Заводская цена винтовой пресс для пальмового

- Категории: >>>

- Поставщик: Anyang,Gemco,Energy,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Factory Price Screw Palm Oil Press Machine for Mini Small Edible Palm Fruit Oil Expelling/Milling/Making/Processing Production

GEMCO is a reliable manufacturer of palm oil extraction machine including screw palm oil machine, palm oil processing machine, palm kernel oil processing machine, palm oil refinery machine, automatic complete palm oil production line and solvent oil extraction machine. Over 10 years of experience in equipment manufacturing and project constraction has proved our strong ability and great product quality.

Oil palm is one of the most important tropic oil seed plants in the world. The oil rate in oil palm is very high: generally 46~50% in the fresh pulp , and 50~55% in palm kernel. Palm oil is extracted from fresh fruit bunches (FFB) by a mechanical process, we can provide the palm oil extraction machine from 10 ton to 3000 tons per day capacity with low cost and energe-saving.

--------------------------------------------------------------------

⭐Palm Oil Expeller Machine (Oil Squeezer) for sale: Includes small scale screw palm oil press machine and industrial expeller oil machine for large scale production. It can be widely applied to make oil from fresh palm fruit and palm kernel. (Capacity Range: 0.8ton~20tons/day small oil milling plant, medium-sized oil processing plant)

⭐Fresh Palm Fruit Oil Mill Line (red palm oil extraction machine): We provides 1-50ton/day palm oil making machines to extract oil from fresh fruit bunches of oil palm. Main Machinery includes steriliser, digester, stripper machine, screw press, nut/fiber separator, oi filling/bottling machine etc. All our projects are designed based on different capacity and your specific situation and requirments.

⭐Palm Kernel Oil Mill Plant (PKO): Offer customized both 1-20ton/day small palm kernel oil extraction machine, palm oil refining machine and 20-500ton/day oil manufacturing plant for making oil from palm kernel/seeds. The main palm oil processing line includes full pressing, solvent extraction and pre-pressing solvent extraction. The main types of edible oil processing process includes oil squeezing/pressing, solvent extraction, pre-pressing & solvent extraction, oil refining, oil filtration, oil purification/clarification, oil fractionation.

⭐Palm Oil Refinery Plant (physical refining of crude palm oil): Edible oil refinery plant (refining machine) is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality palm oil and palm kernel oil produces. According to the refining scale, it is divided into 1-10ton/day Batch Type Small/Mini Oil Refinery Plant, 10-50 ton/day Semi-Continuous type Crude Oil Refinery Plant and 30-100T Continuous Oil Refinery Plant (includes steainless steel refining machines).

⭐Fresh Palm Fruit Oil Mill Line (red palm oil extraction machine): We provides 1-50ton/day palm oil making machines to extract oil from fresh fruit bunches of oil palm. Main Machinery includes steriliser, digester, stripper machine, screw press, nut/fiber separator, oi filling/bottling machine etc. All our projects are designed based on different capacity and your specific situation and requirments.

⭐Palm Kernel Oil Mill Plant (PKO): Offer customized both 1-20ton/day small palm kernel oil extraction machine, palm oil refining machine and 20-500ton/day oil manufacturing plant for making oil from palm kernel/seeds. The main palm oil processing line includes full pressing, solvent extraction and pre-pressing solvent extraction. The main types of edible oil processing process includes oil squeezing/pressing, solvent extraction, pre-pressing & solvent extraction, oil refining, oil filtration, oil purification/clarification, oil fractionation.

⭐Palm Oil Refinery Plant (physical refining of crude palm oil): Edible oil refinery plant (refining machine) is to remove all kinds of impurities, and make the least damage to the neutral oil and natural antioxidants (tocopherol), so as to produce high quality palm oil and palm kernel oil produces. According to the refining scale, it is divided into 1-10ton/day Batch Type Small/Mini Oil Refinery Plant, 10-50 ton/day Semi-Continuous type Crude Oil Refinery Plant and 30-100T Continuous Oil Refinery Plant (includes steainless steel refining machines).

