Автоматическое строительное оборудование бетонный блок машина для производства кирпича

- Категории: >>>

- Поставщик: Zhengzhou,Juding,Environmental,Protection,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Semi-automatic brick making machine

XT4-35B Concrete Production Line Includes Main Machine, Cart, Its Advantage Is Less Labor, Only 2-3 People Can Complete The Operation, Easy To Operate, Can Do Different Specifications Of Solid Bricks, Hollow Bricks And Colorless Bricks, Compared With The Fully Automatic Equipment, It Belongs To The Semi-Automatic Equipment, Which Need To Spend Less Money To Meet The Production Demand.

For the block production formula as followed just for reference : 1. 8.5-10.5% cement, 30.5-39.5% sand , 51-60% crushed stone. 2. 8-10% cement, 30% flyash, 60% sand or stone powder

Why choose this machine?

1. Low cost with good quality, easy to operate. Three vibration motors are powerful.

2. Machine can make different hollow, solid blocks and pavers by changing mold, it Can meet the different needs of customers.

3. The service that we can provide, no need worry about how to install and use machine. We will provide testing video before shipping. Within one year's warranty, we supply free spare parts.

3. The service that we can provide, no need worry about how to install and use machine. We will provide testing video before shipping. Within one year's warranty, we supply free spare parts.

Quality: Due to high requirements for mechanical quality, raw materials selection, processing,assembly of industrial control over the industry standard, using the new design, quality manage-ment system, comprehensive tracking to every detail, delivery to the customer in both hardware and software are a high quality equipment.

Service: continuous and efhcient after-service for the customer support. 24 hours service with.

Model | Molding Cycle (Second) | Equipped With Power(Kw) | Class Is Produced (block) | Out put (lump/8Hours) | Plate Size (mm) | Overall Size (mm) | Weight (Kg) | Number Of Operators (Man) |

XD2-45B | 45 | 1.1 | 240*53*115/390*190*190 | 3600/600 | N/A | 900*700*1100 | 200 | 1-2 |

XD3-45B | 45 | 1.1 | 240*53*115/390*190*190 | 8000/1000 | N/A | 1100*1050*1300 | 300 | 1-2 |

XD4-35B | 35 | 6.3 | 240*53*115/390*190*190 | 15000/2400 | 850*550*30 | 1250*1350*1550 | 750 | 2-3 |

XD4-40B | 35 | 7.5 | 240*53*115/390*190*190 | 20000/3200 | 850*550*30 | 1500*1300*1800 | 1100 | 2-3 |

Features

1 It Is Controled By Plc , Very Easy To Operate . And Has High Efficiency , Reasonable Design

2 Good Adaptability Of Raw Materials, Advanced Step Vibration Molding Technology . Can Use Slag , Fly Ash And Other Industry Residue

3 It Can Make Many Kind Of Block By Changing Molds .Cater To The Market Demand To The Greatest Extent, Let The Equipment Maximize The Efficiency

4The Brick Machine Equipment Adopts The Industrial Plc Control System Of Japan Is Mitsubishi(Germany Siemens)

