Высококачественная прецизионная 5-осевая обработка с ЧПУ для автозапчастей мелкая металлическая медная Алюминиевая

- Категории: >>>

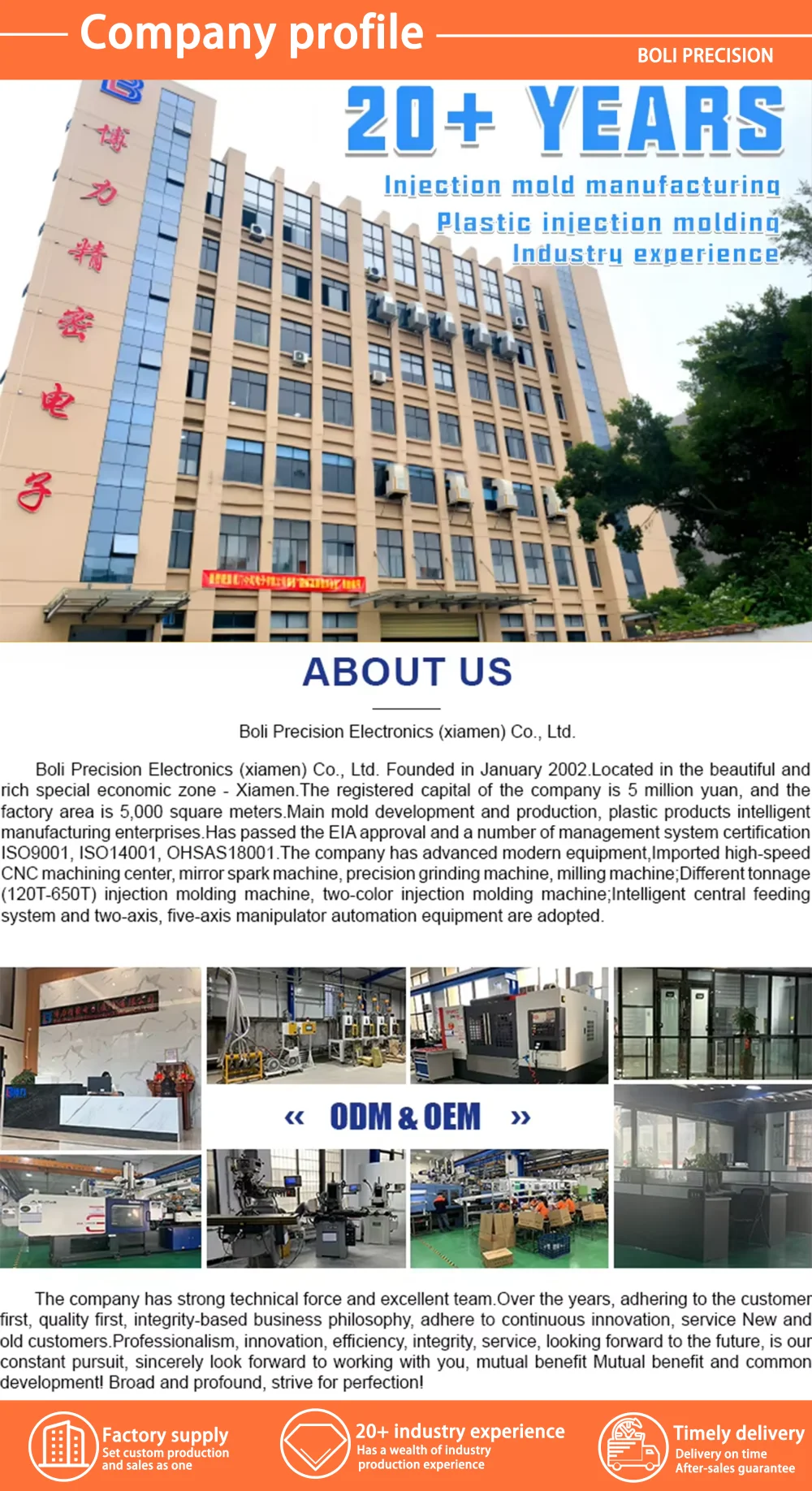

- Поставщик: Boli,Precision,Electronics,(xiamen),Co.,Ltd.Boli,Ltd.

