Машина для переработки пищевого масла машина кокосового завод по переработке подсолнечного полностью непрерывное

- Категории: >>>

- Поставщик: Henan,Oil,Press,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

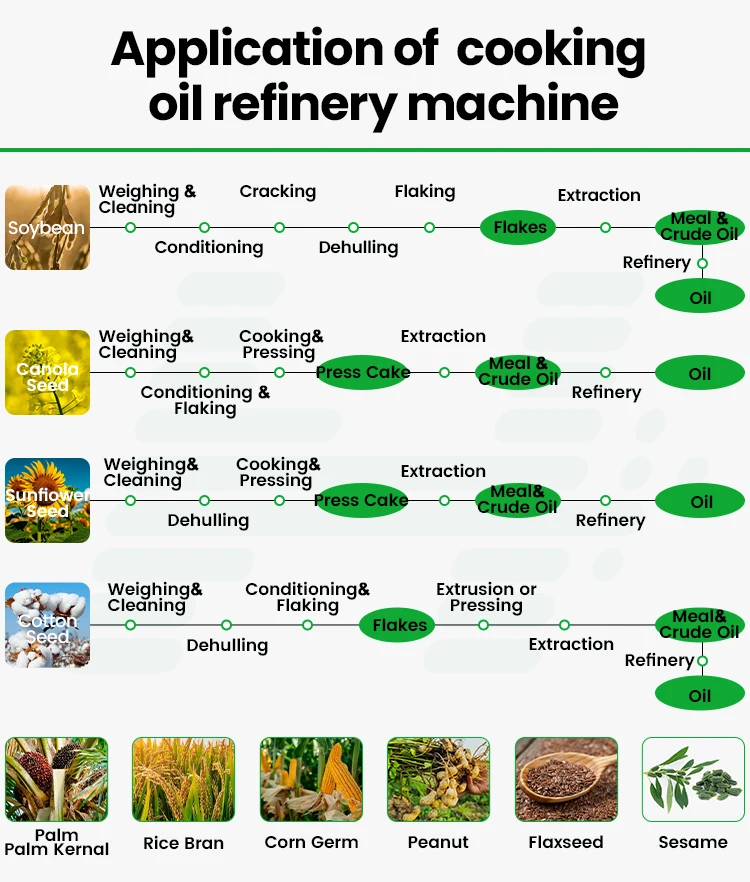

We can provide edible oil refining plant equipment with capacity ranging from 10 t/d to 2,000 t/d for soybean oil, rapeseed oil, sunflower seed oil, cottonseed oil, rice bran oil, palm oil, corn oil, peanut oil, linseed oil, animal fats and oils, chicken fat, butter, fish oil and etc.

Refining is the last step in edible oil processing. We are committed to making every drop of oil safe, healthy and nutritious. Value-adding by-products may be produced from processing stages like Degumming, Neutralization, Bleaching, Dewaxing/Winterization and Deodorization.

Worldwide, has supplied more than 500 oilseed crushing lines and more than 150 cooking oil refinery lines, including 20 cooking oil refinery production lines with capacity above 500t/d and 10 oil refinery production lines with capacity above 1,000t/d.

Refining is the last step in edible oil processing. We are committed to making every drop of oil safe, healthy and nutritious. Value-adding by-products may be produced from processing stages like Degumming, Neutralization, Bleaching, Dewaxing/Winterization and Deodorization.

Worldwide, has supplied more than 500 oilseed crushing lines and more than 150 cooking oil refinery lines, including 20 cooking oil refinery production lines with capacity above 500t/d and 10 oil refinery production lines with capacity above 1,000t/d.

Customer Stories

Refining Process

Degumming

Degumming is to remove impurities such as phospholipids, gum, protein before oil storage and transportation. Gum yielded in the degumming process can be used as raw material for producing lecithin. We provide solutions and equipment for water degumming, dry degumming, special degumming, enzyme degumming and etc.

The purpose of neutralizing is to remove free fatty acid, phospholipids, gums or solids in edible oil by using caustic soda. We offer solutions featuring higher oil yield and lower energy consumption.

Bleaching process removes coloured matters, residual pesticides, metal ions by mixing bleaching earth with edible oil. pre-bleaching process allows for better bleaching effect while using less bleaching earth.

Deodorizing

Deodorizing, the most critical step in the refining process, effectively removes odorous substances, raises smoke point of oils, improves the stability, color and quality of oils, and removes fatty acids, peroxides, polycyclic aromatic hydrocarbons, residual pesticides, etc. deodorization process retains more active nutrients while producing less harmful substances such as trans fatty acids and trichloropropanol. We can also provides fatty acid two-stage collecting system to improve the economic value.

