Промышленный водородный генератор водородная заправочная станция поток 10 нм 3/ч рабочее давление 1 6 МПа оборудование для генерации

- Категории: >>>

- Поставщик: Sichuan,New,Tianyuan,Technologies,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Working Principle

The basic process of separating H2O into its elemental components occurs, when a voltage applied and a DC current flows through the electrodes submerging entire in alkaline water. Alkaline water electrolysis uses a strong aqueous alkaline solution to provide an abundance of hydroxyl ions (OH-) and minimize the electrical resistance between electrodes. When an individual half-cell electrochemical reaction occurs at each electrode:

At the anode: 4OH-→O2+2H2O+4E-

and at the cathode: 4H2O+4E-→2H2+4OH-

the overall reaction is: 2H2O→2H2+ O2

At the anode: 4OH-→O2+2H2O+4E-

and at the cathode: 4H2O+4E-→2H2+4OH-

the overall reaction is: 2H2O→2H2+ O2

With the impact of world climate change, people are eager to transition to energy, industry and transportation systems that reduce greenhouse gas emissions and realize the mode of sustainable production and consumption. Global use of hydrogen has grown rapidly over the past 10 years in many areas, and it’s increasingly gaining traction as part of the mix in a balanced energy portfolio whether as blue hydrogen with carbon-capture technology in the short term, or as green hydrogen in power plants in the near future. Sichuan New Tianyuan Technologies Co., Ltd continues to realize the possibilities and challenges of hydrogen in the development of new energy, including storage and transportation.

Applications

About Us

Company Profile

Sichuan New Tianyuan Technologies Co.,Ltd. is an export-oriented enterprise registered by multiple government departments such as industry and commerce, quality inspection, customs, and commodity inspection, focusing on the research and development of compressors and their auxiliary equipment, as well as the promotion and sales of integrated gas compression, storage, transportation, and conversion equipment. We have a marketing team composed of talents with over 20 years of experience in import and export foreign trade. Collaborate with multiple large central enterprises and private group manufacturing companies in China to leverage their respective strengths and jointly provide high-quality products to overseas customers. After unremitting efforts, the company's sales performance and market share have steadily increased year by year. The exported complete sets of equipment, containers, transport vehicles, and accessories such as compressors, compressed air tube bundle containers, CNG, and LNG have been exported to more than 30 countries and regions around the world on five continents.

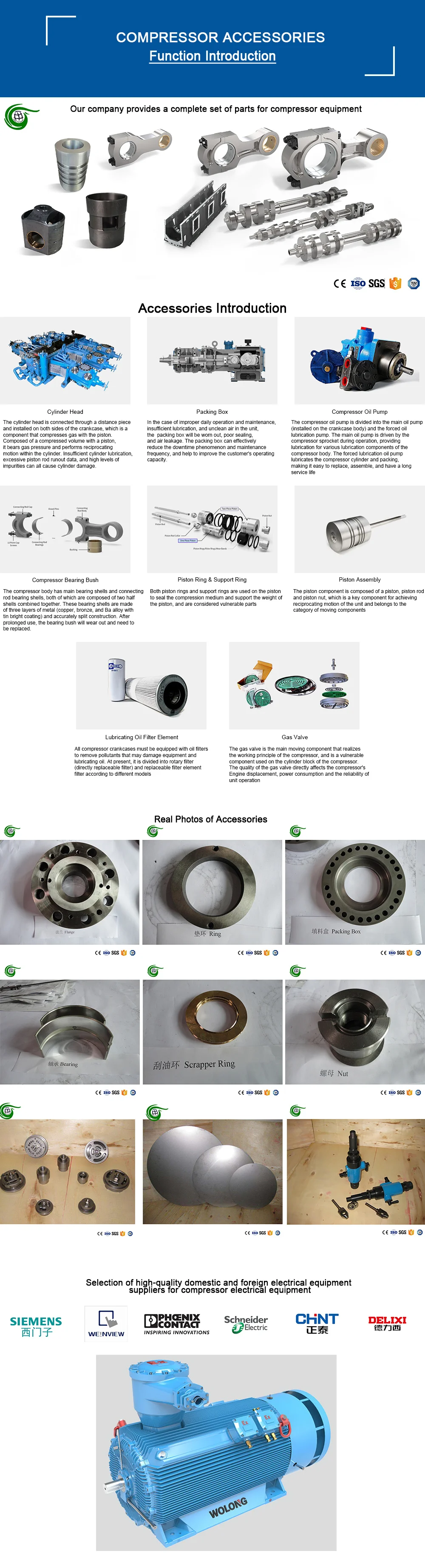

Our advantageous products and services include the following series:

