Телескопическая гидравлическая козловая система 50 80 100 120 150 200 тонны 220 250 300 350 400 600 900 тонный гидравлический козловой кран для

- Категории: >>>

- Поставщик: Beijing,Yuanda,Heavy,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Telescopic Gantry Lift System 50 80 100 120 ton 150 200 300 500 600 900 1000 ton Hydraulic Gantry Crane Hydraulic Gantries

Hydraulic Gantries

Hydraulic Gantry Crane is a combination of two or more legs (power towers) and an overhead beam or girder construction. Hydraulic gantries have hydraulic legs, which enables them to perform lifts by extraction of their legs - which could be built over the foundation. Hydraulic gantries are a safe, efficient way to lift and position heavy loads in applications where traditional cranes will not fit and permanent overhead structures are not an option. When used with rail systems, hydraulic gantries are placed on skid tracks to provide a means for moving and placing heavy loads. Hydraulic gantries are a cost effective solution for many lifting and rigging applications.

Main Features:

Hydraulic gantry crane 100t for sale/200t hydraulic gantry crane manufacturer and supplier in China

• Super Lift with best-in-class control system and comparable capacity utilizing telescopic cylinders offered in 2 or 3 stages.

• Super Boom Lift with capacities up to 1,200 tons and 3-stage lifting capability through the boom structure .

• Self-contained hydraulics

• Wireless Intellilift controls

• Synchronous lifting and lowering

• Self-propelled wheels or tank rollers with synchronized travel.

Hydraulic gantry crane system components and spare parts: Header Beam, Skid Track, Side Shift(Lifting Anchors). The rail system is available in two standard lengths, 10 feet and 20 feet and reduce ground bearing pressure. Custom lengths available on request.

The following technical parameters is for the common size(Most of clients need). Pls check the rated load, the span and the lifting height is suitable for your requirements.

Retracted Height (M) | 1st Stage Capacity (Tons) | 1st Stage Height (M) | 2nd Stage Capacity (Tons) | 2nd Stage Height (M) |

3.023 | 120 ton | 7.315 | - | - |

3.454 | 200 ton | 8.382 | - | - |

3.023 | 220 ton | 7.214 | 145 | 9.144 |

3.023 | 230 ton | 6.833 | 218 | 8.534 |

3.505 | 300 ton | 8.103 | 109 | 10.211 |

3.556 | 400 ton | 8.382 | - | - |

4.267 | 450 ton | 10.363 | - | - |

3.556 | 500 ton | 7.849 | 331 | 9.754 |

4.267 | 550 ton | 9.754 | 331 | 12.192 |

3.454 | 600 ton | 7.442 | 426 | 9.144 |

4.217 | 650 ton | 9.652 | 426 | 12.040 |

3.455 | 800 ton | 7.061 | 600 | 8.534 |

4.268 | 850 ton | 9.448 | 600 | 11.734 |

4.42 | 1100 ton | 7.06 | 790 | 9.448 |

Note: Lift capacities are maximum and assume four lift housings equally loaded. The weight of lift beams and rigging must be deducted in arriving at live load capacity. Lift Heisht Measurements assume fully extended power manual stage. | ||||

And the dimension and capacity all can be customized made as you need, even if you do not know the specific data clearly, pls tell us the problem you meet now and the objects you need to lift. Then our engineer team can suggest a best design and solution for you.

