Q1: Are you manufacturer or trade company?

A1: We are original manufacturer with One-stop service has more than 40 years history in China.

Q2: What's your major products?

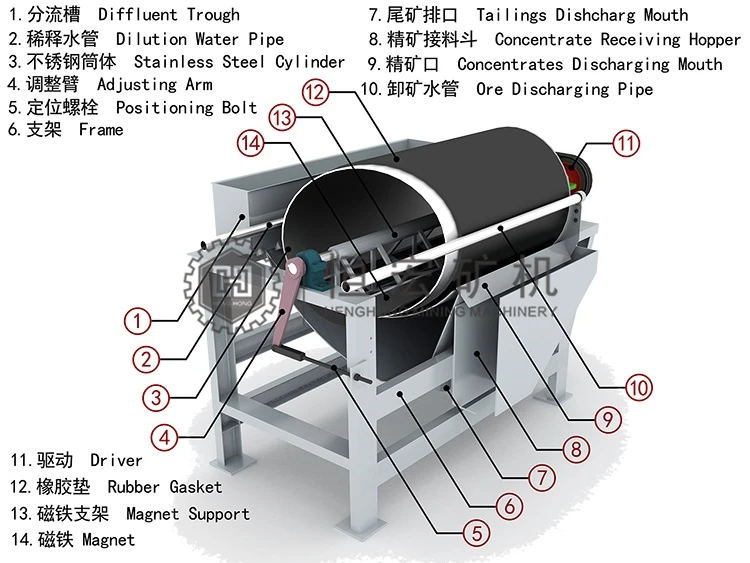

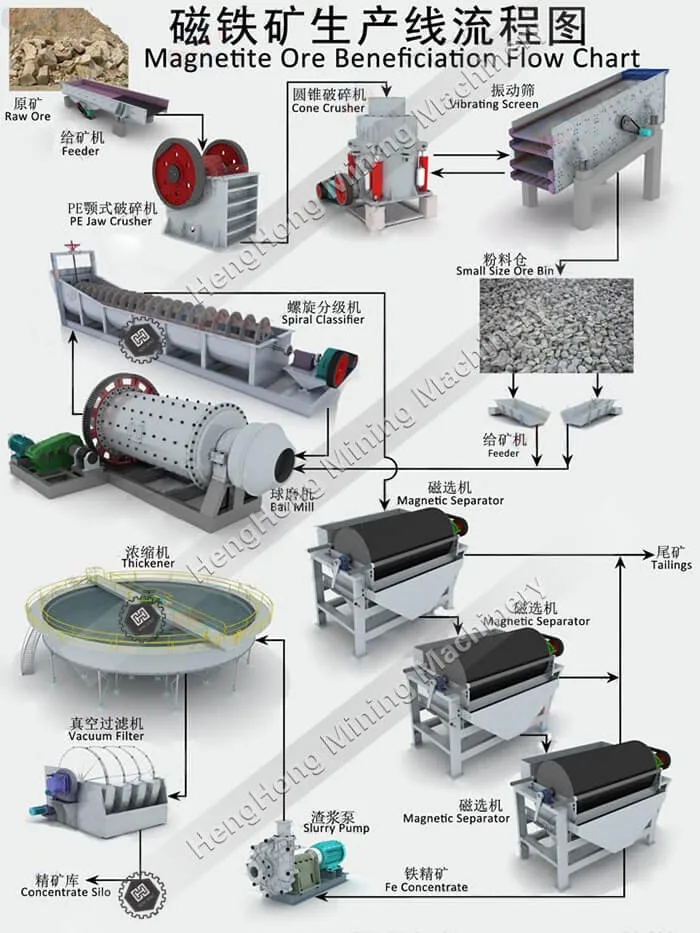

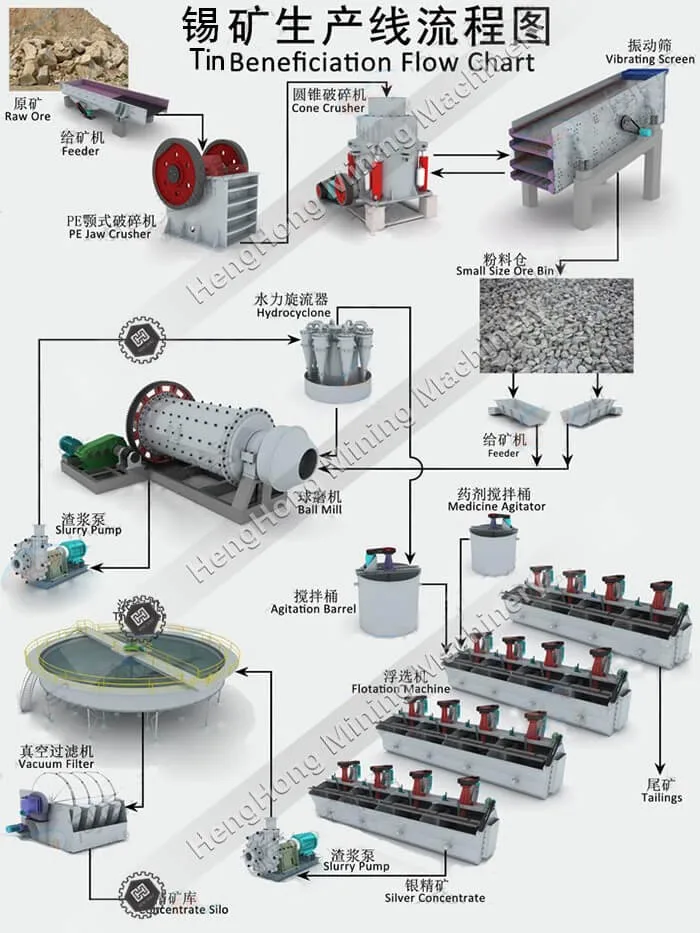

A2: Our products have been sold to all over the world, they are ball mill, wet pan mill, jaw crusher, hammer crusher, shaking table, centrifugal concentrator, jig machine, spiral chute, flotation machine, magnetic separator, sand washing machine, gold smelting furnace, belt conveyor, slurry pump etc.

Q3: How will you help the customer to install the equipment?

#1 Our senior engineer will supply installation and training service on-line or on-site.

#2 We have engineer in Southeast Asia and Africa, we can supply 7*24 service.

Q4: What about after-sale service?

A4: 18 months warranty for all kinds of products.

Q5: How long is your delivery time?

A5: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q6: What about the payment method?

A6: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

Q7: How to get the free solution and quotation?

A7: Please send inquiry to us on Alibaba, or please scan and add us as below picture, leave your whatsapp or email adress.our sales manager will contact you ASAP.