A. Gas compressor

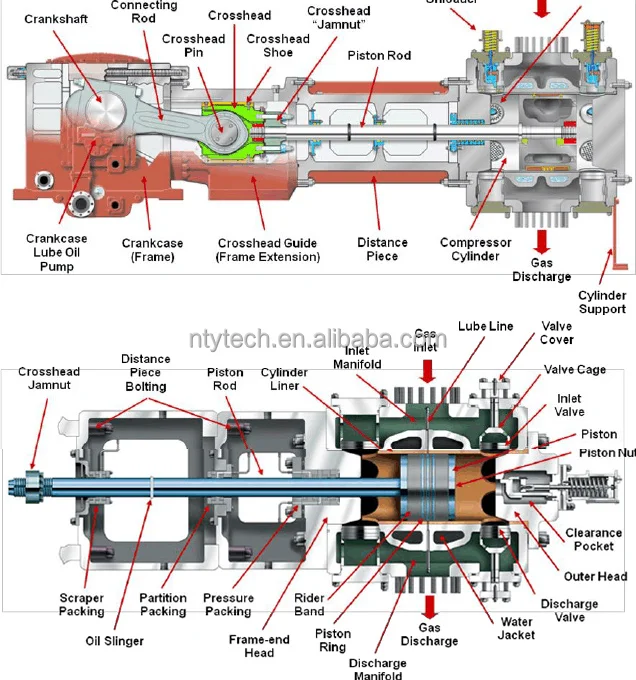

1. Various gas reciprocating piston compressors with different cooling methods and driving methods, including large displacement, medium displacement, small displacement high and low displacement, medium low, and low pressure compressors driven by water cooled, air cooled, mixed cooled motors, gas engines, diesel engines, etc;

2. Various gas diaphragm compressors, including water-cooled, air-cooled, and mixed cooling methods, are suitable for various industrial and electronic gas media such as oxygen, nitrogen, hydrogen, etc. The suction pressure can be as low as atmospheric pressure, and the exhaust pressure can be up to 700 kilograms for different purposes. They are particularly suitable for industries with small displacement gas pressurization needs such as medical oxygen production, nitrogen production, laboratory hydrogen production, helium unloading, biogas bottle filling, synthesis gas pressurization, etc;

B. Complete set of equipment and solutions for gas filling stations

1. Complete equipment for CNG refueling station, including desulfurization and dehydration devices, unloading and refueling machines, gas storage cylinder groups, pressure reducing and boosting systems, and related remote or local control systems;

2. Unloading and filling gas booster station, including unloading column, booster compressor, metering equipment, gas storage cylinder group, filling row, etc;

C. Gas containers and conveying equipment

1. Gas cylinders and gas cylinder groups, including station gas cylinder groups and mobile vehicle mounted gas cylinder groups;

2. Long tube bundle containers, including standard 20 foot and 40 foot containers with different capacity requirements;

D. A complete solution for low-temperature gas liquefaction equipment and filling stations

1. Skid mounted mobile filling stations, including integrated equipment suitable for different displacement requirements of LNG and LPG filling stations such as skid mounted box filling stations and low-temperature storage tank semi-trailers;

2. Provide a complete set of fixed filling station equipment, including low-temperature pumps, vaporizers, pressure regulating skids, liquid dispensers, storage tanks, etc.

The company provides customized services for clients' engineering projects.

Our advantageous products and services include the following series:

A. Gas compressor

1. Various gas reciprocating piston compressors with different cooling methods and driving methods, including large displacement, medium displacement, small displacement high and low displacement, medium low, and low pressure compressors driven by water cooled, air cooled, mixed cooled motors, gas engines, diesel engines, etc;

2. Various gas diaphragm compressors, including water-cooled, air-cooled, and mixed cooling methods, are suitable for various industrial and electronic gas media such as oxygen, nitrogen, hydrogen, etc. The suction pressure can be as low as atmospheric pressure, and the exhaust pressure can be up to 700 kilograms for different purposes. They are particularly suitable for industries with small displacement gas pressurization needs such as medical oxygen production, nitrogen production, laboratory hydrogen production, helium unloading, biogas bottle filling, synthesis gas pressurization, etc;

B. Complete set of equipment and solutions for gas filling stations

1. Complete equipment for CNG refueling station, including desulfurization and dehydration devices, unloading and refueling machines, gas storage cylinder groups, pressure reducing and boosting systems, and related remote or local control systems;

2. Unloading and filling gas booster station, including unloading column, booster compressor, metering equipment, gas storage cylinder group, filling row, etc;

C. Gas containers and conveying equipment

1. Gas cylinders and gas cylinder groups, including station gas cylinder groups and mobile vehicle mounted gas cylinder groups;

2. Long tube bundle containers, including standard 20 foot and 40 foot containers with different capacity requirements;

D. A complete solution for low-temperature gas liquefaction equipment and filling stations

1. Skid mounted mobile filling stations, including integrated equipment suitable for different displacement requirements of LNG and LPG filling stations such as skid mounted box filling stations and low-temperature storage tank semi-trailers;

2. Provide a complete set of fixed filling station equipment, including low-temperature pumps, vaporizers, pressure regulating skids, liquid dispensers, storage tanks, etc.

The company provides customized services for clients' engineering projects.

Process Introduction

The company has a complete set of standardized business processing processes, which can provide customers with precise and efficient communication services. This process covers the scenarios before and after the order, allowing customers to keep track of the progress and information of the order at any time.