Dewaxing

Some kinds of oils contain wax, which affects digestion and flavor and shortens shelf life in winter. Therefore it is necessary for dewaxing. We have developed a more efficient continuous crystallization technology that has a high crystallization efficiency and excellent dewaxing.

Vacuum System

Deodorization vacuum system is not only crucial to deodorization effect, but also directly related to steam consumption, sewage discharge and electricity consumption.We provide a freezing vacuum system with only 10% steam consumption and sewage discharge of a traditional vacuum system.We provide a surface condensing vacuum system with only 25% steam consumption and sewage discharge of a traditional vacuum system.

We provide one-stop edible oil production solutions |

Application

What Can We Do for You

We focus on supplying one-stop engineering service covering general layout plan, process design, R&D, equipment manufacturing, automatic control system, data integration, installation, supervision, commissioning, training and etc.

Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

Our custom solutions come from a deep understanding of your needs, and we have the capability to complete each project from the design of the initial concept to manufacturing, installation, commissioning and delivery.

About Us

Henan Oil Press Machinery Co., Ltd. is a professional company integrating R&D, design, equipment manufacturing and installation, engineering contracting, technical services and international trade. The company's business involves oilseed preparation, refining, extraction,Hydrogenation,Interesterification, as well as the pressing, refining and fractionation of palm oil and palm kernel oil.

The company has passed the ISO9001: 2000 quality management system certification and has a number of invention patents.

Customer Visits

Henan Oil Press Machinery Co., Ltd. regards quality as life, adheres to integrity, mutual benefit and common prosperity, and carries things with virtue; in accordance with the current high-standard production process, to ensure product quality and service quality.

Welcome global users to discuss cooperation.

FAQ

Q1. How to choose refining equipment?

A1: You can provide information such as planned daily output, common oilseeds, crude oil indicators, and refined oil indicators, and we will have professional engineers to design a solution suitable for you. For novices, we have a one-to-one project team to connect with you and provide a one-stop solution based on your national standards & international standards.

Q2. How to use refining equipment?

A2: We will be equipped with operation manuals & maintenance manuals, and provide remote online support. If you need, we can send technicians to the site to provide technical support.

Q3. Can you come to install the equipment?

A3: Yes, we provide equipment installation & commissioning services. Engineers can be dispatched on-site for guidance or engineering teams can be dispatched to install & debug on site according to your requirements.

Q4. What if the equipment fails and needs repair?

A4: We provide a 1-year warranty and free spare parts during the warranty period. If the equipment fails, we will provide a solution within 24 hours. If the online support cannot solve the problem, we will send engineers to solve it on site within 72 hours.

Q5. How long will it take to deliver?

A5: We have a standardized manufacturing plant, and the delivery cycle and quality are very well guaranteed. We will schedule production according to the time of signing the contract. Small equipment will meet the delivery conditions within 30 days, equipment with a daily output of 10-30 tons will meet the delivery conditions within 45 days, equipment with a daily output of 30-100 tons will meet the delivery conditions within 60 days, and equipment above 100 tons will be completed on schedule according to the contract requirements.

A1: You can provide information such as planned daily output, common oilseeds, crude oil indicators, and refined oil indicators, and we will have professional engineers to design a solution suitable for you. For novices, we have a one-to-one project team to connect with you and provide a one-stop solution based on your national standards & international standards.

Q2. How to use refining equipment?

A2: We will be equipped with operation manuals & maintenance manuals, and provide remote online support. If you need, we can send technicians to the site to provide technical support.

Q3. Can you come to install the equipment?

A3: Yes, we provide equipment installation & commissioning services. Engineers can be dispatched on-site for guidance or engineering teams can be dispatched to install & debug on site according to your requirements.

Q4. What if the equipment fails and needs repair?

A4: We provide a 1-year warranty and free spare parts during the warranty period. If the equipment fails, we will provide a solution within 24 hours. If the online support cannot solve the problem, we will send engineers to solve it on site within 72 hours.

Q5. How long will it take to deliver?

A5: We have a standardized manufacturing plant, and the delivery cycle and quality are very well guaranteed. We will schedule production according to the time of signing the contract. Small equipment will meet the delivery conditions within 30 days, equipment with a daily output of 10-30 tons will meet the delivery conditions within 45 days, equipment with a daily output of 30-100 tons will meet the delivery conditions within 60 days, and equipment above 100 tons will be completed on schedule according to the contract requirements.