Поделиться:

Описание и отзывы

Характеристики

Materials | Aluminum Alloy ADC12, ADC10 A360,A380, A356 | ||||||

Magnesium alloy AZ91D,AM60B | |||||||

Zinc alloy ZA3#,ZA5#,ZA8# | |||||||

Processing technology | Design→Mold making→tappin→CNC machining→polishing→surface treatment→assembly→product inspection→packaging→shipment | ||||||

Allowance | ±0.005mm | ||||||

Surface treatment | Powder spraying, oil spraying, sandblasting, polishing, grinding, passivation, chromium plating, zinc plating, nickel plating, electrophoresis, anodizing, etc | ||||||

Quality system and testing | ISO9001,SGS test report | ||||||

Quality inspection | 100% check appearance and size | ||||||

Main testing equipment | Three-dimensional detector, automatic image measuring instrument, salt spray testing machine, air tightness detector, dynamic balance detector | ||||||

Peculiarity And advantage | 1,high processing accuracy, flatness within 0.1mm. 2,high strength, not easy to deformation, with good electrical and thermal conductivity. 3,high surface finish, the surface roughness after processing is Ra1.6. 4,high processing precision, no gap assembly structure. 5,no particles, no pitting, appearance without peeling paint. 6,smooth appearance, strong corrosion resistance. 7,Through 20,000 wear resistance tests. 8,Pass 96-hour salt spray test. 9,through the coating adhesion test, scratch resistance test. 10,Passed the hundred test and 3M glue test. 11. Pass the film thickness test. | ||||||

Application field | Intelligent automation equipment, mechanical parts, medical devices, auto and motorcycle parts, power tools, home appliance parts,LED lighting parts,3C products, other metal structural parts. | ||||||

FAQ

Q1:What's kinds of information you need for quote?

A1:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS

Q2. How Fast Can I Get My Parts?

A2. We can fill orders quickly, but the delivery time depends on several factors such as the complexity of the manufacturing process, the number of orders and the delivery time section. We will finish the mold production and send the sample within 7-14 days.

Q3.Can we get some samples before mass production?

A3:Absolutely

Q4. Can Injection Products Be Surface Treated? What Are The Surface Treatments?

A4. No problem at all.Surface treatment: spray paint, silk screen,electroplating, etc.

Q5.Are you a trading company or factory?

A5:Our 5000+ square meters of dust-free production base, 10 experienced engineers, more than 100 excellent employees.

Q6.What certificates or qualifications does your company have?

A6. Company certification :CE, ISO, ROHS, product patent certificate and so on. Every order, we manufacture our products to the highest standards.

Q7.I Want To Protect My IP. Are My Designs Secure?

A7.We values privacy and security with the utmost seriousness and will happily sign a non-disclosure agreement (NDA) at your request,giving you peace of mind about your intellectual property.

A1:Kindly please provide the product drawing in PDF,and will be better you can provde in STEP or IGS

Q2. How Fast Can I Get My Parts?

A2. We can fill orders quickly, but the delivery time depends on several factors such as the complexity of the manufacturing process, the number of orders and the delivery time section. We will finish the mold production and send the sample within 7-14 days.

Q3.Can we get some samples before mass production?

A3:Absolutely

Q4. Can Injection Products Be Surface Treated? What Are The Surface Treatments?

A4. No problem at all.Surface treatment: spray paint, silk screen,electroplating, etc.

Q5.Are you a trading company or factory?

A5:Our 5000+ square meters of dust-free production base, 10 experienced engineers, more than 100 excellent employees.

Q6.What certificates or qualifications does your company have?

A6. Company certification :CE, ISO, ROHS, product patent certificate and so on. Every order, we manufacture our products to the highest standards.

Q7.I Want To Protect My IP. Are My Designs Secure?

A7.We values privacy and security with the utmost seriousness and will happily sign a non-disclosure agreement (NDA) at your request,giving you peace of mind about your intellectual property.