3 175 фрезы RCF PCB Маршрутизатор бит для ЧПУ

- Категории: >>>

- Поставщик: Xiamen,HJ,Carbide,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Product Description

RCF series have diamond cut geometry and suitable for contouring on most general PCBs and Halogen-free PCBs. The range offers good swarf/chip evacuation and long-life.

Product Name | RCF router bit |

Material | Tungsten carbide |

Shank Dia | 3.175mm |

Over length | 38.10mm |

Mill Dia | 1.0-3.175mm |

Flute Length | 7.0-12.0mm |

Used | Routing machine |

Dimension | Parameters | ||||

Mill Dia (mm) | Flute Length (mm) | Spindle Speed (Krpm) | Table Feed (mm/s) | ||

1.0 | 7.0 | 40-45 | 5-7 | ||

1.1 | 7.0 | 42-46 | 8-12 | ||

1.2 | 7.0 | 41-45 | 8-14 | ||

1.3 | 7.0 | 38-42 | 8-14 | ||

1.5 | 8.0 | 31-35 | 10-16 | ||

1.6 | 8.0 | 28-33 | 11-16 | ||

1.8 | 10.0 | 26-30 | 12-18 | ||

1.9 | 10.0 | 25-29 | 12-18 | ||

2.0 | 10.0 | 24-29 | 11-16 | ||

2.2 | 10.0 | 23-27 | 16-20 | ||

2.4 | 10.0 | 22-26 | 16-20 | ||

2.5 | 10.0 | 21-25 | 16-20 | ||

3.0 | 10.0 | 18-22 | 16-20 | ||

3.175 | 12.0 | 18-22 | 16-20 | ||

RCF0.6x4.5F Increased the quality of the edge

Name | PCB diamond tooth milling cutter |

Specifications | RCF0.6x4.5F |

Processing material | GHPL820WDFI, SP board |

Cutting speed | 55krpm, 2.0mm/s |

Processing function | Finishing |

Cutting method | Inner groove finishing |

Test background | The proportion of burrs, bumps, and sawtooth defects on the appearance of the customer’s SP board is 100%, and need to be improved. |

Cutting effect | Competitive products have burrs, serrations, and irregularities on the edge of the board, and the defect ratio is 100%; the special F-shaped knife design is adopted to improve the quality of edge processing without defects. |

Fish tail type is standard router. Flat-end and drill types can be provided upon the requirement.

Up draft type is supplied as standard. Down draft can be provided upon the requirement.

Ring Setting

Company Profile

HJ Carbide is a high-tech enterprise integrating R&D, production and sales. Expert in the ultrafine cemented carbide research and development.

We specialized in designing and manufacturing of precision cutting tools, including cemented carbide rods, Solid Carbide end mill cutter, carbide drill bits, carbide turning inserts and some special precision cutting tools.

Our company is based on our firm commitment to providing the premium cutting tools and highest levels of customer service for global customers in the aerospace, automotive, medical, mold making and 3C industries who are looking

for comprehensive cutting tool solutions.

Coupled with a range of advanced manufacturing equipment, streamlined processes and testing devices, our team of seasoned professionals is large enough to produce the cutting tools to an exceptionally high standard. All our cutting tool products are ISO9001 and OHSAS18001 compliant. The reliable quality of products is highly appreciated by our customers worldwide.

Whether you are a distributor looking for cooperative partner or an end user looking for custom cutting tools for your specific machining applications, We are a trustworthy source for you.

