LVBU-CL2210 промышленная компьютеризированная автоматическая швейная

- Категории: >>>

- Поставщик: Guangzhou,Shenghui,Sewing,Machine,Co.,Ltd.Guangzhou,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

Automatic curtain pleating sewing machine

1. Automatic calculation of the number of folds

2. Automatic calculation of fold distance

3. Automatic calculation of fold width

4.Automatic cloth folding

5. Automatic fabric conveying

6. Automatic cutting line

7. Automatic high and low pressure foot

8. Automatic sewing

2. Automatic calculation of fold distance

3. Automatic calculation of fold width

4.Automatic cloth folding

5. Automatic fabric conveying

6. Automatic cutting line

7. Automatic high and low pressure foot

8. Automatic sewing

NO. | Type of Controller | Computerized Control System for Mitsubishi Series Pattern-sewing Machine |

1 | Sewing Area | X(Lateral) Direction Y(Longitudinal) Direction SC442HG: 350(mm) x 200(mm) |

2 | Max. Sewing Speed | 2800rpm(with stitch interval below 3mm) |

3 | Stitch Length | 0.1~12.7mm, and in the control system is of version 5.0 or above, the maximum stitch length can extend to 40 mm(Min Resolution: 0.10mm) |

4 | Feed Motion of Frame | Intermittent feeding (2-shaft driven by pulse motor) |

5 | Needle Bar Stroke | 41.2mm |

6 | Needles | DP×5、DP×17 |

7 | Lift of Frame | Standard 18mm to Max. 22mm(Pneumatic type: Max. 25mm) |

8 | Intermediate Presser | Stepping Driving (Range: 0~8mm) |

9 | Lift of Intermediate Presser | 20mm |

10 | Rotating Shuttle | Double-capacity semi-rotary hook |

11 | Memory of Pattern Data | Memory/U Disk |

12 | Pause function | Stop the machine during the sewing |

13 | Scaling Up/Down Function | Allows a pattern to be scaled up/down on the X axis and Y axis independently when user sews a pattern. Ratio: 1% to 400% (0.1% per step) |

14 | Scaling Up/Down Method | Increasing / decreasing stitch length & Increasing / decreasing stitch number |

15 | Sewing Speed Limitation | 200~2800rpm(100rpm per step) |

16 | Pattern Selection Function | Pattern No. selection method |

17 | Up counter | No Count/Count of Pattern /Count of Cycle (0~99999) |

18 | Down Counter | No Count/Count of Pattern /Count of Cycle (0~99999) |

19 | Sewing Machine Motor | Servo Motor |

20 | Stop Needle at Highest Position Function | After the completion of sewing, the needle can return to its highest position. |

21 | Rated Power | 600W |

22 | Operation Temperature Range | 0℃~45℃ |

23 | Operation Humidity Range | 35%~85% (No Dew Condensation) |

24 | Line Voltage | AC 220V ± 10%;50/60Hz |

Walking trails

Enter the window width, cloth width and other data automatically calculated the fold spacing (can also be set according to their own requirements)

Walking trails.

Color touch screen with programmable arbitrary patterns.

Multi-language display, English/Vietnamese/Korean

Burmese/Turkish/Japanese/Italian

Portuguese/Spanish

Multi-language display, English/Vietnamese/Korean

Burmese/Turkish/Japanese/Italian

Portuguese/Spanish

Startup Mode 1.

Pneumatic components, automatic feeding

Startup Mode 2.

Automatic feeding, automatic discounting

2x thread volume large rotary bobbin, automatic sewing, automatic thread cutting

Motor lift medium pressure foot, program setting, automatic high and low pressure foot, the same pattern thickness can be sewn at the same time

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Buyer Reviews

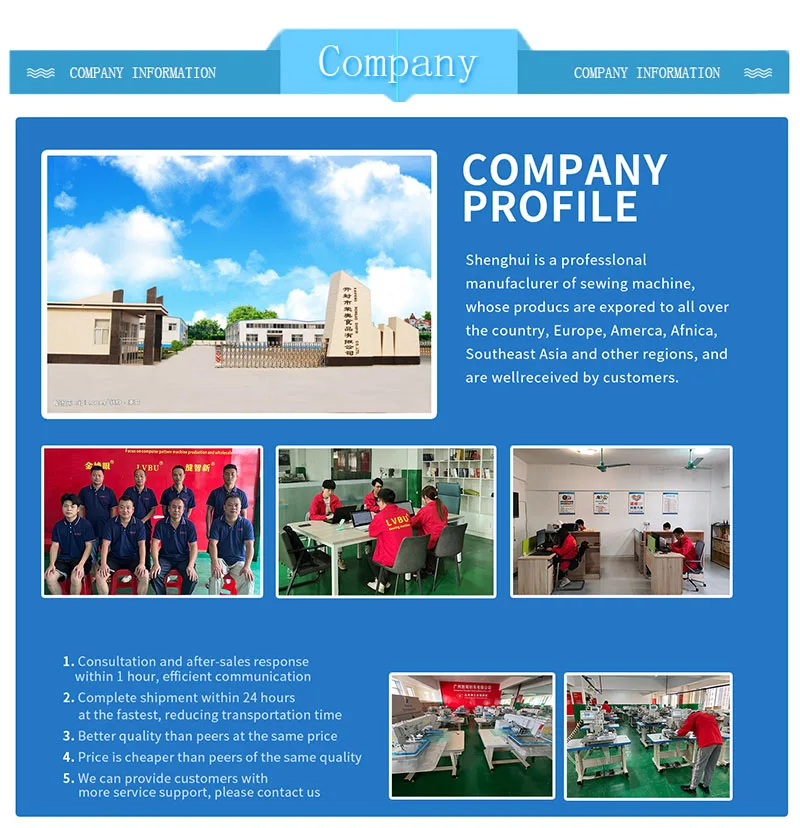

Company Profile

Certifications

Exhibition Experience

Logistics and Transportation

FAQ