______________________________________________________________________________________________________________________

Palm oil mill process is quite different from other oil seeds processing. The manufacture of crude palm oil involves a series of processes starting with harvesting fresh fruit bunches from the plantations and ending with crude palm oil storage. Through sterilizing, threshing, mashing and expelling, crude palm oil will be pressed out in palm oil pressing machine (screw oil press). Each station of palm oil mill uses different methods and machines. After purifying and refining, the refined palm oil can be exported as a popular kind of healthy and edible oil.

⭐Plam Fruit Harvesting: The initial process in palm oil mill is reaping the palm fruit bunches.

⭐Palm Fruit Sterilizing: Through fruit reception system, the palm fruit bunches will be transported to the next process - Sterilizing Station. The disinfection process utilizes steam or water to sterilize the fresh palm fruits. This process likewise stops enzymatic responses that prompt oxidation and upsets the cells which are found in the mesocarp, so that to improve the oil extraction efficiency and final oil product quality. Dry sterilizing means roasting or smoking the fruits, while wet process means boiling or steaming the fruits. If choose dry process, the palm fruits are separated first, and then sterilized. If use wet process, the fruits are sterilized before threshing.

⭐Palm Threshing: In the threshing process of palm oil mill. The fruitlets are separated from the whole bunches by use of stripper machine. Threshing is generally mechanical in large palm oil mill by use of thresher, which rotates or vibrates to remove the fruits from the bunch. Pam fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel.

⭐Digesting: Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

⭐Palm Fruit Sterilizing: Through fruit reception system, the palm fruit bunches will be transported to the next process - Sterilizing Station. The disinfection process utilizes steam or water to sterilize the fresh palm fruits. This process likewise stops enzymatic responses that prompt oxidation and upsets the cells which are found in the mesocarp, so that to improve the oil extraction efficiency and final oil product quality. Dry sterilizing means roasting or smoking the fruits, while wet process means boiling or steaming the fruits. If choose dry process, the palm fruits are separated first, and then sterilized. If use wet process, the fruits are sterilized before threshing.

⭐Palm Threshing: In the threshing process of palm oil mill. The fruitlets are separated from the whole bunches by use of stripper machine. Threshing is generally mechanical in large palm oil mill by use of thresher, which rotates or vibrates to remove the fruits from the bunch. Pam fruits will be conveyed to palm oil presser to get CPO. Palm bunch can be used as fertilizer or fuel.

⭐Digesting: Before extracting oil, the palm fruits need to be crushed in digester machines. To augment oil yield, the fruit pulp is also warmed in this process. The mesocarp and nuts can be squeezed together in palm oil making/pressing machine. But if you plan to make Grade A Palm Oil, the palm nut/kernel should be removed before oil pressing section.

⭐Oil Pressing: The pulp is then pressed, which bursts the oil-containing cells, releasing the palm oil. There are several types of oil making machines that may be used to press the fruit pulp, including manual presses, hydraulic presses, and screw presses. The screw press is the most commonly used palm oil making machine in both small and large scale palm oil manufacturing plant due to its high oil extraction rate.

⭐Palm Oil Clarification: The purpose of clarification in palm oil manufacturing process is to remove impurities. The final crude palm oil will be storage in bulk in a tank.

⭐Palm Kernel Recovery: After palm oil expelling, the solids parts discharged from the screw press is mixture of fiber and nuts. In palm kernel recovery plant, the nuts and fiber are separated by physical means. The nuts are sent to palm kernel crushing and solvent extraction plant to make palm kernel oil, while the fiber is used as biomass fuel in boiler on-site.

We will choose the palm oil mill process according to the different requirements of different customers. Both technical and economic effects are taken into account while plan the palm oil mill process, so that to build the best palm oil mill plant.

We will choose the palm oil mill process according to the different requirements of different customers. Both technical and economic effects are taken into account while plan the palm oil mill process, so that to build the best palm oil mill plant.

