Карманный фильтр баланс производительности и цены фильтрующие

- Категории: >>>

- Поставщик: Fingo-Complex,LLC

Поделиться:

Описание и отзывы

Характеристики

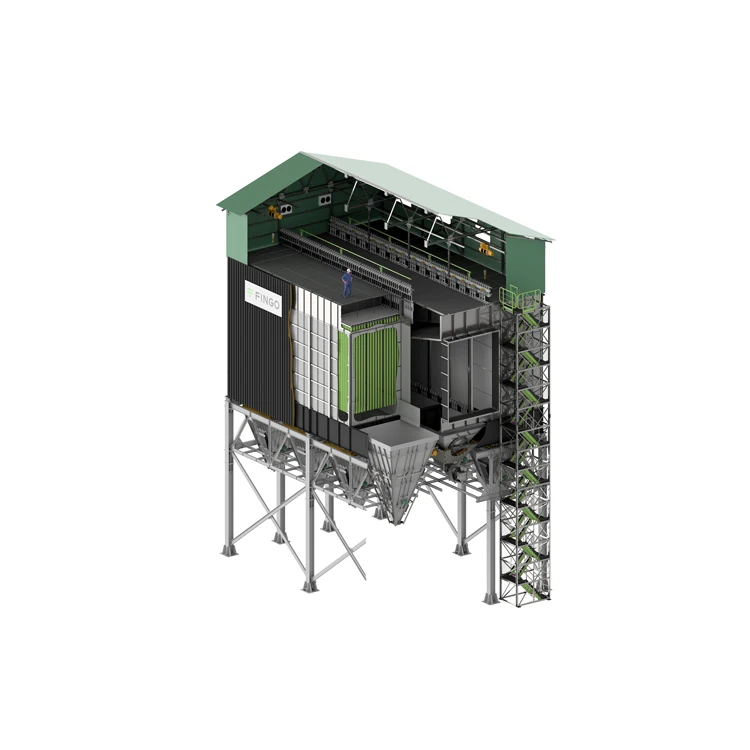

Pocket filter balance of performance and price, filter bags

Bag / Fabric Filter:

FINGO bag filters are designed for dust removal of non-aggressive non-explosive process gases and aspiration air. Design flexibility makes it possible to select the optimal physical and technical characteristics of the filter for a wide range of conditions. The filter is designed and engineered for continuous operation with minimal maintenance. Routine maintenance is usually performed without disconnection of the filter.

Bag filter with pulse-jet consists of a series of filter sleeves, round in shape, suspended from a tube sheet separating the camera dusted and cleaned the air inside the compartment.

Each sleeve has an internal wire frame that supports the sleeve and prevents its damage. Dusty gas enters the intake manifold of the filter through the existing system of channels.

Dust is collected on the outer surface of the filter medium, which allows only the purified gases to pass into the upper part above the pipe grate and further to the exhaust channel and exhaust pipe.

The dust is removed from the hoses by means of compressed air pulses when the pressure drop reaches a predetermined limit value.

During the regeneration process, the dust falls into the bins and then into the dust transport system.

|  |

Fingo Complex

FINGO is a leading Russian manufacturer and supplier of innovative air pollution control technology. The company was founded in 1944 and we are currently the Russian market leader.

We offer a wide range of gas-purification filters for heavy industries which are manufactured at our own factory which is located 200 kilometers away from Moscow. We produce dry and wet electrostatic precipitators, fabric filters, scrubbers, cyclones and offer a wide range of services in our the only full-cycle gas-purification plant in Russia.

Over the years, FINGO has supplied and installed more than 3000 industrial-sized filters in 56 countries around the world, and has also received more than 50 patents for inventions in the field of ecology and gas purification.

We supply turnkey complete industrial filters, as well as sets of internal equipment and spare parts for existing gas treatment plants for repair and reconstruction.

The company employees 230 staff and our Head Office is based in Moscow.

FINGO's full-format engineering center incorporates over 35 professionals with extensive experience in the development of gas cleaning equipment in international companies, including GE, Alstom, ZVVZ, E.ON, etc.

In terms of efficiency, FINGO designs, manufactures and uses the most advanced equipment that matches out competitors worldwide, providing the highest degree of purification, up to 99.97% (less than 10 mg/Nm3), and meeting the strictest ecological norms and the European BAT standards.

FINGO is the only manufacturer of gas cleaning equipment in the Union of former Soviet republics (CIS), which is certified by the TUV Rheinland international bureau for compliance with the requirements of the European standard of the quality management system in welding production EN 1090 and the European standard in welding production EN ISO 3834-2: 2005, which comply with approved standards and requirements for manufactured metal products set by the European Union.

Our gas treatment equipment has been certificated by the European Union and this allows FINGO to display the CE marking.

The advantages of FINGO's equipment include:

optimum metal consumption -CAPEX reduction

extended service life and service intervals -OPEX reduction

advanced reliability for severe environments

Russian low regional cost base ensures our prices are very competitive with the guarantee of high quality and excellent post-service support

The mission of FINGO is to provide world-class gas-purification equipment and services at a Russian price in order to reduce air-pollution and create a healthier environment.

How to contact?

See Contacts section

Delivery method?

Express delivery or standart shipping

Payment Methods?

Bank transfer