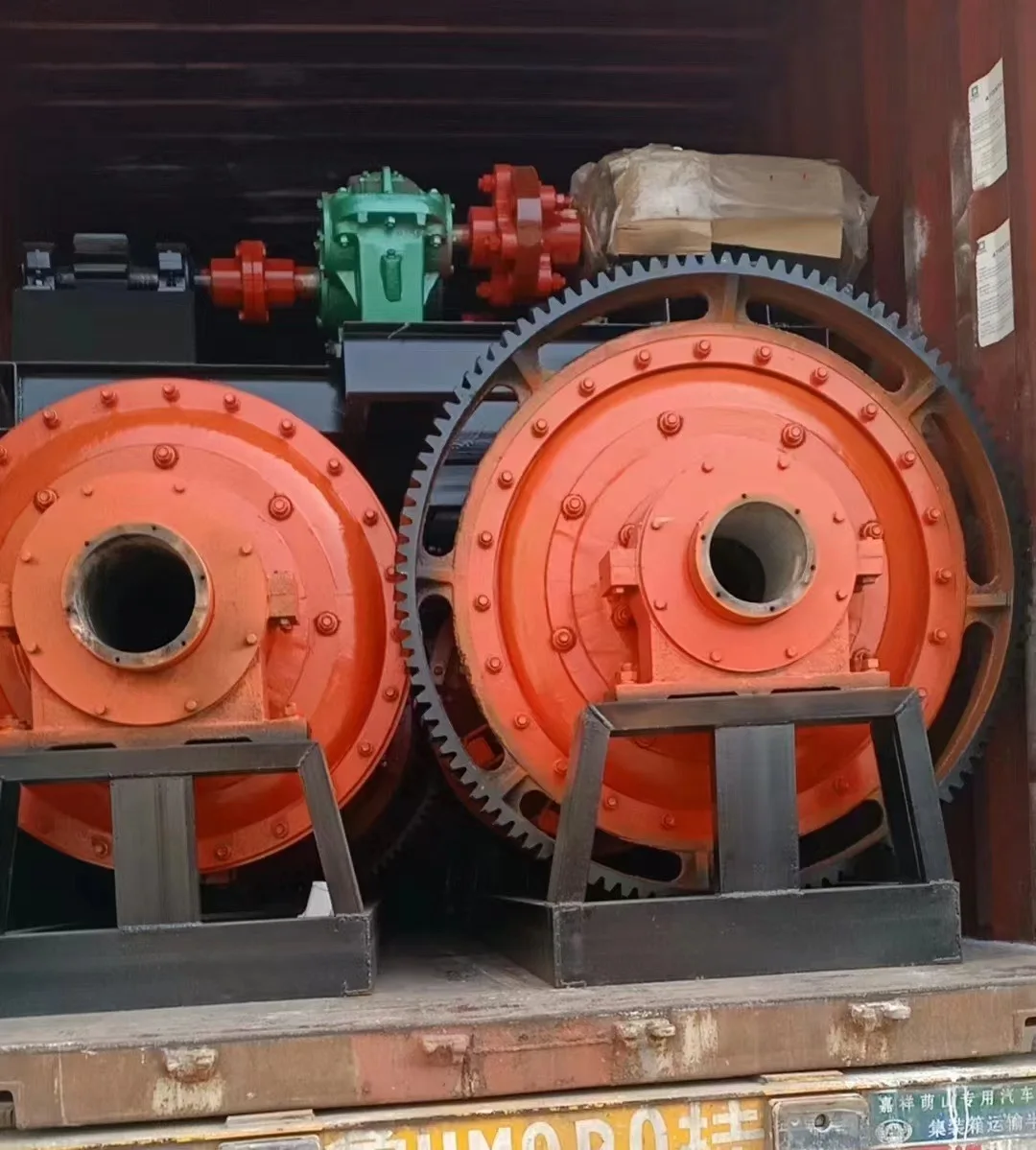

Машинка для производства шлака

3 500-3 980 $

Поделиться:

Model | Cylinder Rotating Speed:(c/mln) | Balls Weight:(t) | Feeding Size:(mm) | Discharging Size:(mm) | Capacity:(t/h) | Power: ( kw ) |

900×1800 | 38 | 1.5 | ≤20 | 0.075-0.89 | 0.65-2 | 18.5 |

900×3000 | 38 | 2.7 | ≤20 | 0.075-0.89 | 1.1-3.5 | 22 |

1200×2400 | 35 | 4.6 | ≤25 | 0.075-0.6 | 1.6-5.8 | 37 |

1200×4500 | 35 | 5.5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 |

1500×3000 | 29 | 9 | ≤25 | 0.074-0.4 | 2-7 | 75 |

1500×5700 | 29 | 17 | ≤25 | 0.074-0.4 | 3.5-6 | 110-130 |

1830×4500 | 25.4 | 15 | ≤25 | 0.074-0.4 | 4.5-12 | 155 |

1830×6400 | 24.1 | 21 | ≤25 | 0.074-0.4 | 6.5-15 | 210 |

1830×7000 | 24.1 | 23 | ≤25 | 0.074-0.4 | 7.5-17 | 245 |

2100×4500 | 23.7 | 24 | ≤25 | 0.074-0.4 | 8-43 | 245 |

2100×7000 | 23.7 | 26 | ≤25 | 0.074-0.4 | 8-48 | 280 |

2200×4500 | 21.5 | 27 | ≤25 | 0.074-0.4 | 9-45 | 280 |

2200×6500 | 21.7 | 35 | ≤25 | 0.074-0.4 | 14-26 | 380 |

2400×3000 | 21 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 |

2400×4500 | 21 | 23 | ≤25 | 0.074-0.4 | 30-50 | 245 |