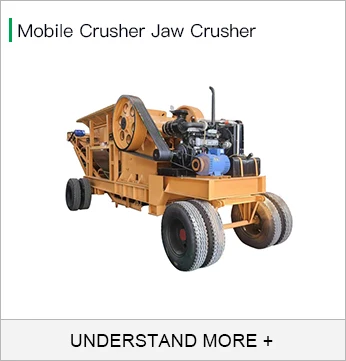

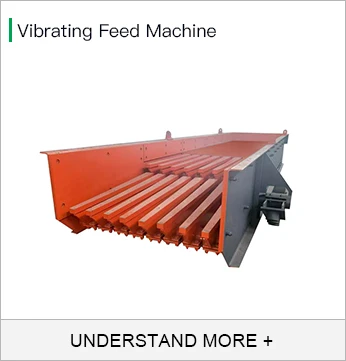

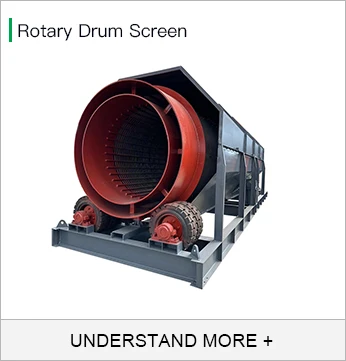

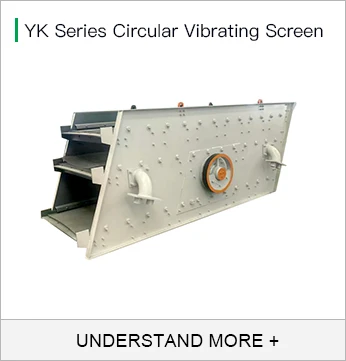

Zhengzhou Juding Environmental Protection Equipment Co., Ltd. is an enterprise focusing on the research and development, manufacture, sales and service of mining machinery equipment and automation equipment. The main products are: mobile crushing plant, sand making machine, sand washing machine, all kinds of crushers, vibrating screen, feeder and related accessories. The products are widely used in mining, building materials, highway, railroad, bridge, chemical industry, metallurgy, refractory materials and other industries, and are exported to Vietnam, North Korea, Central Africa, the Middle East and other countries and regions. The company adheres to the enterprise tenet of “integrity, innovation, enterprise and win-win”, takes the market as the guide and customer satisfaction as the purpose, pursues excellence and continuous improvement.

Our Service

Before order:

Answering Customers' Questions: According to our customer's question by email or telephone, we will provide a patient customer' service.

For example: In the beginning of communication, customers will consulting some details about our pellet machine or our company, and we will provide a professional answers for customers understand us better solution just for our customers condition.

Design Drawings: We will design drawings for customers' reference.

Making offer: According to customers purchase quantity, making a good offer with details solutions.

Answering Customers' Questions: According to our customer's question by email or telephone, we will provide a patient customer' service.

For example: In the beginning of communication, customers will consulting some details about our pellet machine or our company, and we will provide a professional answers for customers understand us better solution just for our customers condition.

Design Drawings: We will design drawings for customers' reference.

Making offer: According to customers purchase quantity, making a good offer with details solutions.

After order:

Delivery Time: After signing the contract and receiving the deposit, the production will take 15~20 working days.

Order Tracking: After the deposit received, there will be a professional team tracking the order from production to package and shipment.

After-sale Service:

Warranty Period: We provide 12 month warranty for main body. Within 12 month, there is any quality problem with the main body(not including the wearing parts), we will arrange our professional engineers to provide requirement service.

Installation Service:

If customers don't need our engineers for installation, we will provide Remote Advisory Services. Also we could arrange engineers to provide installation service if customer need.

Delivery Time: After signing the contract and receiving the deposit, the production will take 15~20 working days.

Order Tracking: After the deposit received, there will be a professional team tracking the order from production to package and shipment.

After-sale Service:

Warranty Period: We provide 12 month warranty for main body. Within 12 month, there is any quality problem with the main body(not including the wearing parts), we will arrange our professional engineers to provide requirement service.

Installation Service:

If customers don't need our engineers for installation, we will provide Remote Advisory Services. Also we could arrange engineers to provide installation service if customer need.

A: We are factory.

Q2: Where have your products been exported to?

Q2: Where have your products been exported to?

A:Our products have been sold to South Asia, Africa, South America and the Middle

East.

Q3:How can I help my customers install their equipment?

A:Our senior engineers will video guide you through installation,commissioning and initial production.

Q4: What is the availability of wearing parts?

A:We offer our customers wearing parts at the most favourable prices. If there is a problem that you cannot handle, we will send

atechnician to your location, so you will be responsible for all related costs.

Q5: What about after-sales service?

A:All products are guaranteed for 12 months.

East.

Q3:How can I help my customers install their equipment?

A:Our senior engineers will video guide you through installation,commissioning and initial production.

Q4: What is the availability of wearing parts?

A:We offer our customers wearing parts at the most favourable prices. If there is a problem that you cannot handle, we will send

atechnician to your location, so you will be responsible for all related costs.

Q5: What about after-sales service?

A:All products are guaranteed for 12 months.