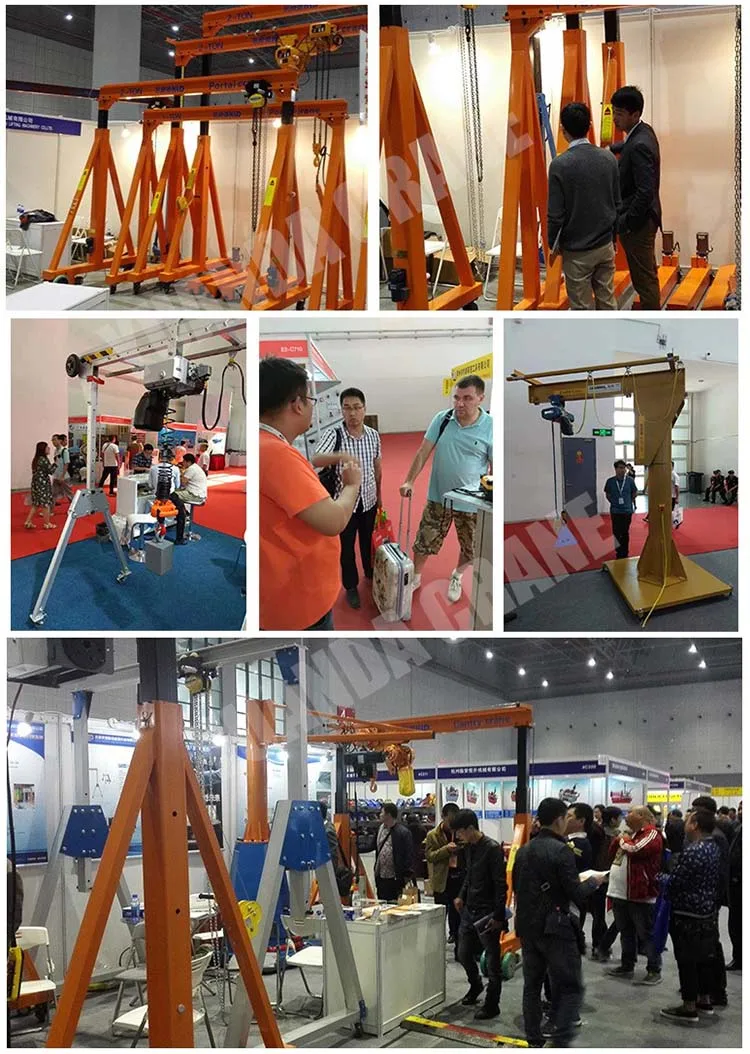

Beijing Yuanda Heavy Machinery Equipment Co. Ltd is a professional large-scale manufacture of all types of hoisting cranes and machinery equipments. Our company was established in 2009 located in Beijing which is capital of China. Our company has the professional technical teams to provide you the best solution if you want the customized products. We have always focused on research, development and innovation. Our watchword is "Providing the best product with the most competitive price; not only providing the professional pre-sale service but also providing the best after-sale service.We have over 20 years experience in R&D design. Our main products are gantry crane, jib crane, bridge crane, handing equipment, industrial manipulator, conveyors, industrial machineries and some other new products with modern technology.We look forward to your coming and hope our long good relationship.

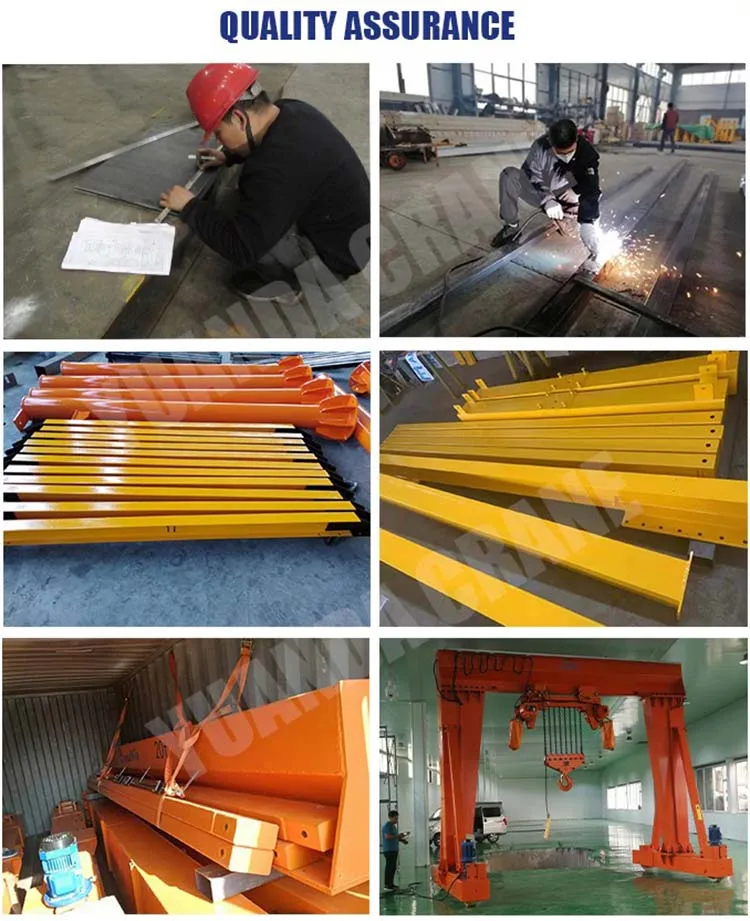

Quality assurance — is a means of preventing defects and mistakes in manufactured products :

At YUANDA, we are fully committed to providing quality products and services through strict quality control.

1. Strict weld inspection process

2. Strict size control for each parts

3. Strict production processing and workmanship control ,QC inspection control

4. Strictly polished after the welding

5. Before painting, cover and protect some parts ,ensure paint quality

6. Before delivery ,pre-assembled & test whole crane ,ensure crane not dimension mistake and no quality problems