______________________________________________________________________________________________________________________

We are an international manufacturer, supplier and exporter of vegetable oil mill machinery and cooking oil mill plant. We can not only offer small scale cooking oil making machine(screw palm oil press), mini oil mill plant for starters to easily enter into the profitable oil industry, but also boast strong strengths to undertake customized complete turnkey projects of fully automatic oil mill plant and vegetable oil refining line.

⚙️Strong Project Engineering Capability: We are the large grain&oil machinery manufacturer integrating R&D, design, manufacturing, installation and after-sales service. The main technical team consists of professional technicians and process engineers.. Thanks to the independent technology development department -- "Technology R&D Center", we can customize technical solutions according to customer needs.

⚙️Business Cooperation All Over the World: We have sales, service and engineering operations around the world, cooperate with more than 50 countries, while providing localized services.

⚙️Advanced Processing Equipment, Quality Assurance: Imported domestic and foreign CNC equipment with high processing precision. Each process in the production workshop is strictly trained according to standardized criteria, and the chief engineer personally manages the process during the production process to ensure product quality.

⚙️Strong Project Engineering Capability: We are the large grain&oil machinery manufacturer integrating R&D, design, manufacturing, installation and after-sales service. The main technical team consists of professional technicians and process engineers.. Thanks to the independent technology development department -- "Technology R&D Center", we can customize technical solutions according to customer needs.

⚙️Business Cooperation All Over the World: We have sales, service and engineering operations around the world, cooperate with more than 50 countries, while providing localized services.

⚙️Advanced Processing Equipment, Quality Assurance: Imported domestic and foreign CNC equipment with high processing precision. Each process in the production workshop is strictly trained according to standardized criteria, and the chief engineer personally manages the process during the production process to ensure product quality.

______________________________________________________________________________________________________________________

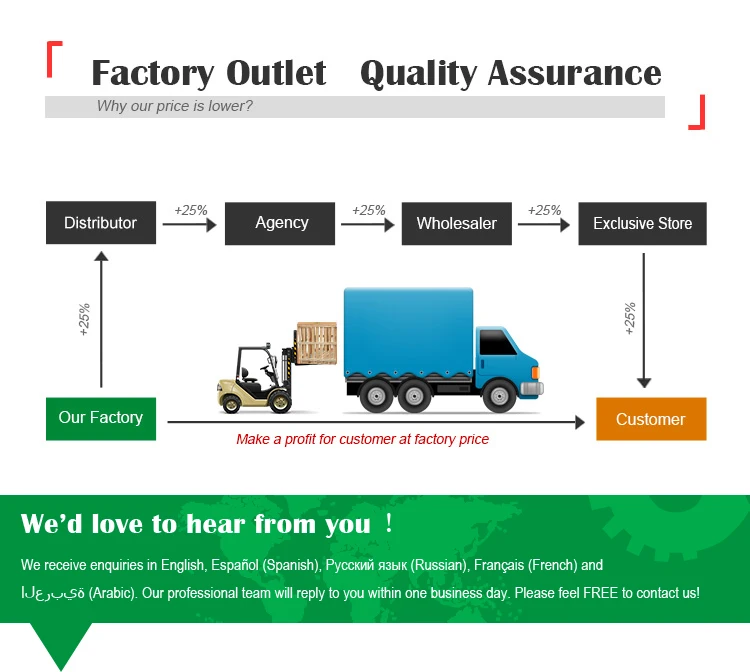

We are offering the factory price oil expeling machines(palm oil press machine) and providing complete edible oil production line(palm oil expeller) in many countries around the world, including Mexico, Panama, Pakistan, Thailand, Kazakhstan, Malaysia, Sri Lanka, Philippines, Uzbekistan, Chile, Brazil, Jamaica, Nigeria, Argentina, Ghana, Ethiopia, Russia, Australia, USA, Cameroon, Somalia, Uganda, UK, Moldova etc.

If you have any other requirement on the screw palm oil press,just feel free to contact us to get more details of palm oil press machine and enjoy the lated promotion wholesale price!

~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~