Certifications

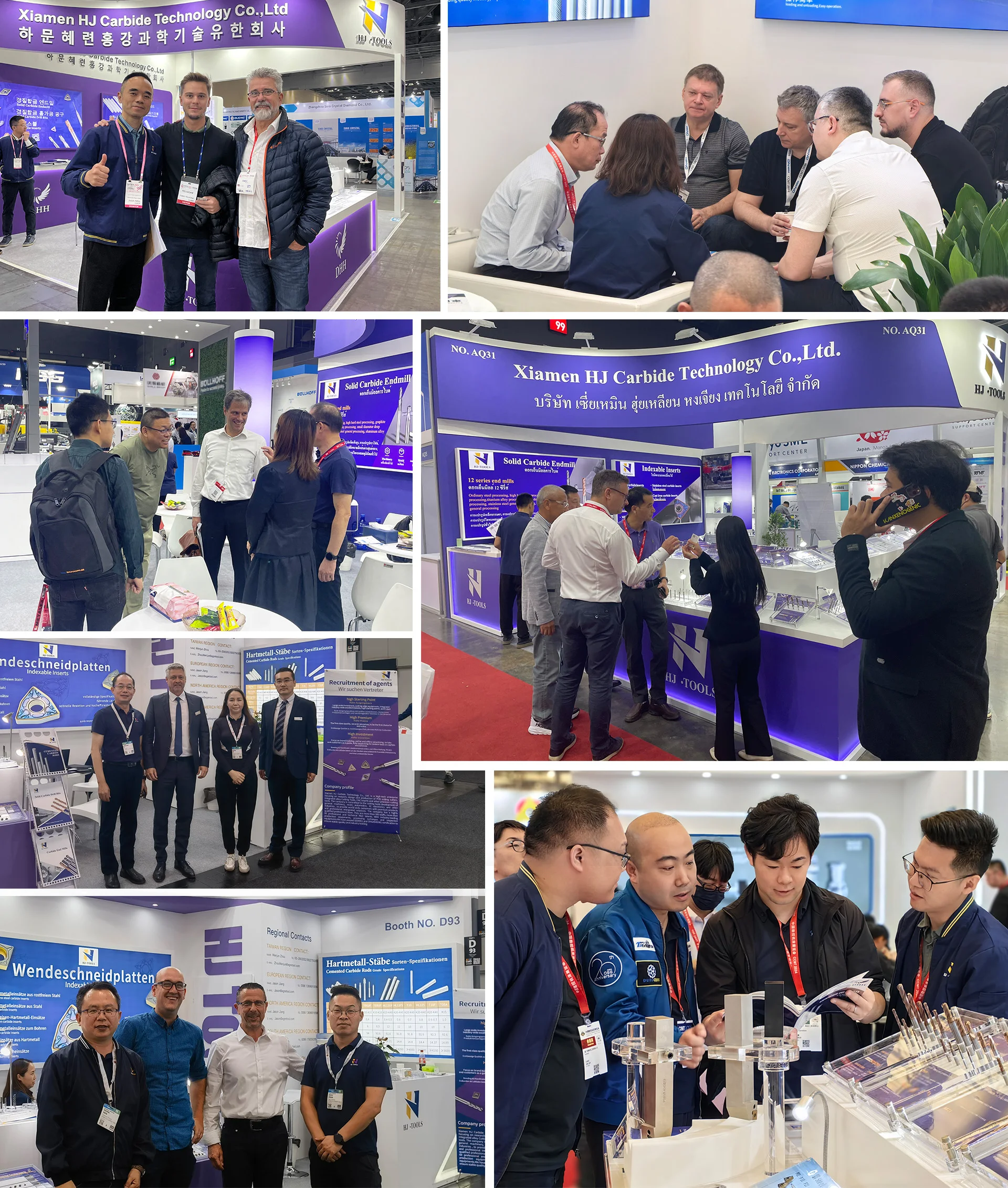

Exhibition

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

FAQ

Q: Are you a manufacturer?

A: Yes, We are a professional cutting tools manufacturer and has its own factory based in Xiamen. We produce in-house the carbide rods, end mills, drill bits, indexable inserts, etc.

Q: Can you supply with drawing or on an ODM basis?

A: Yes, We can supply customized products.

1) We can produce according to your drawings;

2) We can supply goods with medium-sized packaging without our logo, then you can repack at your side with your brand packaging;

3) If volume is big, we can pack at our side with your brand packaging.

Q: Why we cooperate with you?

A: There are some reasons:

1) We are a company with adequate production machines, inspection instruments, which can supply good quality products with reasonable price;

2) We enter new cutting tool area with skilled personnel who have worked in industry-renowned companies for years, which found a basis for our future growth.

3) We have launched the new brand “HONGJIANG” for cutting tools and seek for partner globally. Now it is the right time to cooperate with us and take an advanced position in our sales network.

Q: What is your brand positioning?

A:

1). Quality positioning: HONGJIANG brand aims at establishing itself as a leading brand and competing in a global market by supplying premium quality products.

2). Price positioning: We provide our products with the same quality as those international brands at more reasonable prices.

Q: Is application engineer available when needed?

A: Yes, we provide online training and technical support. When any tough challenges are faced by user, we will send our application engineer to provide on-site technical support at customer's site.

A: Yes, We are a professional cutting tools manufacturer and has its own factory based in Xiamen. We produce in-house the carbide rods, end mills, drill bits, indexable inserts, etc.

Q: Can you supply with drawing or on an ODM basis?

A: Yes, We can supply customized products.

1) We can produce according to your drawings;

2) We can supply goods with medium-sized packaging without our logo, then you can repack at your side with your brand packaging;

3) If volume is big, we can pack at our side with your brand packaging.

Q: Why we cooperate with you?

A: There are some reasons:

1) We are a company with adequate production machines, inspection instruments, which can supply good quality products with reasonable price;

2) We enter new cutting tool area with skilled personnel who have worked in industry-renowned companies for years, which found a basis for our future growth.

3) We have launched the new brand “HONGJIANG” for cutting tools and seek for partner globally. Now it is the right time to cooperate with us and take an advanced position in our sales network.

Q: What is your brand positioning?

A:

1). Quality positioning: HONGJIANG brand aims at establishing itself as a leading brand and competing in a global market by supplying premium quality products.

2). Price positioning: We provide our products with the same quality as those international brands at more reasonable prices.

Q: Is application engineer available when needed?

A: Yes, we provide online training and technical support. When any tough challenges are faced by user, we will send our application engineer to provide on-site technical support at customer's site.