically and horizontally.

2. Portal Frame Structure: two vertical columns or towers connected by a horizontal beam, provide stability and allow the crane to span a specific area or track.

3. Mobility: mounted on wheels or rails, providing mobility along a fixed path or track.

4. Hoist Mechanism: attached to the jib or trolley, enabling the crane to lift and lower loads vertically such as electric wire rope hoists or chain hoists.

5. Control System: equipped with a control system to ensure precise and safe operation.l

6. Versatility: equipped with different types of lifting attachments or spreaders to adapt to specific load requirements.

Huada Heavy Industry specializes in providing the world with a range of customized construction solutions and equipment covering straddle carrier, rubber tyred gantry crane, girder trailer, gantry crane, portal crane, travel lift, launching gantry, beam launcher and overhead crane. Its product range is widely used in LRT, MRT, Metro, expressway, viaducts, interchanges, cable-stayed bridge construction, etc.

1. Customized Design

More than 50 R&D personnels with advance science and technology

18 years experience in lifting equipment design

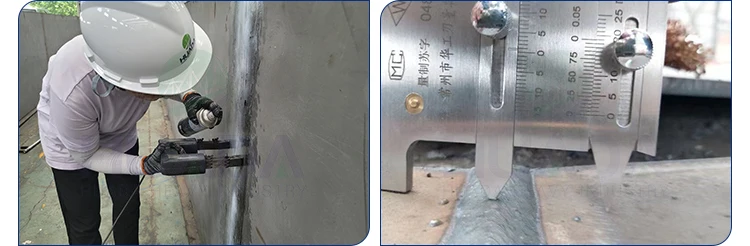

2. Strict Quality Control in Production: raw material, blanking, weld, inspection, painting

a. Welding Test Inspection

UT (ultrasonic test) for Butt Weld joints only + Spot check of MT (magnetic particle testing)

b. Painting Inspection

Epoxy zinc rich primer & polyurethane top-coat. The total thickness of the film ≥120μm

Strictly checking painting adhesion, paint film thickness and paint appearance color

3. Factory Installation & Commissioning before Delivery

4. Packing & Delivery

5. Experienced After-Sales Service in Time

a. Crane Operation and Maintenance Guidance

Free remote on-line inspection and maintenance guidance perpetually

Provide user operation maintenance manual with English Version

b. Quality Warranty(12months from the B/L date)

Within the warranty period: free parts provided (excludes man-made damage)

After the warranty period: recommend matching parts, you can decide to purchase spare parts from Huada Heavy Industry or other manufacturers