Engineering Cases

Certifications

Customer Photos

Our Factory

Exhibition

Packaging & Shipping

There are multimodal transportation can be chosen from, such as sea transportation, air transportation, railway and land transportation, we will choose the most cost-effective transportation mode to deliver the goods. If having any special requirement, please feel free to contact us for arranging accordingly.

Commissioning

User Notice:

1. Installation: the user according to our factory provided factory foundation plan, design drawing & installation suggestion maps, brochures and other materials to ask local professional company to install.

2. Commissioning: Once the user finished installation at local, and requiring our engineers go to overseas to do commissioning kindly notify us before 20 days.

3.Training: In the commissioning process our engineers will do an on-site training, to make the user's engineers to real operate

operation and routine maintenance on-site training to ensure operators can be more familiar with relevant knowledge and skills.

operation and routine maintenance on-site training to ensure operators can be more familiar with relevant knowledge and skills.

4.Acceptance: Once completed the equipment commissioning & training. Our after-sales service engineers and users or buyers together sign acceptance report to confirm the equipment commissioning work has been completed. 5.Quality Warranty Shelf life: We promise 18-month warranty from the date of release from vendor's factory premises but not more than 12-month warranty since successful commissioning and start-up at client's project site, subject to whichever is due first. In case of any failure caused of the compressor itself due to its design, manufacture, assembly quality problem and etc.. We will provide free maintenance service in a timely manner.

6.Technical support: Each compressor package with a related gas compressor 's operation manual & maintenance

manual, detail design drawing, electric control system drawing, Manufacture test report etc. Please the user serious reading the detail before operate it. If there have any doubt for trial operation, parameter setting, failure alarm reset, etc, also welcome to email to us at www.chnequipment.com or whatsapp: +008613908096496 about your questions. We will do the best to answer you within 24 hours, and within 48 hours to provide the related solution with free technical support.

manual, detail design drawing, electric control system drawing, Manufacture test report etc. Please the user serious reading the detail before operate it. If there have any doubt for trial operation, parameter setting, failure alarm reset, etc, also welcome to email to us at www.chnequipment.com or whatsapp: +008613908096496 about your questions. We will do the best to answer you within 24 hours, and within 48 hours to provide the related solution with free technical support.

Our Service

Professional and technical personnel, serving customers online and solving problems.

1. In working days, reply within 24 hours.

2. Propose appropriate technical solutions according to customer's customized needs.

3. Customize the compressor, Logo, outer packaging, pattern, etc.

4. Each compressor will be tested before leaving the factory.

5. After the order is confirmed, the relevant technical documents will be sent

6. On-time delivery and excellent after-sales service.

7. High quality and reliable price.

Due to regional time differences, customer service online hours are:

China Beijing Time 9AM-18:00PM

London Time 2AM-11AM

Pacific Time is 1AM-10AM the next day

2. Propose appropriate technical solutions according to customer's customized needs.

3. Customize the compressor, Logo, outer packaging, pattern, etc.

4. Each compressor will be tested before leaving the factory.

5. After the order is confirmed, the relevant technical documents will be sent

6. On-time delivery and excellent after-sales service.

7. High quality and reliable price.

Due to regional time differences, customer service online hours are:

China Beijing Time 9AM-18:00PM

London Time 2AM-11AM

Pacific Time is 1AM-10AM the next day

Contact us

Tel. No. | +86 28 86799916 |

Fax. No. | +86 28 61668788 |

Website | www.chnequipment.com |

E-mail | ntytech@chnequipment.com |

WhatsApp | 008613908096496 |

Skype | Davidyzq |

(WeChat)WeiXin | ntytech |

FAQ

To have prompt and exact evaluation from factory, the following information is essential to be provided by customer while

inquiring:

1. Exact compression media: flammable, toxic, oxygen, inert gases. Preferably the gas composition can be provided;

2. Suction pressure, discharge pressure, flow capacity of compressor;

3. Control system: Requirement for manual start or full automatic control;

4. Electric parameters: Voltage, frequency, phase;

5. Any special requirement for compressed gas temperature, equipment package, configuration and etc..

We also can design piston reciprocating compressors according to clients' parameters to satisfy client's local environment and

different needs. More detailed information can be provided with further communication.

If you are interested in our products, plz contact us with no hesitation.

Sichuan New Tianyuan Technologies Co., Ltd.

inquiring:

1. Exact compression media: flammable, toxic, oxygen, inert gases. Preferably the gas composition can be provided;

2. Suction pressure, discharge pressure, flow capacity of compressor;

3. Control system: Requirement for manual start or full automatic control;

4. Electric parameters: Voltage, frequency, phase;

5. Any special requirement for compressed gas temperature, equipment package, configuration and etc..

We also can design piston reciprocating compressors according to clients' parameters to satisfy client's local environment and

different needs. More detailed information can be provided with further communication.

If you are interested in our products, plz contact us with no hesitation.

Sichuan New Tianyuan Technologies Co., Ltd.

Похожие товары

Генератор жидкого азота с низким уровнем шума

63 999,00-69 999,00 $

Портативный генератор кислорода-решение для подачи кислорода в любое время и любом месте

32 000,00-35 000,00 $

High Productivity Air Separation Plant Nitrogen

104 000,00-105 000,00 $